What is Global Semi-Auto UV Curing Machine Market?

The Global Semi-Auto UV Curing Machine Market refers to the industry focused on the production and distribution of semi-automatic machines that utilize ultraviolet (UV) light to cure or harden materials. These machines are essential in various manufacturing processes where quick and efficient curing of coatings, adhesives, and inks is required. The semi-automatic nature of these machines means they require some level of human intervention, making them suitable for operations that need flexibility and precision. The market is driven by the increasing demand for UV curing technology due to its advantages, such as faster processing times, improved product quality, and reduced environmental impact compared to traditional curing methods. Industries such as electronics, automotive, and packaging are major consumers of these machines, as they seek to enhance their production efficiency and product durability. The market is characterized by technological advancements, with manufacturers continuously innovating to improve machine performance and energy efficiency. As industries increasingly adopt UV curing technology, the Global Semi-Auto UV Curing Machine Market is expected to grow, offering numerous opportunities for businesses involved in the production and supply of these machines.

Wavelength 365nm, Wavelength 385nm, Wavelength 395nm, Wavelength 405nm in the Global Semi-Auto UV Curing Machine Market:

In the Global Semi-Auto UV Curing Machine Market, different wavelengths of UV light play a crucial role in determining the effectiveness and efficiency of the curing process. Wavelengths such as 365nm, 385nm, 395nm, and 405nm are commonly used, each offering unique benefits and applications. The 365nm wavelength is often preferred for its deep penetration capabilities, making it ideal for curing thicker coatings and adhesives. This wavelength is particularly effective in applications where a strong bond is required, such as in the electronics industry for bonding components. On the other hand, the 385nm wavelength is known for its balance between penetration and surface curing, making it versatile for a wide range of applications. It is frequently used in the printing industry for curing inks and varnishes, providing a smooth and durable finish. The 395nm wavelength is favored for its efficiency in curing clear and pigmented coatings, offering a fast curing process without compromising on quality. This wavelength is commonly used in the automotive industry for coating applications, where speed and precision are critical. Lastly, the 405nm wavelength is recognized for its ability to cure materials with minimal heat generation, reducing the risk of thermal damage to sensitive substrates. This makes it suitable for applications in the medical and electronics industries, where maintaining the integrity of the substrate is essential. Each of these wavelengths offers distinct advantages, allowing manufacturers to choose the most appropriate option based on their specific curing requirements. As the Global Semi-Auto UV Curing Machine Market continues to evolve, the demand for machines capable of operating at these various wavelengths is expected to increase, driven by the need for more efficient and versatile curing solutions.

Wafer Packaging, Ceramic Cutting, Glass Processing, Others in the Global Semi-Auto UV Curing Machine Market:

The Global Semi-Auto UV Curing Machine Market finds extensive usage in various areas, including wafer packaging, ceramic cutting, glass processing, and other applications. In wafer packaging, these machines are crucial for ensuring the integrity and reliability of semiconductor devices. The UV curing process is used to harden protective coatings and adhesives, providing a robust barrier against environmental factors such as moisture and dust. This is essential for maintaining the performance and longevity of semiconductor components, which are integral to electronic devices. In ceramic cutting, UV curing machines are employed to cure adhesives used in bonding ceramic pieces. The precision and speed offered by UV curing technology enhance the efficiency of the cutting process, resulting in cleaner cuts and reduced material wastage. This is particularly important in industries such as construction and manufacturing, where ceramic materials are widely used. Glass processing is another area where the Global Semi-Auto UV Curing Machine Market plays a significant role. UV curing is used to bond glass components, providing a strong and durable connection that can withstand various environmental conditions. This is essential in applications such as automotive glass and architectural glazing, where safety and durability are paramount. Additionally, the market serves other applications, including the curing of coatings and inks in the printing industry, where UV curing technology is valued for its ability to produce high-quality, durable prints with minimal environmental impact. The versatility and efficiency of semi-auto UV curing machines make them indispensable in these areas, driving their adoption across various industries. As the demand for high-performance materials and components continues to grow, the Global Semi-Auto UV Curing Machine Market is expected to expand, offering new opportunities for innovation and growth.

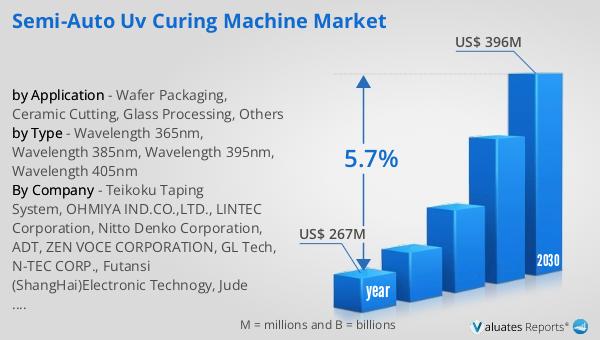

Global Semi-Auto UV Curing Machine Market Outlook:

The global market for Semi-Auto UV Curing Machines was valued at $267 million in 2023, and it is anticipated to grow to a revised size of $396 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.7% over the forecast period. This growth trajectory underscores the increasing demand for UV curing technology across various industries. The market's expansion is driven by the need for efficient and environmentally friendly curing solutions, as industries seek to enhance their production processes and product quality. The semi-automatic nature of these machines offers a balance between automation and human intervention, making them suitable for applications that require precision and flexibility. As industries such as electronics, automotive, and packaging continue to adopt UV curing technology, the market is poised for significant growth. The projected increase in market size highlights the opportunities available for manufacturers and suppliers of semi-auto UV curing machines, as they strive to meet the evolving needs of their customers. With technological advancements and innovations in UV curing technology, the market is expected to witness continued growth, offering numerous opportunities for businesses involved in this sector.

| Report Metric | Details |

| Report Name | Semi-Auto UV Curing Machine Market |

| Accounted market size in year | US$ 267 million |

| Forecasted market size in 2030 | US$ 396 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Teikoku Taping System, OHMIYA IND.CO.,LTD., LINTEC Corporation, Nitto Denko Corporation, ADT, ZEN VOCE CORPORATION, GL Tech, N-TEC CORP., Futansi (ShangHai)Electronic Technogy, Jude Weiye Electronic, Cepheus Technology, Brightek |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |