What is Global Electron Beam Physical Vapor Deposition (EBPVD) Coating Market?

The Global Electron Beam Physical Vapor Deposition (EBPVD) Coating Market is a specialized segment within the broader coatings industry, focusing on the use of electron beam technology to deposit thin films onto various substrates. This process involves the evaporation of a material using an electron beam in a high-vacuum environment, allowing the vaporized material to condense and form a coating on the target surface. EBPVD coatings are known for their high purity, excellent adhesion, and uniform thickness, making them ideal for applications requiring precision and durability. The market for these coatings is driven by their use in industries such as aerospace, automotive, electronics, and energy, where they provide critical benefits like thermal protection, corrosion resistance, and enhanced surface properties. As industries continue to demand advanced materials with superior performance characteristics, the EBPVD coating market is expected to grow, driven by technological advancements and increasing applications across various sectors. The market's growth is also supported by the rising need for energy-efficient solutions and the development of new materials that can withstand extreme conditions. Overall, the Global EBPVD Coating Market represents a dynamic and evolving field with significant potential for innovation and expansion.

Thermal Barrier Coatings, Anticorrosive Coating, Others in the Global Electron Beam Physical Vapor Deposition (EBPVD) Coating Market:

Thermal Barrier Coatings (TBCs) are a critical component of the Global Electron Beam Physical Vapor Deposition (EBPVD) Coating Market. These coatings are designed to protect components from extreme temperatures, primarily in high-temperature environments such as gas turbines and jet engines. TBCs are typically composed of ceramic materials that provide excellent thermal insulation, reducing the heat transfer to the underlying substrate. This not only enhances the efficiency of the engine by allowing it to operate at higher temperatures but also extends the lifespan of the components by preventing thermal degradation. The EBPVD process is particularly suited for applying TBCs due to its ability to produce coatings with precise thickness control and excellent adhesion, ensuring optimal performance in demanding applications. Anticorrosive coatings, another significant segment within the EBPVD Coating Market, are designed to protect surfaces from corrosion, which can lead to material degradation and failure. These coatings are essential in industries such as marine, oil and gas, and infrastructure, where exposure to harsh environmental conditions is common. EBPVD coatings offer superior corrosion resistance due to their dense and uniform structure, which acts as a barrier against corrosive agents. The ability to tailor the composition of the coating to specific environmental conditions further enhances their protective capabilities. Other applications of EBPVD coatings include wear-resistant coatings, optical coatings, and decorative coatings. Wear-resistant coatings are used to enhance the durability and lifespan of components subjected to friction and abrasion, such as cutting tools and mechanical parts. Optical coatings, on the other hand, are used to modify the reflective and transmissive properties of surfaces, making them essential in the production of lenses, mirrors, and other optical devices. Decorative coatings are used to enhance the aesthetic appeal of products, providing a visually appealing finish that is also durable and resistant to wear. The versatility of the EBPVD process allows for the deposition of a wide range of materials, enabling the development of coatings with tailored properties to meet specific application requirements. As industries continue to seek advanced solutions for improving performance and extending the lifespan of their products, the demand for EBPVD coatings is expected to grow, driven by their unique advantages and broad range of applications.

Semiconductor, Aerospace, Others in the Global Electron Beam Physical Vapor Deposition (EBPVD) Coating Market:

The Global Electron Beam Physical Vapor Deposition (EBPVD) Coating Market finds extensive usage in various sectors, including semiconductors, aerospace, and others, due to its ability to produce high-quality coatings with precise control over thickness and composition. In the semiconductor industry, EBPVD coatings are used to deposit thin films of materials such as metals, dielectrics, and semiconductors onto wafers. These coatings are essential for the fabrication of integrated circuits and other electronic components, where they serve functions such as electrical conductivity, insulation, and protection. The ability to deposit ultra-thin, uniform coatings with excellent adhesion is critical in this industry, where even minor imperfections can lead to device failure. The aerospace industry is another major user of EBPVD coatings, particularly for thermal barrier coatings (TBCs) and wear-resistant coatings. TBCs are used to protect engine components from the extreme temperatures encountered during operation, enhancing efficiency and extending component life. Wear-resistant coatings are applied to components such as turbine blades and landing gear to reduce friction and wear, improving performance and reliability. The precision and quality of EBPVD coatings make them ideal for these demanding applications, where performance and safety are paramount. Beyond semiconductors and aerospace, EBPVD coatings are used in a variety of other industries, including automotive, medical, and energy. In the automotive industry, these coatings are used to enhance the performance and durability of engine components, reducing wear and improving fuel efficiency. In the medical field, EBPVD coatings are used to improve the biocompatibility and wear resistance of implants and surgical instruments, ensuring patient safety and extending the lifespan of medical devices. In the energy sector, EBPVD coatings are used to protect components in power generation and oil and gas applications from corrosion and wear, enhancing efficiency and reducing maintenance costs. The versatility and performance advantages of EBPVD coatings make them a valuable tool across a wide range of industries, driving demand and innovation in the market. As industries continue to seek advanced materials and solutions to meet their evolving needs, the Global EBPVD Coating Market is poised for continued growth and development.

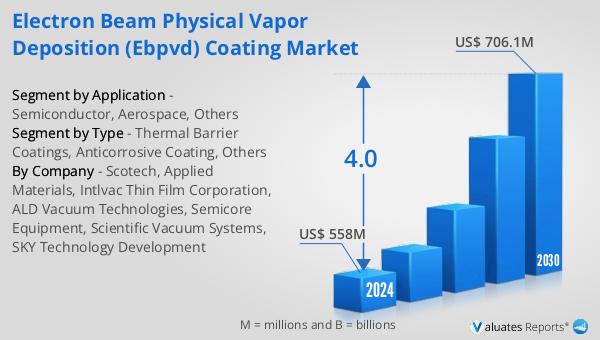

Global Electron Beam Physical Vapor Deposition (EBPVD) Coating Market Outlook:

The outlook for the Global Electron Beam Physical Vapor Deposition (EBPVD) Coating Market indicates a promising growth trajectory. The market is anticipated to expand from a valuation of $558 million in 2024 to approximately $706.1 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 4.0% over the forecast period. This growth is driven by the increasing demand for high-performance coatings in various industries, including aerospace, which is the largest segment within the EBPVD Coating Market. In 2019, the aerospace sector accounted for nearly 33% of the market share, underscoring its significance in driving market expansion. The aerospace industry's reliance on EBPVD coatings for applications such as thermal barrier coatings and wear-resistant coatings highlights the critical role these coatings play in enhancing the performance and durability of aerospace components. As the industry continues to evolve and demand more advanced materials, the EBPVD Coating Market is expected to benefit from ongoing technological advancements and the development of new applications. The market's growth is also supported by the increasing focus on energy efficiency and sustainability, as EBPVD coatings offer solutions that enhance performance while reducing environmental impact. Overall, the Global EBPVD Coating Market presents significant opportunities for growth and innovation, driven by the diverse range of applications and the continuous advancement of coating technologies.

| Report Metric | Details |

| Report Name | Electron Beam Physical Vapor Deposition (EBPVD) Coating Market |

| Accounted market size in 2024 | US$ 558 million |

| Forecasted market size in 2030 | US$ 706.1 million |

| CAGR | 4.0 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Scotech, Applied Materials, Intlvac Thin Film Corporation, ALD Vacuum Technologies, Semicore Equipment, Scientific Vacuum Systems, SKY Technology Development |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |