What is Global Seal Support Systems Market?

The Global Seal Support Systems Market refers to the worldwide industry focused on the production, distribution, and maintenance of systems that support mechanical seals in various industrial applications. These systems are crucial for ensuring the reliability and efficiency of mechanical seals, which are used to prevent leakage of fluids in rotating equipment such as pumps, compressors, and mixers. The market encompasses a wide range of products, including seal support systems for both wet and dry seals, and caters to various industries like oil and gas, chemical processing, power generation, and water treatment. The demand for these systems is driven by the need for enhanced operational efficiency, reduced maintenance costs, and compliance with stringent environmental regulations. As industries continue to expand and modernize, the Global Seal Support Systems Market is expected to grow, offering innovative solutions to meet the evolving needs of industrial applications.

Mechanical Seal Support Systems, Dry Gas Seal Support Systems in the Global Seal Support Systems Market:

Mechanical Seal Support Systems are designed to provide the necessary environment for mechanical seals to operate effectively. These systems typically include components such as reservoirs, heat exchangers, filters, and pumps that work together to control the temperature, pressure, and cleanliness of the sealing environment. By maintaining optimal conditions, mechanical seal support systems help extend the life of the seals, reduce downtime, and improve overall equipment performance. On the other hand, Dry Gas Seal Support Systems are used in applications where traditional wet seals are not suitable. These systems utilize a thin film of gas, usually nitrogen or air, to create a barrier between the rotating and stationary parts of the equipment. Dry gas seals are particularly advantageous in high-speed and high-pressure applications, as they offer low friction, minimal wear, and reduced energy consumption. Both types of seal support systems play a critical role in ensuring the reliability and efficiency of industrial processes, and their adoption is driven by the need for improved performance, safety, and environmental compliance.

Oil & Gas, Coal Chemical Industry, Pipeline industry, Others in the Global Seal Support Systems Market:

The Global Seal Support Systems Market finds extensive usage in various industries, including oil and gas, coal chemical industry, pipeline industry, and others. In the oil and gas sector, seal support systems are essential for maintaining the integrity of mechanical seals in pumps, compressors, and other rotating equipment used in exploration, production, and refining processes. These systems help prevent leaks, reduce maintenance costs, and ensure compliance with environmental regulations. In the coal chemical industry, seal support systems are used to enhance the performance and reliability of equipment involved in the processing of coal into chemicals, fuels, and other products. By providing a controlled environment for mechanical seals, these systems help minimize downtime and improve operational efficiency. The pipeline industry also relies on seal support systems to ensure the safe and efficient transportation of liquids and gases through pipelines. These systems help maintain the integrity of seals in pumps and compressors, reducing the risk of leaks and ensuring the smooth operation of pipeline networks. Other industries, such as power generation, water treatment, and pharmaceuticals, also benefit from the use of seal support systems to enhance the performance and reliability of their equipment. Overall, the Global Seal Support Systems Market plays a vital role in supporting the efficient and safe operation of various industrial processes.

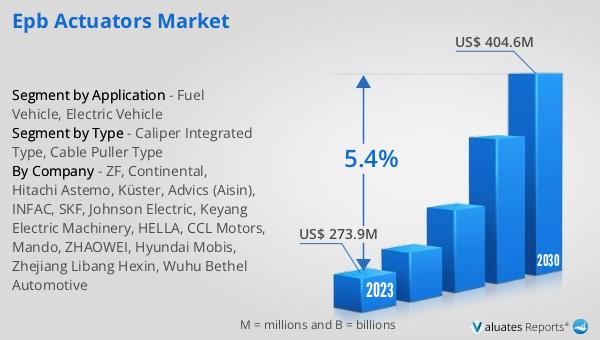

Global Seal Support Systems Market Outlook:

The global Seal Support Systems market was valued at US$ 1503.6 million in 2023 and is anticipated to reach US$ 2388.2 million by 2030, witnessing a CAGR of 6.6% during the forecast period from 2024 to 2030. This significant growth is driven by the increasing demand for reliable and efficient sealing solutions across various industries. As companies strive to enhance operational efficiency, reduce maintenance costs, and comply with stringent environmental regulations, the adoption of advanced seal support systems is expected to rise. The market's expansion is also fueled by technological advancements and the development of innovative products that cater to the evolving needs of industrial applications. With the continuous growth of industries such as oil and gas, chemical processing, and power generation, the Global Seal Support Systems Market is poised for substantial growth in the coming years.

| Report Metric | Details |

| Report Name | Seal Support Systems Market |

| Accounted market size in 2023 | US$ 1503.6 million |

| Forecasted market size in 2030 | US$ 2388.2 million |

| CAGR | 6.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | John Crane, EagleBurgmann, Flowserve, AESSEAL, Meccanotecnica Umbra, VULCAN, Garlock, Sunnyseal, Oerlikon Balzers, KSB, Colossus, Sulzer, Flex-A-Seal, Chesterton, Valmet, Qseals, Ekato, Xi'an Yonghua, Fluiten, James Walker, Sinoseal Holding, Dandong Colossus Group, Chengdu YitongSeal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |