What is Global Semi-Auto UVLED Curing Machine Market?

The Global Semi-Auto UVLED Curing Machine Market is a specialized segment within the broader UV curing technology industry. These machines utilize ultraviolet light-emitting diodes (UVLEDs) to cure or dry inks, coatings, adhesives, and other materials. Unlike traditional curing methods that rely on mercury lamps, UVLED curing machines offer several advantages, including energy efficiency, longer lifespan, and reduced environmental impact. The "semi-auto" aspect refers to the level of automation in the machine's operation, which combines manual and automated processes to enhance flexibility and efficiency. This market is driven by the increasing demand for high-performance curing solutions across various industries such as electronics, automotive, and packaging. The machines are particularly valued for their precision and ability to handle delicate materials without causing thermal damage. As industries continue to seek sustainable and efficient production methods, the adoption of semi-auto UVLED curing machines is expected to grow, offering a promising outlook for manufacturers and stakeholders in this market. The technology's adaptability to different wavelengths further enhances its application range, making it a versatile choice for modern manufacturing needs.

Wavelength 365nm, Wavelength 385nm, Wavelength 395nm, Wavelength 405nm in the Global Semi-Auto UVLED Curing Machine Market:

In the Global Semi-Auto UVLED Curing Machine Market, different wavelengths play a crucial role in determining the effectiveness and suitability of the curing process for various applications. The wavelengths 365nm, 385nm, 395nm, and 405nm are particularly significant, each offering unique benefits and applications. The 365nm wavelength is often used for applications requiring deep penetration and strong adhesion, such as in the curing of thick coatings or adhesives. This wavelength is highly effective in initiating photochemical reactions, making it ideal for industrial applications where robust curing is essential. The 385nm wavelength, on the other hand, is commonly used in applications where a balance between penetration and surface curing is needed. It is often employed in the electronics industry for curing coatings on circuit boards and other components, providing a reliable cure without excessive heat generation. The 395nm wavelength is favored for its efficiency in curing inks and coatings that require a quick surface cure. This wavelength is particularly useful in the printing industry, where rapid curing is essential to maintain production speed and quality. It offers a good balance between energy consumption and curing speed, making it a cost-effective choice for high-volume applications. Lastly, the 405nm wavelength is known for its ability to cure materials that are sensitive to shorter wavelengths. It is often used in applications where minimal heat generation is crucial, such as in the curing of heat-sensitive substrates or delicate materials. This wavelength is also popular in the medical and dental industries, where precision and safety are paramount. Overall, the choice of wavelength in the Global Semi-Auto UVLED Curing Machine Market is dictated by the specific requirements of the application, with each wavelength offering distinct advantages that cater to different industrial needs. The versatility of these machines in accommodating various wavelengths makes them an attractive option for manufacturers seeking efficient and adaptable curing solutions. As industries continue to evolve and demand more specialized curing processes, the ability to tailor the wavelength to specific applications will remain a key factor in the growth and development of the UVLED curing machine market.

Wafer Packaging, Ceramic Cutting, Glass Processing, Others in the Global Semi-Auto UVLED Curing Machine Market:

The Global Semi-Auto UVLED Curing Machine Market finds extensive usage across various industries, including wafer packaging, ceramic cutting, glass processing, and others. In wafer packaging, these machines are instrumental in the semiconductor industry, where precision and reliability are paramount. The UVLED curing process ensures that adhesives and coatings used in wafer packaging are cured uniformly and efficiently, enhancing the durability and performance of the final product. The ability to control the curing process with precision reduces the risk of defects and improves the overall quality of semiconductor devices. In ceramic cutting, UVLED curing machines are used to cure coatings and adhesives that enhance the cutting process. The machines provide a controlled curing environment that ensures the coatings adhere properly, reducing the risk of chipping or cracking during cutting. This results in smoother cuts and improved product quality, making the process more efficient and cost-effective. In glass processing, UVLED curing machines are used to cure coatings and adhesives that are applied to glass surfaces. The machines offer a precise and controlled curing process that ensures the coatings adhere properly, enhancing the durability and appearance of the glass. This is particularly important in industries such as automotive and construction, where the quality and performance of glass products are critical. The ability to cure coatings quickly and efficiently also reduces production time and costs, making UVLED curing machines an attractive option for glass manufacturers. Beyond these specific applications, the Global Semi-Auto UVLED Curing Machine Market also finds usage in a variety of other industries. The machines are used in the production of electronics, where they cure coatings and adhesives on circuit boards and other components. They are also used in the printing industry, where they cure inks and coatings on various substrates, ensuring high-quality prints with minimal environmental impact. The versatility and efficiency of UVLED curing machines make them a valuable tool for manufacturers seeking to improve their production processes and reduce their environmental footprint. As industries continue to evolve and demand more efficient and sustainable production methods, the usage of semi-auto UVLED curing machines is expected to grow, offering a promising outlook for this market.

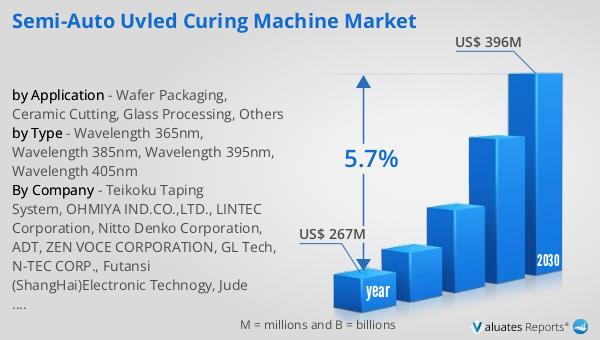

Global Semi-Auto UVLED Curing Machine Market Outlook:

In 2023, the global market for Semi-Auto UVLED Curing Machines was valued at approximately $267 million. This market is anticipated to expand significantly, reaching an estimated value of $396 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 5.7% over the forecast period. The increasing demand for efficient and environmentally friendly curing solutions across various industries is a key driver of this market growth. Semi-Auto UVLED Curing Machines offer numerous advantages, including energy efficiency, reduced environmental impact, and the ability to handle delicate materials with precision. These benefits are particularly appealing to industries such as electronics, automotive, and packaging, where high-performance curing solutions are essential. As manufacturers continue to seek sustainable and efficient production methods, the adoption of semi-auto UVLED curing machines is expected to increase, contributing to the market's growth. The ability of these machines to accommodate different wavelengths further enhances their application range, making them a versatile choice for modern manufacturing needs. Overall, the Global Semi-Auto UVLED Curing Machine Market is poised for significant growth, driven by the increasing demand for advanced curing solutions and the ongoing shift towards more sustainable production practices.

| Report Metric | Details |

| Report Name | Semi-Auto UVLED Curing Machine Market |

| Accounted market size in year | US$ 267 million |

| Forecasted market size in 2030 | US$ 396 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Teikoku Taping System, OHMIYA IND.CO.,LTD., LINTEC Corporation, Nitto Denko Corporation, ADT, ZEN VOCE CORPORATION, GL Tech, N-TEC CORP., Futansi (ShangHai)Electronic Technogy, Jude Weiye Electronic, Cepheus Technology, Brightek |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |