What is Global X-ray Food & Pharmaceutical Inspection System Market?

The Global X-ray Food & Pharmaceutical Inspection System Market is a specialized segment within the broader inspection systems industry, focusing on the use of X-ray technology to ensure the safety and quality of food and pharmaceutical products. These systems are designed to detect contaminants, such as metal, glass, stone, and other foreign materials, that may be present in packaged or bulk products. The technology is highly valued for its ability to provide non-destructive testing, meaning it can inspect products without damaging them, which is crucial for maintaining product integrity. In the food industry, X-ray inspection systems help in identifying physical contaminants and ensuring compliance with safety standards, thereby protecting consumers and brands alike. In the pharmaceutical sector, these systems are used to verify the integrity of tablets, capsules, and other products, ensuring they are free from contaminants and defects. The market for these systems is driven by increasing regulatory requirements, consumer demand for safe products, and the need for manufacturers to maintain high-quality standards. As industries continue to prioritize safety and quality, the demand for advanced inspection technologies like X-ray systems is expected to grow, making this market an essential component of the global food and pharmaceutical supply chains.

Packaged Product Inspection Equipment, Bulk Product Inspection Equipment in the Global X-ray Food & Pharmaceutical Inspection System Market:

Packaged Product Inspection Equipment and Bulk Product Inspection Equipment are two critical components of the Global X-ray Food & Pharmaceutical Inspection System Market. Packaged Product Inspection Equipment is specifically designed to inspect products that are already packaged, such as boxed, bagged, or bottled goods. These systems are crucial in ensuring that the final product reaching the consumer is free from any physical contaminants. They work by scanning the packaged goods and using advanced algorithms to detect any anomalies that might indicate the presence of foreign materials. This type of equipment is widely used in both the food and pharmaceutical industries, where the integrity of the packaging and the safety of the contents are paramount. For instance, in the food industry, packaged product inspection equipment can detect contaminants like metal shards or glass pieces that might have accidentally entered during the packaging process. In the pharmaceutical industry, these systems ensure that tablets or capsules are correctly filled and free from defects or contaminants before they are sealed and shipped. On the other hand, Bulk Product Inspection Equipment is used to inspect products in bulk form before they are packaged. This type of equipment is essential for industries that deal with raw materials or products that are processed in large quantities. In the food industry, bulk product inspection equipment is used to scan items like grains, nuts, or meat products to detect any foreign objects before they are processed further or packaged. This ensures that any contaminants are removed early in the production process, reducing the risk of them ending up in the final product. In the pharmaceutical industry, bulk inspection equipment is used to inspect raw materials like powders or granules to ensure they meet the required safety and quality standards before they are used in the production of medicines. Both types of inspection equipment play a vital role in maintaining the safety and quality of products in the food and pharmaceutical industries. They help manufacturers comply with stringent regulatory requirements and meet consumer expectations for safe and high-quality products. The choice between packaged and bulk inspection equipment depends on the specific needs of the manufacturer and the stage of the production process where inspection is most critical. As technology advances, these systems are becoming more sophisticated, with features like real-time data analysis, automated reporting, and integration with other quality control systems. This not only enhances their efficiency but also provides manufacturers with valuable insights into their production processes, helping them to identify and address potential issues before they become major problems. Overall, the Global X-ray Food & Pharmaceutical Inspection System Market is a dynamic and evolving sector that plays a crucial role in ensuring the safety and quality of products that consumers rely on every day.

Food, Pharmaceutical in the Global X-ray Food & Pharmaceutical Inspection System Market:

The usage of Global X-ray Food & Pharmaceutical Inspection System Market in the food and pharmaceutical sectors is extensive and multifaceted. In the food industry, X-ray inspection systems are employed at various stages of the production process to ensure that the final product is safe for consumption. These systems are capable of detecting a wide range of contaminants, including metal, glass, stone, and even some types of plastic, which might be present in food products due to accidental contamination during processing or packaging. By identifying and removing these contaminants, X-ray inspection systems help manufacturers comply with food safety regulations and protect consumers from potential health hazards. Additionally, these systems can also be used to check the integrity of packaging, ensuring that products are sealed correctly and free from defects that could compromise their quality or safety. In the pharmaceutical industry, X-ray inspection systems are used to ensure the safety and quality of medicines and other healthcare products. These systems are capable of inspecting tablets, capsules, and other pharmaceutical products to detect any foreign materials or defects that might affect their efficacy or safety. For example, X-ray inspection systems can identify broken tablets, missing components, or incorrect fill levels in blister packs, ensuring that only products that meet the required quality standards are released to the market. This is particularly important in the pharmaceutical industry, where even minor defects can have serious implications for patient safety and product efficacy. Moreover, X-ray inspection systems can also be used to verify the integrity of packaging, ensuring that products are protected from contamination and tampering. The use of X-ray inspection systems in both the food and pharmaceutical industries is driven by the need to comply with stringent regulatory requirements and meet consumer expectations for safe and high-quality products. These systems provide manufacturers with a reliable and efficient way to detect and remove contaminants, ensuring that their products meet the highest safety and quality standards. Furthermore, the data collected by these systems can be used to improve production processes, identify potential issues, and implement corrective actions, helping manufacturers to maintain their competitive edge in the market. As technology continues to advance, X-ray inspection systems are becoming more sophisticated, with features like real-time data analysis, automated reporting, and integration with other quality control systems. This not only enhances their efficiency but also provides manufacturers with valuable insights into their production processes, helping them to identify and address potential issues before they become major problems. Overall, the Global X-ray Food & Pharmaceutical Inspection System Market plays a crucial role in ensuring the safety and quality of products that consumers rely on every day.

Global X-ray Food & Pharmaceutical Inspection System Market Outlook:

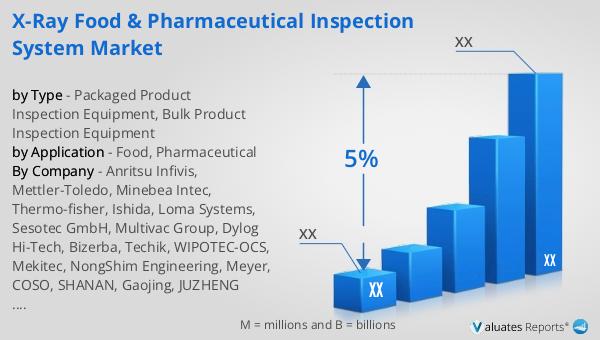

In 2022, the global pharmaceutical market reached a valuation of 1,475 billion USD, demonstrating a steady growth trajectory with a compound annual growth rate (CAGR) of 5% projected over the next six years. This growth reflects the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, rising prevalence of chronic diseases, and advancements in medical technology. In comparison, the chemical drug market has also shown significant growth, expanding from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This increase highlights the ongoing importance of chemical drugs in the global healthcare landscape, despite the growing interest in biologics and other innovative therapies. The expansion of both the pharmaceutical and chemical drug markets underscores the critical role of inspection systems in ensuring the safety and quality of these products. As the demand for pharmaceutical products continues to rise, manufacturers are under increasing pressure to comply with stringent regulatory requirements and meet consumer expectations for safe and effective medicines. This has led to a growing reliance on advanced inspection technologies, such as X-ray systems, to detect and remove contaminants, verify product integrity, and ensure compliance with industry standards. As a result, the Global X-ray Food & Pharmaceutical Inspection System Market is poised to play an increasingly important role in supporting the growth and development of the pharmaceutical industry.

| Report Metric | Details |

| Report Name | X-ray Food & Pharmaceutical Inspection System Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Anritsu Infivis, Mettler-Toledo, Minebea Intec, Thermo-fisher, Ishida, Loma Systems, Sesotec GmbH, Multivac Group, Dylog Hi-Tech, Bizerba, Techik, WIPOTEC-OCS, Mekitec, NongShim Engineering, Meyer, COSO, SHANAN, Gaojing, JUZHENG Electronic and Technology, Easyweigh |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |