What is Global Aerospace Robots Market?

The Global Aerospace Robots Market is a rapidly evolving sector that plays a crucial role in the aerospace industry. These robots are designed to perform a variety of tasks that enhance efficiency, precision, and safety in aerospace manufacturing and maintenance. The market encompasses a wide range of robotic technologies, including those used for assembly, inspection, and maintenance of aircraft and spacecraft. Aerospace robots are employed to handle complex tasks that require high precision and repeatability, such as drilling, fastening, welding, and painting. The adoption of robotics in aerospace is driven by the need to improve production rates, reduce human error, and ensure consistent quality. As the aerospace industry continues to grow, the demand for advanced robotic solutions is expected to increase, leading to further innovations and developments in this field. The integration of robotics in aerospace not only boosts productivity but also enhances safety by reducing the need for human workers to perform hazardous tasks. Overall, the Global Aerospace Robots Market is a dynamic and essential component of the aerospace industry, contributing to its advancement and efficiency.

SCARA, Articulated, Cylindrical, Cartesian, Others in the Global Aerospace Robots Market:

In the Global Aerospace Robots Market, various types of robots are utilized, each with unique characteristics and applications. SCARA (Selective Compliance Assembly Robot Arm) robots are known for their speed and precision, making them ideal for tasks such as assembly and material handling. These robots have a rigid structure that allows for high-speed operations, which is essential in the fast-paced aerospace industry. Articulated robots, on the other hand, are highly versatile and can perform a wide range of tasks due to their multiple joints and axes of rotation. This flexibility makes them suitable for complex tasks such as welding and painting, where precision and adaptability are crucial. Cylindrical robots, characterized by their cylindrical work envelope, are often used for tasks that require linear motion, such as drilling and fastening. Their design allows for efficient use of space and easy integration into existing production lines. Cartesian robots, also known as gantry robots, operate on three linear axes and are commonly used for tasks that require high precision and repeatability, such as inspection and quality control. Their straightforward design and ease of programming make them a popular choice in the aerospace industry. Other types of robots, such as collaborative robots (cobots), are also gaining traction in the aerospace sector. Cobots are designed to work alongside human workers, enhancing productivity and safety by taking over repetitive or hazardous tasks. The integration of these various types of robots in the aerospace industry is driven by the need for increased efficiency, precision, and safety. Each type of robot offers distinct advantages that cater to specific needs within the industry, contributing to the overall growth and development of the Global Aerospace Robots Market.

Drilling & Fastening, Inspection, Welding, Painting & Coating, Others in the Global Aerospace Robots Market:

The usage of robots in the Global Aerospace Robots Market spans several critical areas, each contributing to the efficiency and precision of aerospace manufacturing and maintenance. In drilling and fastening, robots are employed to perform repetitive and precise tasks that require high accuracy. These robots can drill holes and fasten components with consistent precision, reducing the risk of human error and ensuring the structural integrity of aircraft and spacecraft. In inspection, robots equipped with advanced sensors and imaging technologies are used to conduct thorough inspections of aircraft components. These robots can detect defects and anomalies that may not be visible to the human eye, ensuring the safety and reliability of aerospace products. Welding is another area where robots play a vital role. Robotic welding systems provide consistent and high-quality welds, essential for the structural integrity of aerospace components. These systems can operate in hazardous environments, reducing the risk to human workers. In painting and coating, robots offer precision and consistency, ensuring even application of paint and coatings on aircraft surfaces. This not only enhances the aesthetic appeal of the aircraft but also provides protection against environmental factors. Other applications of robots in the aerospace industry include material handling, assembly, and maintenance. Robots are used to transport materials and components within production facilities, streamlining the manufacturing process. In assembly, robots can perform complex tasks with high precision, ensuring the proper alignment and fitting of components. In maintenance, robots are used to perform routine inspections and repairs, reducing downtime and enhancing the longevity of aerospace products. Overall, the integration of robots in these areas enhances the efficiency, precision, and safety of aerospace manufacturing and maintenance, driving the growth of the Global Aerospace Robots Market.

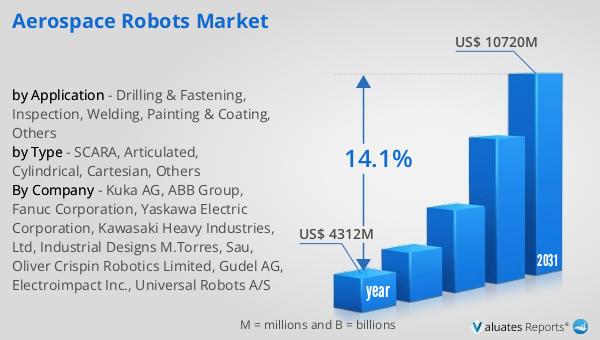

Global Aerospace Robots Market Outlook:

The global market for aerospace robots is experiencing significant growth, with its value estimated at $4,312 million in 2024. This market is projected to expand substantially, reaching a revised size of $10,720 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 14.1% during the forecast period. The increasing demand for aerospace robots is driven by the need for enhanced efficiency, precision, and safety in the aerospace industry. As the industry continues to evolve, the adoption of advanced robotic solutions is expected to rise, contributing to the market's expansion. The integration of robotics in aerospace manufacturing and maintenance processes not only boosts productivity but also reduces human error and enhances safety. This growing demand for aerospace robots is a testament to the industry's commitment to innovation and technological advancement. As the market continues to grow, it is expected to drive further developments and innovations in robotic technologies, contributing to the overall advancement of the aerospace industry. The projected growth of the Global Aerospace Robots Market highlights the increasing importance of robotics in the aerospace sector and its potential to transform the industry.

| Report Metric | Details |

| Report Name | Aerospace Robots Market |

| Accounted market size in year | US$ 4312 million |

| Forecasted market size in 2031 | US$ 10720 million |

| CAGR | 14.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kuka AG, ABB Group, Fanuc Corporation, Yaskawa Electric Corporation, Kawasaki Heavy Industries, Ltd, Industrial Designs M.Torres, Sau, Oliver Crispin Robotics Limited, Gudel AG, Electroimpact Inc., Universal Robots A/S |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |