What is Global NdFeB Bonded Magnets Market?

The Global NdFeB Bonded Magnets Market refers to the worldwide industry focused on the production, distribution, and application of bonded neodymium-iron-boron (NdFeB) magnets. These magnets are known for their strong magnetic properties and are created by combining NdFeB powder with a binding material, typically a type of plastic or resin. This process results in magnets that are not only powerful but also versatile and customizable in shape and size. The market encompasses various sectors, including automotive, electronics, household appliances, and medical equipment, where these magnets are used for their efficiency and reliability. The demand for NdFeB bonded magnets is driven by their superior performance in miniaturized applications and their ability to maintain magnetic strength over time. As industries continue to innovate and seek more efficient solutions, the global NdFeB bonded magnets market is expected to grow, offering new opportunities for manufacturers and suppliers.

Injection Molding, Pressing in the Global NdFeB Bonded Magnets Market:

Injection molding and pressing are two primary manufacturing techniques used in the production of NdFeB bonded magnets. Injection molding involves melting the NdFeB powder mixed with a binding agent and then injecting it into a mold to form the desired shape. This method allows for the creation of complex and precise geometries, making it ideal for applications that require intricate designs and tight tolerances. The process begins with the preparation of the NdFeB powder, which is mixed with a thermoplastic binder. The mixture is then heated until it becomes a viscous liquid, which is injected into a mold cavity under high pressure. Once the material cools and solidifies, the mold is opened, and the finished magnet is ejected. Injection molding is highly efficient and suitable for mass production, as it can produce large quantities of magnets with consistent quality and minimal waste. On the other hand, pressing involves compacting the NdFeB powder with a binder into a desired shape using a press. This method is typically used for simpler shapes and larger magnets. The process starts with the preparation of the NdFeB powder, which is mixed with a binder to form a homogeneous mixture. The mixture is then placed into a die cavity, where it is subjected to high pressure to compact the powder into a solid form. After pressing, the compacted magnet is removed from the die and undergoes a curing process to harden the binder and enhance the magnetic properties. Pressing is advantageous for producing magnets with high density and uniformity, making it suitable for applications that require strong magnetic performance. Both injection molding and pressing offer unique benefits and are chosen based on the specific requirements of the application. The choice between the two methods depends on factors such as the complexity of the design, production volume, and desired magnetic properties. As the demand for NdFeB bonded magnets continues to grow, manufacturers are constantly exploring new techniques and materials to improve the efficiency and performance of these magnets.

Auto Accessories, Electrical and Electronics, Household Appliances, Medical Equipment in the Global NdFeB Bonded Magnets Market:

NdFeB bonded magnets are widely used in various industries due to their strong magnetic properties and versatility. In the automotive sector, these magnets are essential components in various auto accessories, such as sensors, motors, and actuators. They are used in electric power steering systems, anti-lock braking systems, and other advanced driver-assistance systems (ADAS) to enhance vehicle performance and safety. The ability of NdFeB bonded magnets to provide high torque and precise control makes them ideal for these applications. In the electrical and electronics industry, NdFeB bonded magnets are used in a wide range of devices, including hard disk drives, mobile phones, and audio equipment. Their compact size and strong magnetic field make them suitable for miniaturized applications, where space and weight are critical factors. These magnets are also used in electric motors and generators, where their high efficiency and reliability contribute to the overall performance of the devices. In household appliances, NdFeB bonded magnets are found in various products, such as vacuum cleaners, washing machines, and refrigerators. They are used in motors, sensors, and actuators to improve the efficiency and functionality of these appliances. For example, in vacuum cleaners, NdFeB bonded magnets are used in the motor to provide high suction power and energy efficiency. In medical equipment, NdFeB bonded magnets play a crucial role in devices such as MRI machines, hearing aids, and pacemakers. Their strong magnetic properties and biocompatibility make them suitable for medical applications, where precision and reliability are essential. In MRI machines, NdFeB bonded magnets are used to generate the strong magnetic fields required for imaging, while in hearing aids and pacemakers, they provide the necessary magnetic force for proper functioning. The versatility and performance of NdFeB bonded magnets make them indispensable in these industries, driving the demand for these magnets in various applications.

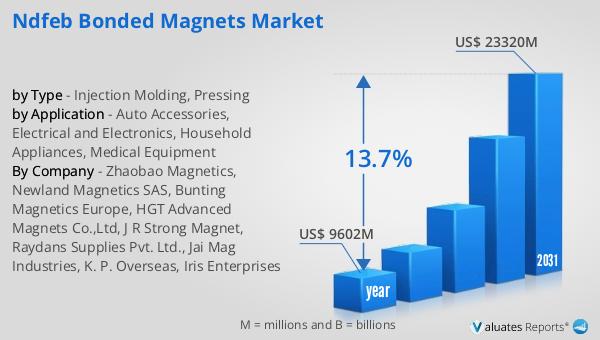

Global NdFeB Bonded Magnets Market Outlook:

The global NdFeB Bonded Magnets market was valued at US$ 7,820 million in 2023 and is anticipated to reach US$ 18,480 million by 2030, witnessing a CAGR of 13.7% during the forecast period 2024-2030. This significant growth is driven by the increasing demand for high-performance magnets in various industries, including automotive, electronics, household appliances, and medical equipment. The superior magnetic properties and versatility of NdFeB bonded magnets make them ideal for a wide range of applications, from electric motors and sensors to medical devices and household appliances. As industries continue to innovate and seek more efficient solutions, the demand for NdFeB bonded magnets is expected to rise, contributing to the market's growth. The market's expansion is also supported by advancements in manufacturing techniques, such as injection molding and pressing, which enable the production of high-quality magnets with complex geometries and precise specifications. These advancements help manufacturers meet the growing demand for customized and efficient magnetic solutions. Additionally, the increasing focus on sustainability and energy efficiency in various industries is driving the adoption of NdFeB bonded magnets, as they offer high performance with minimal energy consumption. As a result, the global NdFeB bonded magnets market is poised for significant growth in the coming years, offering new opportunities for manufacturers and suppliers to capitalize on the rising demand for these versatile and powerful magnets.

| Report Metric | Details |

| Report Name | NdFeB Bonded Magnets Market |

| Accounted market size in 2023 | US$ 7820 million |

| Forecasted market size in 2030 | US$ 18480 million |

| CAGR | 13.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Zhaobao Magnetics, Newland Magnetics SAS, Bunting Magnetics Europe, HGT Advanced Magnets Co.,Ltd, J R Strong Magnet, Raydans Supplies Pvt. Ltd., Jai Mag Industries, K. P. Overseas, Iris Enterprises |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |