What is Global Magnetic Absolute Encoders Market?

The Global Magnetic Absolute Encoders Market is a fascinating segment within the broader field of automation and control systems. These encoders are essential components used to determine the precise position of an object, often in industrial settings. Unlike incremental encoders, which only provide relative position data, absolute encoders offer exact position information, even after a power loss. This feature makes them indispensable in applications where accuracy and reliability are paramount. The market for these encoders is driven by the increasing demand for automation across various industries, including manufacturing, automotive, and robotics. As industries strive for higher efficiency and precision, the need for reliable position feedback systems like magnetic absolute encoders grows. These devices use magnetic fields to determine position, which makes them robust and suitable for harsh environments. The global market is witnessing technological advancements, such as the integration of IoT and AI, which are further enhancing the capabilities of these encoders. As a result, the Global Magnetic Absolute Encoders Market is poised for significant growth, driven by the continuous push towards automation and the need for precise control systems in various industrial applications.

Multi-Turn Encoders, Single-Turn Encoders in the Global Magnetic Absolute Encoders Market:

In the realm of Global Magnetic Absolute Encoders Market, Multi-Turn and Single-Turn Encoders play pivotal roles. Multi-Turn Encoders are designed to track the number of complete revolutions an object makes, in addition to its position within a single turn. This capability is crucial in applications where the position needs to be tracked over multiple rotations, such as in robotics or complex machinery. These encoders use a combination of magnetic sensors and gears to count the number of turns, ensuring that even if power is lost, the encoder retains its position data. This feature is particularly beneficial in applications where resetting the position manually would be cumbersome or impractical. On the other hand, Single-Turn Encoders provide position data within a single 360-degree rotation. They are typically used in applications where the position needs to be determined within one complete turn, such as in steering systems or simple rotary applications. Single-Turn Encoders are generally simpler and more cost-effective than their multi-turn counterparts, making them suitable for less complex applications. Both types of encoders are integral to the Global Magnetic Absolute Encoders Market, serving different needs based on the complexity and requirements of the application. The choice between Multi-Turn and Single-Turn Encoders often depends on the specific needs of the application, such as the level of precision required, the environment in which the encoder will operate, and the budget constraints. As technology advances, these encoders are becoming more sophisticated, with features like higher resolution, better durability, and enhanced connectivity options. This evolution is driven by the increasing demand for automation and precision in various industries, from automotive to aerospace. The Global Magnetic Absolute Encoders Market is thus characterized by a diverse range of products, each tailored to meet the specific needs of different applications. As industries continue to evolve and demand more precise and reliable position feedback systems, the market for both Multi-Turn and Single-Turn Encoders is expected to grow, driven by the need for efficiency and accuracy in modern industrial processes.

Elevator, NC Machine Tool, Textile Machinery, Others in the Global Magnetic Absolute Encoders Market:

The Global Magnetic Absolute Encoders Market finds extensive usage across various sectors, including elevators, NC machine tools, textile machinery, and others. In the elevator industry, these encoders are crucial for ensuring the precise positioning of the elevator car. They provide accurate feedback on the car's position, which is essential for smooth and safe operation. The ability to retain position data even after a power loss ensures that elevators can resume operation without the need for manual recalibration, enhancing safety and efficiency. In NC machine tools, magnetic absolute encoders are used to provide precise position feedback for the tool's movement. This precision is vital for achieving the high levels of accuracy required in modern manufacturing processes. The encoders help in maintaining the correct tool path, ensuring that the final product meets the desired specifications. In textile machinery, these encoders are used to control the position of various components, such as rollers and spindles. The ability to provide accurate position data helps in maintaining the quality and consistency of the textile products. Other industries, such as robotics and automotive, also benefit from the use of magnetic absolute encoders. In robotics, they provide precise position feedback for the robot's joints, enabling accurate and repeatable movements. In the automotive industry, they are used in various applications, such as steering systems and throttle control, where precise position feedback is essential for optimal performance. The versatility and reliability of magnetic absolute encoders make them an indispensable component in a wide range of applications, driving their demand in the global market.

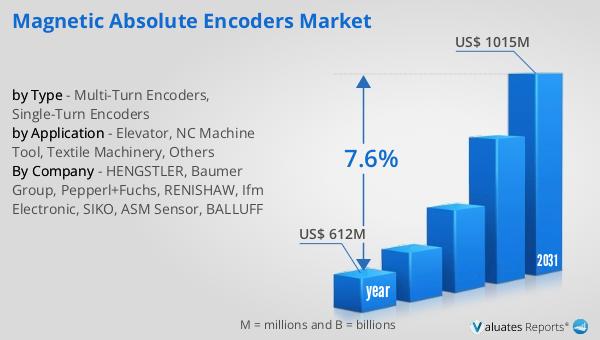

Global Magnetic Absolute Encoders Market Outlook:

The global market for Magnetic Absolute Encoders was valued at $612 million in 2024 and is projected to reach a revised size of $1,015 million by 2031, growing at a CAGR of 7.6% during the forecast period. This growth is indicative of the increasing demand for precision and reliability in various industrial applications. As industries continue to automate and seek more efficient processes, the need for accurate position feedback systems like magnetic absolute encoders becomes more pronounced. These encoders offer the advantage of retaining position data even after a power loss, making them ideal for applications where reliability is crucial. The market's growth is also driven by technological advancements, such as the integration of IoT and AI, which are enhancing the capabilities of these encoders. As a result, the Global Magnetic Absolute Encoders Market is expected to witness significant growth, driven by the continuous push towards automation and the need for precise control systems in various industrial applications. The increasing adoption of these encoders in sectors such as automotive, robotics, and manufacturing further underscores their importance in modern industrial processes. As the market continues to evolve, it is likely to see further innovations and developments, making magnetic absolute encoders an essential component in the future of industrial automation.

| Report Metric | Details |

| Report Name | Magnetic Absolute Encoders Market |

| Accounted market size in year | US$ 612 million |

| Forecasted market size in 2031 | US$ 1015 million |

| CAGR | 7.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HENGSTLER, Baumer Group, Pepperl+Fuchs, RENISHAW, Ifm Electronic, SIKO, ASM Sensor, BALLUFF |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |