What is Global Sonic Industrial Imager Market?

The Global Sonic Industrial Imager Market refers to the industry focused on the development, production, and application of sonic imaging technology for industrial purposes. Sonic industrial imagers use sound waves to create visual representations of objects, structures, or environments, which can be crucial for various industrial applications. These devices are particularly useful in scenarios where traditional imaging methods, such as optical cameras or X-rays, may not be effective or feasible. The technology is employed in a wide range of industries, including manufacturing, transportation, energy, and utilities, to detect flaws, monitor conditions, and ensure safety and efficiency. The market for these devices is growing as industries increasingly recognize the value of advanced imaging technologies for improving operational efficiency and safety. The global market for sonic industrial imagers is driven by technological advancements, increasing industrial automation, and the need for precise and reliable inspection methods. As industries continue to evolve and adopt more sophisticated technologies, the demand for sonic industrial imagers is expected to rise, making it a significant area of interest for manufacturers and investors alike.

Stationary, Handheld in the Global Sonic Industrial Imager Market:

In the Global Sonic Industrial Imager Market, devices can be broadly categorized into stationary and handheld imagers. Stationary sonic industrial imagers are typically installed in fixed locations within industrial facilities. These devices are often integrated into production lines or specific inspection stations where continuous or periodic monitoring is required. Stationary imagers are ideal for applications that demand high precision and consistency, such as quality control in manufacturing processes, structural health monitoring in large infrastructure projects, and continuous surveillance in critical facilities like power plants. These imagers are designed to operate in harsh industrial environments, providing reliable and accurate imaging data over extended periods. On the other hand, handheld sonic industrial imagers offer greater flexibility and mobility. These portable devices are used by technicians and engineers to perform on-the-spot inspections and diagnostics. Handheld imagers are particularly useful in scenarios where access to the area of interest is limited or where the inspection needs to be conducted in various locations. They are commonly used in maintenance and repair operations, field inspections, and troubleshooting tasks. The portability of handheld imagers allows for quick and efficient assessments, making them an essential tool for industries that require frequent and diverse inspections. Both stationary and handheld sonic industrial imagers play a crucial role in enhancing the efficiency and safety of industrial operations. The choice between the two depends on the specific requirements of the application, such as the need for continuous monitoring versus the need for mobility and flexibility. As technology advances, the capabilities of both stationary and handheld imagers continue to improve, offering higher resolution, better accuracy, and more user-friendly interfaces. This ongoing development ensures that sonic industrial imagers remain a vital component of modern industrial practices, helping industries to maintain high standards of quality, safety, and efficiency.

Electricity, Manufacturing, Transportation, New Energy in the Global Sonic Industrial Imager Market:

The Global Sonic Industrial Imager Market finds extensive usage across various sectors, including electricity, manufacturing, transportation, and new energy. In the electricity sector, sonic industrial imagers are used to inspect and monitor electrical infrastructure, such as power lines, transformers, and substations. These devices help in detecting faults, assessing the condition of equipment, and preventing potential failures, thereby ensuring the reliability and safety of the electrical grid. In manufacturing, sonic industrial imagers are employed for quality control and inspection purposes. They are used to detect defects in materials, monitor the integrity of components, and ensure that products meet the required standards. This helps manufacturers to maintain high levels of quality and reduce the risk of product recalls. In the transportation sector, sonic industrial imagers are used to inspect and maintain vehicles, aircraft, and other transportation infrastructure. They help in identifying structural issues, detecting wear and tear, and ensuring that transportation systems are safe and reliable. This is particularly important in industries such as aviation and railways, where safety is of paramount importance. In the new energy sector, sonic industrial imagers are used to inspect and monitor renewable energy infrastructure, such as wind turbines and solar panels. These devices help in detecting issues, assessing the condition of equipment, and ensuring that renewable energy systems operate efficiently and reliably. The use of sonic industrial imagers in these sectors highlights their versatility and importance in maintaining the safety, efficiency, and reliability of critical infrastructure.

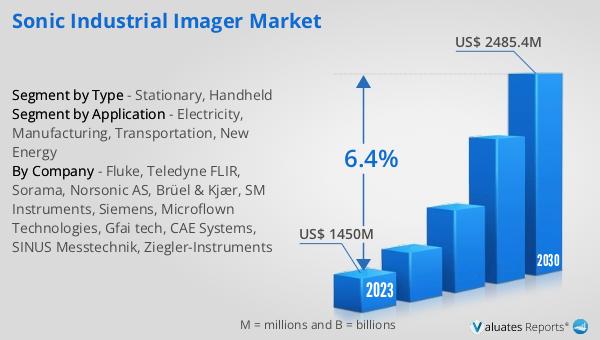

Global Sonic Industrial Imager Market Outlook:

The global Sonic Industrial Imager market was valued at US$ 1450 million in 2023 and is anticipated to reach US$ 2485.4 million by 2030, witnessing a CAGR of 6.4% during the forecast period from 2024 to 2030. This significant growth reflects the increasing demand for advanced imaging technologies across various industries. The market's expansion is driven by the need for precise and reliable inspection methods, which are essential for maintaining high standards of quality, safety, and efficiency in industrial operations. As industries continue to evolve and adopt more sophisticated technologies, the demand for sonic industrial imagers is expected to rise. This growth also underscores the importance of ongoing technological advancements in the field, which are enhancing the capabilities of these devices and making them more accessible and user-friendly. The projected growth of the global Sonic Industrial Imager market highlights the critical role that these devices play in modern industrial practices and their potential to drive further innovation and efficiency in the years to come.

| Report Metric | Details |

| Report Name | Sonic Industrial Imager Market |

| Accounted market size in 2023 | US$ 1450 million |

| Forecasted market size in 2030 | US$ 2485.4 million |

| CAGR | 6.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fluke, Teledyne FLIR, Sorama, Norsonic AS, Brüel & Kjær, SM Instruments, Siemens, Microflown Technologies, Gfai tech, CAE Systems, SINUS Messtechnik, Ziegler-Instruments |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |