What is Global Molybdenum Disilicide Heating Element Market?

The Global Molybdenum Disilicide Heating Element Market is a specialized segment within the broader heating element industry, focusing on the use of molybdenum disilicide (MoSi2) as a key material. Molybdenum disilicide is a highly effective compound known for its exceptional ability to withstand high temperatures, making it ideal for applications that require consistent and reliable heating at elevated temperatures. These heating elements are primarily used in industrial and laboratory furnaces, where precise temperature control is crucial. The market is driven by the demand for high-performance heating solutions in various industries, including metallurgy, ceramics, and electronics. As industries continue to evolve and require more advanced materials and processes, the need for reliable and efficient heating elements like those made from molybdenum disilicide is expected to grow. The market is characterized by a focus on innovation and quality, with manufacturers striving to improve the performance and durability of their products to meet the stringent requirements of modern industrial applications. Overall, the Global Molybdenum Disilicide Heating Element Market plays a critical role in supporting the technological advancements and operational efficiency of industries that rely on high-temperature processes.

1700°C Grade, 1800°C Grade, 1900°C Grade in the Global Molybdenum Disilicide Heating Element Market:

The Global Molybdenum Disilicide Heating Element Market is segmented into different grades based on the maximum temperature they can withstand, namely 1700°C, 1800°C, and 1900°C. Each grade serves specific applications and industries, offering unique benefits and limitations. The 1700°C grade is typically used in applications where moderate high temperatures are required. It is suitable for processes that do not demand the extreme heat resistance of higher grades but still require reliable performance at elevated temperatures. This grade is often used in smaller industrial furnaces and laboratory settings where precise temperature control is necessary but not at the highest extremes. The 1800°C grade is the most widely used segment within the market, accounting for over 50% of the product share. This grade offers a balance between cost and performance, making it ideal for a wide range of industrial applications. It is commonly used in the production of ceramics, glass, and metals, where consistent and high temperatures are essential for quality and efficiency. The 1800°C grade is favored for its durability and ability to maintain stable temperatures over prolonged periods, which is crucial for processes that require continuous operation. The 1900°C grade represents the pinnacle of performance within the molybdenum disilicide heating element market. It is designed for the most demanding applications that require the highest levels of heat resistance and stability. This grade is used in specialized industrial processes, such as the production of advanced ceramics and high-performance alloys, where even slight variations in temperature can significantly impact the quality of the final product. The 1900°C grade is also used in research and development settings, where cutting-edge materials and technologies are being developed. Despite its higher cost, the 1900°C grade is valued for its exceptional performance and reliability in the most challenging environments. Each grade within the Global Molybdenum Disilicide Heating Element Market offers distinct advantages, allowing industries to choose the most appropriate solution for their specific needs. As technology advances and the demand for high-performance materials grows, the importance of selecting the right grade of molybdenum disilicide heating element becomes increasingly critical. Manufacturers continue to innovate and improve their products to meet the evolving needs of their customers, ensuring that the market remains dynamic and responsive to the challenges of modern industrial applications.

Industrial Furnaces, Laboratory Furnaces in the Global Molybdenum Disilicide Heating Element Market:

The usage of Global Molybdenum Disilicide Heating Elements in industrial and laboratory furnaces is a testament to their versatility and effectiveness in high-temperature applications. In industrial furnaces, these heating elements are crucial for processes that require consistent and reliable heat. Industries such as metallurgy, ceramics, and glass manufacturing rely heavily on these elements to achieve the precise temperatures needed for their operations. In metallurgy, for instance, molybdenum disilicide heating elements are used to melt and refine metals, ensuring that the materials reach the necessary temperatures for alloying and casting. The ability to maintain stable temperatures is essential for producing high-quality metal products with the desired properties. Similarly, in the ceramics industry, these heating elements are used in kilns to fire ceramics at high temperatures, ensuring that the final products are strong, durable, and free from defects. The glass industry also benefits from the use of molybdenum disilicide heating elements, as they provide the consistent heat required to melt and shape glass into various forms. In laboratory furnaces, molybdenum disilicide heating elements are used for research and development purposes, where precise temperature control is paramount. These furnaces are often used in scientific research, material testing, and quality control processes. The ability to achieve and maintain high temperatures allows researchers to study the properties of materials under extreme conditions, leading to the development of new materials and technologies. In quality control, laboratory furnaces equipped with molybdenum disilicide heating elements are used to test the heat resistance and durability of materials, ensuring that they meet industry standards and specifications. The versatility of molybdenum disilicide heating elements makes them an invaluable tool in both industrial and laboratory settings. Their ability to withstand high temperatures and provide consistent heat output ensures that they can meet the demands of various applications, from large-scale industrial processes to precise laboratory experiments. As industries continue to evolve and require more advanced materials and processes, the role of molybdenum disilicide heating elements in supporting these advancements becomes increasingly important. Manufacturers are continually working to improve the performance and efficiency of these elements, ensuring that they remain a critical component in the pursuit of technological innovation and operational excellence.

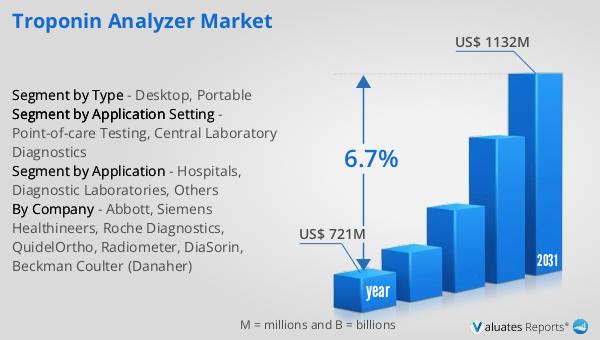

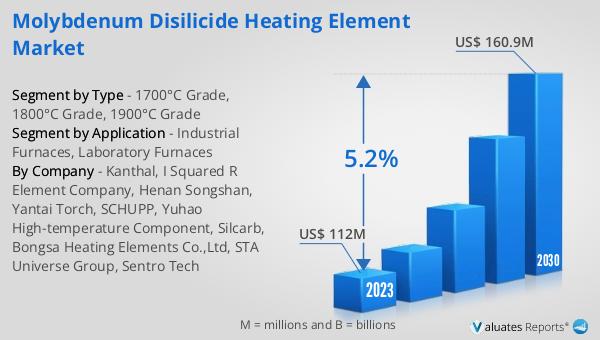

Global Molybdenum Disilicide Heating Element Market Outlook:

The global market for Molybdenum Disilicide Heating Elements was valued at approximately $124 million in 2024, with projections indicating a growth to around $176 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.2% over the forecast period. The market is dominated by the top five manufacturers, who collectively hold a significant share of over 65%. This concentration of market power highlights the competitive nature of the industry and the importance of innovation and quality in maintaining a leading position. Within the product segments, the 1800°C grade stands out as the largest, accounting for more than 50% of the market share. This grade's popularity can be attributed to its balance of performance and cost, making it a preferred choice for a wide range of applications. The demand for high-performance heating solutions continues to drive the market, with industries seeking reliable and efficient options to meet their specific needs. As the market evolves, manufacturers are expected to focus on enhancing the capabilities of their products to cater to the growing demand for advanced materials and processes. The Global Molybdenum Disilicide Heating Element Market is poised for continued growth, driven by the increasing need for high-temperature solutions across various industries.

| Report Metric | Details |

| Report Name | Molybdenum Disilicide Heating Element Market |

| Accounted market size in year | US$ 124 million |

| Forecasted market size in 2031 | US$ 176 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kanthal, I Squared R Element Company, Henan Songshan, Yantai Torch, SCHUPP, Yuhao High-temperature Component, Silcarb, Bongsa Heating Elements Co.,Ltd, STA Universe Group, Sentro Tech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |