What is Global OrgaAnti-stick Additives Market?

The Global OrgaAnti-stick Additives Market refers to the industry focused on the production and distribution of additives that prevent materials from sticking to surfaces. These additives are crucial in various manufacturing processes where sticking can cause significant issues, such as in the production of plastics, coatings, and sealants. The market encompasses a wide range of products designed to enhance the performance and durability of materials by reducing friction and preventing adhesion. This not only improves the quality of the final products but also increases efficiency and reduces waste in manufacturing processes. The demand for OrgaAnti-stick additives is driven by their application in numerous industries, including automotive, construction, packaging, and electronics, where they play a vital role in ensuring product reliability and longevity. As industries continue to seek ways to improve product performance and manufacturing efficiency, the Global OrgaAnti-stick Additives Market is expected to grow, driven by technological advancements and increasing awareness of the benefits of these additives.

Organic, Inorganic in the Global OrgaAnti-stick Additives Market:

Organic and inorganic additives are two primary categories within the Global OrgaAnti-stick Additives Market, each with distinct characteristics and applications. Organic anti-stick additives are derived from natural sources or synthesized through organic chemistry. These additives are typically biodegradable and environmentally friendly, making them a preferred choice in industries that prioritize sustainability. Organic additives often include substances like fatty acids, waxes, and silicone-based compounds. They are known for their excellent compatibility with various materials and their ability to provide effective anti-stick properties without compromising the integrity of the base material. On the other hand, inorganic anti-stick additives are derived from mineral sources and are often synthesized through inorganic chemical processes. These additives include materials like silica, talc, and certain metal oxides. Inorganic additives are valued for their thermal stability, mechanical strength, and resistance to chemical degradation. They are particularly useful in applications where high temperatures or harsh chemical environments are involved. Both organic and inorganic additives play crucial roles in enhancing the performance of materials in different ways. Organic additives are often used in applications where flexibility, biodegradability, and environmental impact are key considerations. For example, in the food packaging industry, organic anti-stick additives are used to ensure that food products do not adhere to packaging materials, thereby maintaining product quality and safety. In contrast, inorganic additives are more commonly used in industrial applications where durability and resistance to extreme conditions are essential. For instance, in the automotive industry, inorganic anti-stick additives are used in coatings and sealants to protect vehicle components from wear and tear, corrosion, and high temperatures. The choice between organic and inorganic additives depends on the specific requirements of the application, including factors such as environmental impact, performance characteristics, and cost considerations. As industries continue to evolve and new materials and technologies emerge, the demand for both organic and inorganic anti-stick additives is expected to grow, driven by the need for improved performance, sustainability, and efficiency in manufacturing processes.

Plastic, Coating, Sealant in the Global OrgaAnti-stick Additives Market:

The usage of Global OrgaAnti-stick Additives Market in plastics, coatings, and sealants is extensive and varied, reflecting the diverse applications and benefits of these additives. In the plastics industry, anti-stick additives are used to enhance the processing and performance of plastic materials. These additives help to reduce friction and prevent the adhesion of plastic to molds and other surfaces during manufacturing, thereby improving the efficiency and quality of the production process. They also contribute to the durability and longevity of plastic products by reducing wear and tear. For example, in the production of plastic films and sheets, anti-stick additives ensure smooth processing and prevent the materials from sticking to each other or to the equipment, resulting in higher quality products with fewer defects. In the coatings industry, anti-stick additives are used to improve the performance and durability of various types of coatings. These additives help to create a smooth, non-stick surface that resists dirt, dust, and other contaminants, thereby enhancing the appearance and longevity of the coated surfaces. They are commonly used in automotive coatings, where they help to protect vehicle exteriors from scratches, corrosion, and environmental damage. Anti-stick additives are also used in industrial coatings, where they provide resistance to chemicals, heat, and abrasion, thereby extending the life of machinery and equipment. In the sealants industry, anti-stick additives play a crucial role in ensuring the effectiveness and durability of sealant products. These additives help to prevent the sealant from sticking to unwanted surfaces during application, thereby ensuring a clean and precise seal. They also enhance the flexibility and adhesion properties of the sealant, allowing it to maintain its effectiveness over time. For example, in the construction industry, anti-stick additives are used in sealants to ensure that they adhere properly to building materials and provide a long-lasting seal that resists moisture, temperature changes, and other environmental factors. Overall, the usage of anti-stick additives in plastics, coatings, and sealants is essential for improving the performance, efficiency, and durability of these materials. As industries continue to seek ways to enhance product quality and manufacturing processes, the demand for anti-stick additives is expected to grow, driven by their ability to provide significant benefits in a wide range of applications.

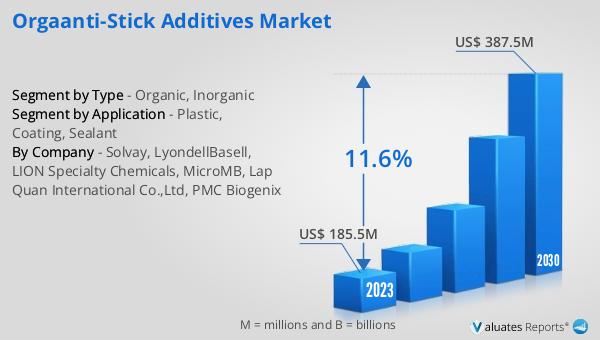

Global OrgaAnti-stick Additives Market Outlook:

The global OrgaAnti-stick Additives market, valued at US$ 185.5 million in 2023, is projected to reach US$ 387.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 11.6% during the forecast period from 2024 to 2030. This significant growth underscores the increasing demand for anti-stick additives across various industries. The market's expansion is driven by the need for improved manufacturing efficiency, product quality, and durability in sectors such as automotive, construction, packaging, and electronics. As industries continue to innovate and adopt new technologies, the role of anti-stick additives becomes even more critical in ensuring the reliability and performance of materials. The projected growth also highlights the importance of both organic and inorganic additives in meeting the diverse requirements of different applications. Organic additives, known for their biodegradability and environmental friendliness, are increasingly preferred in industries that prioritize sustainability. In contrast, inorganic additives, valued for their thermal stability and resistance to harsh conditions, are essential in industrial applications where durability is paramount. The market outlook indicates a robust future for the Global OrgaAnti-stick Additives Market, driven by technological advancements, increasing awareness of the benefits of these additives, and the ongoing demand for high-performance materials in various industries.

| Report Metric | Details |

| Report Name | OrgaAnti-stick Additives Market |

| Accounted market size in 2023 | US$ 185.5 million |

| Forecasted market size in 2030 | US$ 387.5 million |

| CAGR | 11.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Solvay, LyondellBasell, LION Specialty Chemicals, MicroMB, Lap Quan International Co.,Ltd, PMC Biogenix |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |