What is Global Molecular Pump Market?

The Global Molecular Pump Market is a specialized segment within the broader vacuum pump industry, focusing on pumps that are essential for creating and maintaining high vacuum environments. These pumps are crucial in various high-tech applications, including semiconductor manufacturing, analytical instrumentation, and research and development in nanotechnology. Molecular pumps operate by using high-speed rotating blades or discs to impart momentum to gas molecules, effectively removing them from the vacuum chamber. This market is driven by the increasing demand for advanced manufacturing processes and the need for precise and contamination-free environments. As industries continue to innovate and push the boundaries of technology, the demand for molecular pumps is expected to grow. The market is characterized by a few key players who dominate the industry, offering a range of products that cater to different applications and requirements. These companies invest heavily in research and development to improve the efficiency and performance of their pumps, ensuring they meet the evolving needs of their customers. The Global Molecular Pump Market is poised for steady growth as technological advancements continue to drive demand for high-performance vacuum solutions.

Turbo Molecular Pump, Combined Molecular Pump, Molecular Drag Pump in the Global Molecular Pump Market:

Turbo Molecular Pumps, Combined Molecular Pumps, and Molecular Drag Pumps are integral components of the Global Molecular Pump Market, each serving distinct purposes and applications. Turbo Molecular Pumps (TMPs) are designed to achieve ultra-high vacuum levels by using rapidly spinning rotors to accelerate gas molecules, effectively removing them from the system. These pumps are highly efficient and are commonly used in applications requiring clean and oil-free vacuum environments, such as semiconductor fabrication and analytical instruments. TMPs are known for their high pumping speeds and ability to handle a wide range of gases, making them versatile and essential in high-tech industries. Combined Molecular Pumps, on the other hand, integrate multiple pumping mechanisms to enhance performance and efficiency. These pumps often combine the principles of turbo molecular and drag pumping, allowing them to operate effectively across a broader pressure range. This combination makes them suitable for applications where a single type of pump may not suffice, providing a more comprehensive solution for complex vacuum requirements. Combined Molecular Pumps are particularly useful in research and development settings, where flexibility and adaptability are crucial. Molecular Drag Pumps utilize the principle of gas molecule momentum transfer through a series of rotating discs or channels. These pumps are effective in achieving medium to high vacuum levels and are often used in conjunction with other types of pumps to enhance overall system performance. Molecular Drag Pumps are valued for their robustness and ability to handle corrosive or reactive gases, making them ideal for industrial applications where harsh conditions are common. Each type of molecular pump offers unique advantages, and the choice of pump depends on the specific requirements of the application, such as the desired vacuum level, gas composition, and operational environment. As the Global Molecular Pump Market continues to evolve, manufacturers are focusing on developing innovative solutions that combine the strengths of different pumping technologies to meet the diverse needs of their customers. This ongoing innovation is essential for maintaining competitiveness in a market that demands high performance, reliability, and efficiency.

Industrial Vacuum Processing, Nanotechnology Instruments, Analytical, Others in the Global Molecular Pump Market:

The Global Molecular Pump Market finds extensive usage across various sectors, including Industrial Vacuum Processing, Nanotechnology Instruments, Analytical applications, and others. In Industrial Vacuum Processing, molecular pumps are crucial for processes that require a clean and controlled environment, such as semiconductor manufacturing, thin-film deposition, and surface coating. These processes demand high vacuum levels to ensure the purity and quality of the final product, making molecular pumps indispensable. The ability of these pumps to maintain contamination-free conditions is vital for achieving the desired outcomes in industrial applications. In the realm of Nanotechnology Instruments, molecular pumps play a pivotal role in enabling the precise manipulation and analysis of materials at the nanoscale. These instruments require ultra-high vacuum conditions to prevent interference from air molecules, ensuring accurate measurements and observations. Molecular pumps provide the necessary vacuum levels to facilitate cutting-edge research and development in nanotechnology, driving innovation and discovery in this rapidly advancing field. Analytical applications, such as mass spectrometry and electron microscopy, also rely heavily on molecular pumps to achieve the high vacuum conditions needed for accurate analysis. These instruments are used in a wide range of industries, including pharmaceuticals, environmental science, and materials research, where precise and reliable data is essential. Molecular pumps ensure that these analytical tools operate at optimal performance, delivering the accuracy and sensitivity required for critical analyses. Beyond these specific areas, molecular pumps are used in various other applications that require high vacuum conditions, such as space simulation, particle accelerators, and vacuum metallurgy. The versatility and efficiency of molecular pumps make them suitable for a broad spectrum of uses, highlighting their importance in modern technology and industry. As the demand for advanced manufacturing processes and high-precision instruments continues to grow, the Global Molecular Pump Market is expected to expand, driven by the need for reliable and efficient vacuum solutions across diverse applications.

Global Molecular Pump Market Outlook:

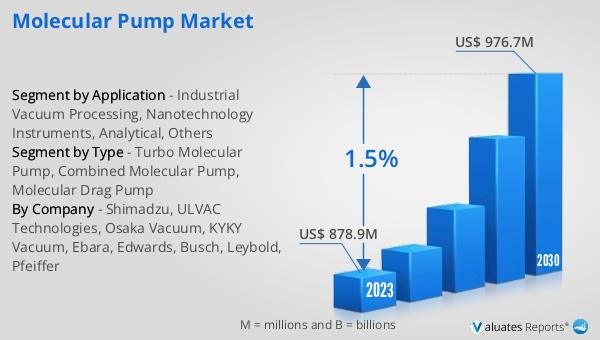

In 2024, the global market size of Molecular Pumps was valued at approximately US$ 905 million, with projections indicating it could reach around US$ 1003 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 1.5% during the forecast period from 2025 to 2031. The market is dominated by a few key players, with Pfeiffer, Shimadzu, Ebara, Edwards, and Leybold being the top five manufacturers. Together, these companies hold more than 50% of the market share, underscoring their significant influence and leadership in the industry. These manufacturers are known for their commitment to innovation and quality, continually developing new technologies and products to meet the evolving needs of their customers. Their dominance in the market is a testament to their ability to deliver high-performance, reliable, and efficient molecular pumps that cater to a wide range of applications. As the market continues to grow, these companies are likely to maintain their leading positions by focusing on research and development, expanding their product portfolios, and enhancing their global reach. The Global Molecular Pump Market is poised for steady growth, driven by the increasing demand for advanced vacuum solutions in various high-tech industries.

| Report Metric | Details |

| Report Name | Molecular Pump Market |

| Forecasted market size in 2031 | approximately US$ 1003 million |

| CAGR | 1.5% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Shimadzu, ULVAC Technologies, Osaka Vacuum, KYKY Vacuum, Ebara, Edwards, Busch, Leybold, Pfeiffer |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |