What is Global Insulating Radiation Heat Dissipation Coating Market?

The Global Insulating Radiation Heat Dissipation Coating Market is a specialized segment within the broader coatings industry, focusing on materials designed to manage heat through insulation and radiation. These coatings are engineered to dissipate heat efficiently, thereby protecting surfaces and components from thermal damage. They are particularly valuable in industries where temperature control is critical, such as electronics, automotive, and aerospace. The coatings work by reflecting and emitting thermal radiation, reducing the heat load on surfaces. This not only enhances the longevity and performance of components but also contributes to energy efficiency by minimizing the need for additional cooling systems. The market for these coatings is driven by the increasing demand for energy-efficient solutions and the growing awareness of the benefits of thermal management in various applications. As industries continue to innovate and seek sustainable solutions, the demand for insulating radiation heat dissipation coatings is expected to grow, offering significant opportunities for manufacturers and suppliers in this niche market. The coatings are available in various formulations to cater to different temperature ranges and application requirements, making them versatile solutions for diverse industrial needs.

Low Temperature Heat Dissipation Coating, Medium Temperature Heat Dissipation Coating, High Temperature Heat Dissipation Coating in the Global Insulating Radiation Heat Dissipation Coating Market:

Low Temperature Heat Dissipation Coatings are designed to manage heat in environments where temperatures do not exceed moderate levels. These coatings are typically used in applications where the operating temperatures range from ambient to around 200°C. They are formulated to provide effective thermal management without compromising the structural integrity of the substrate. In the Global Insulating Radiation Heat Dissipation Coating Market, low-temperature coatings are often used in consumer electronics, where devices need to remain cool to function efficiently and safely. These coatings help in dissipating heat generated by electronic components, thereby enhancing the performance and lifespan of devices. Medium Temperature Heat Dissipation Coatings are suitable for applications where temperatures range from 200°C to 500°C. These coatings are more robust than their low-temperature counterparts and are used in industries such as automotive and industrial machinery. In the automotive industry, these coatings are applied to engine components, exhaust systems, and other parts that are exposed to moderate heat levels. They help in maintaining optimal operating temperatures, reducing the risk of overheating, and improving fuel efficiency. In industrial machinery, medium temperature coatings protect equipment from thermal stress, ensuring reliable operation and reducing maintenance costs. High Temperature Heat Dissipation Coatings are designed for extreme environments where temperatures exceed 500°C. These coatings are used in industries such as aerospace, power generation, and metallurgy, where components are subjected to intense heat. In the aerospace industry, high-temperature coatings are applied to engine parts, turbine blades, and other critical components to protect them from thermal degradation. These coatings enhance the durability and performance of aerospace components, contributing to the safety and efficiency of aircraft. In power generation, high-temperature coatings are used in boilers, turbines, and other equipment to improve thermal efficiency and reduce energy consumption. In metallurgy, these coatings protect furnaces and other high-temperature equipment from heat-related damage, ensuring consistent performance and extending the lifespan of the equipment. The Global Insulating Radiation Heat Dissipation Coating Market offers a range of solutions to meet the diverse needs of industries operating in different temperature environments. By providing effective thermal management, these coatings contribute to improved performance, energy efficiency, and sustainability across various applications.

Semiconductor Industry, Automotive Industry, Others in the Global Insulating Radiation Heat Dissipation Coating Market:

The usage of Global Insulating Radiation Heat Dissipation Coating Market in the Semiconductor Industry is crucial for maintaining the performance and reliability of electronic components. In semiconductor manufacturing, these coatings are applied to wafers, chips, and other components to manage heat generated during operation. Effective thermal management is essential to prevent overheating, which can lead to component failure and reduced performance. By dissipating heat efficiently, these coatings help in maintaining optimal operating temperatures, ensuring the longevity and reliability of semiconductor devices. In the Automotive Industry, insulating radiation heat dissipation coatings are used to enhance the thermal management of various components, including engines, exhaust systems, and electronic control units. These coatings help in reducing the heat load on components, improving fuel efficiency, and reducing emissions. By maintaining optimal operating temperatures, these coatings contribute to the overall performance and efficiency of vehicles. In addition to improving fuel economy, they also enhance the durability and reliability of automotive components, reducing maintenance costs and extending the lifespan of vehicles. In other industries, such as aerospace, power generation, and industrial machinery, these coatings are used to protect components from thermal damage and improve energy efficiency. In the aerospace industry, for example, insulating radiation heat dissipation coatings are applied to engine parts, turbine blades, and other critical components to protect them from thermal degradation. These coatings enhance the durability and performance of aerospace components, contributing to the safety and efficiency of aircraft. In power generation, these coatings are used in boilers, turbines, and other equipment to improve thermal efficiency and reduce energy consumption. In industrial machinery, these coatings protect equipment from thermal stress, ensuring reliable operation and reducing maintenance costs. The versatility and effectiveness of insulating radiation heat dissipation coatings make them valuable solutions for a wide range of applications across different industries. By providing effective thermal management, these coatings contribute to improved performance, energy efficiency, and sustainability, making them an essential component of modern industrial processes.

Global Insulating Radiation Heat Dissipation Coating Market Outlook:

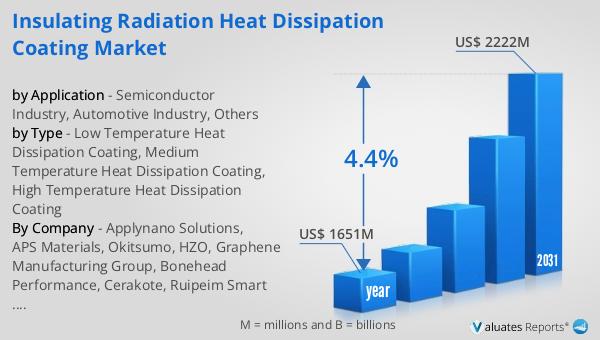

The global market for Insulating Radiation Heat Dissipation Coating was valued at $1,651 million in 2024 and is anticipated to grow to a revised size of $2,222 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.4% during the forecast period. This growth is driven by the increasing demand for energy-efficient solutions and the growing awareness of the benefits of thermal management in various applications. As industries continue to innovate and seek sustainable solutions, the demand for insulating radiation heat dissipation coatings is expected to grow, offering significant opportunities for manufacturers and suppliers in this niche market. The coatings are available in various formulations to cater to different temperature ranges and application requirements, making them versatile solutions for diverse industrial needs. The market's expansion is also supported by advancements in coating technologies and the development of new materials that offer improved performance and durability. As a result, the Global Insulating Radiation Heat Dissipation Coating Market is poised for significant growth in the coming years, driven by the increasing demand for energy-efficient solutions and the growing awareness of the benefits of thermal management in various applications.

| Report Metric | Details |

| Report Name | Insulating Radiation Heat Dissipation Coating Market |

| Accounted market size in year | US$ 1651 million |

| Forecasted market size in 2031 | US$ 2222 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Applynano Solutions, APS Materials, Okitsumo, HZO, Graphene Manufacturing Group, Bonehead Performance, Cerakote, Ruipeim Smart Coating, Surface Technology, Morion, 2D Carbon Tech, Carbonene |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |