What is Alkali Resistant (AR) Glass Fiber - Global Market?

Alkali Resistant (AR) Glass Fiber is a specialized type of glass fiber designed to withstand alkaline environments, which are common in construction and other industrial applications. Unlike regular glass fibers, AR glass fibers are manufactured with a high zirconia content, making them resistant to the corrosive effects of alkaline substances such as cement and lime. This unique property makes AR glass fibers an essential component in reinforcing concrete and other building materials, enhancing their durability and longevity. The global market for AR glass fiber is driven by the increasing demand for durable construction materials that can withstand harsh environmental conditions. As infrastructure projects continue to expand worldwide, the need for materials that offer both strength and resistance to chemical degradation becomes more critical. AR glass fibers are also used in various other applications, including the automotive and aerospace industries, where their lightweight and high-strength properties are highly valued. The market is characterized by a growing interest in sustainable and long-lasting building solutions, which AR glass fibers can provide. As a result, manufacturers are continually innovating to improve the performance and cost-effectiveness of these fibers, further fueling their adoption across different sectors.

1/2 Inch, 3/4 Inch, Others in the Alkali Resistant (AR) Glass Fiber - Global Market:

In the global market for Alkali Resistant (AR) Glass Fiber, different sizes such as 1/2 inch, 3/4 inch, and others play a significant role in catering to diverse application needs. The 1/2 inch AR glass fiber is commonly used in applications where fine detailing and precision are required. Its smaller size allows for better integration into intricate designs, making it ideal for use in decorative concrete elements, thin-walled structures, and other applications where aesthetics and detail are paramount. This size is also preferred in applications where the fiber needs to be mixed with other materials to create a composite that offers enhanced strength and durability without adding significant weight. On the other hand, the 3/4 inch AR glass fiber is typically used in applications that require more substantial reinforcement. Its larger size provides greater tensile strength, making it suitable for use in structural components such as beams, columns, and slabs. This size is particularly beneficial in construction projects where load-bearing capacity is a critical consideration. The larger fibers can bridge cracks and distribute loads more effectively, contributing to the overall stability and longevity of the structure. Additionally, the 3/4 inch size is often used in precast concrete products, where its reinforcing properties help to improve the performance and durability of the final product. Beyond these standard sizes, the market also offers other sizes of AR glass fibers to meet specific application requirements. These can range from very fine fibers used in specialized applications such as filtration and insulation, to larger fibers used in heavy-duty industrial applications. The availability of different sizes allows manufacturers and end-users to select the most appropriate fiber for their specific needs, ensuring optimal performance and cost-effectiveness. The choice of fiber size is often influenced by factors such as the type of application, the desired properties of the final product, and the specific environmental conditions in which the product will be used. As the global market for AR glass fiber continues to grow, the demand for different sizes is expected to increase, driven by the expanding range of applications and the need for customized solutions. Manufacturers are continually developing new sizes and formulations to meet the evolving needs of the market, ensuring that AR glass fibers remain a versatile and valuable material in a wide range of industries.

Building Industry, Agricultural Facility, Garnish, Others in the Alkali Resistant (AR) Glass Fiber - Global Market:

Alkali Resistant (AR) Glass Fiber finds extensive usage in various sectors, including the building industry, agricultural facilities, garnish applications, and others. In the building industry, AR glass fibers are primarily used to reinforce concrete and other construction materials. Their resistance to alkaline environments makes them ideal for use in structures exposed to harsh weather conditions and chemical agents. By incorporating AR glass fibers into concrete, builders can enhance the material's tensile strength, reduce cracking, and improve its overall durability. This makes AR glass fibers a popular choice for infrastructure projects such as bridges, tunnels, and high-rise buildings, where long-term performance and safety are paramount. In agricultural facilities, AR glass fibers are used to reinforce structures that are frequently exposed to moisture and chemicals, such as greenhouses, storage facilities, and animal shelters. The fibers help to prevent degradation and extend the lifespan of these structures, reducing maintenance costs and ensuring a safe environment for agricultural activities. Additionally, AR glass fibers can be used in the production of agricultural equipment and machinery, where their lightweight and high-strength properties contribute to improved performance and efficiency. In garnish applications, AR glass fibers are used to create decorative elements that require both aesthetic appeal and structural integrity. These fibers can be incorporated into a variety of materials, including concrete, plaster, and composites, to produce intricate designs and patterns that enhance the visual appeal of buildings and other structures. The use of AR glass fibers in garnish applications allows for greater design flexibility and creativity, enabling architects and designers to achieve unique and innovative results. Beyond these specific areas, AR glass fibers are also used in a wide range of other applications, including automotive and aerospace components, marine structures, and industrial equipment. Their versatility and performance characteristics make them a valuable material in any application where strength, durability, and resistance to chemical degradation are important considerations. As the global market for AR glass fiber continues to expand, the range of applications is expected to grow, driven by ongoing innovation and the development of new products and technologies.

Alkali Resistant (AR) Glass Fiber - Global Market Outlook:

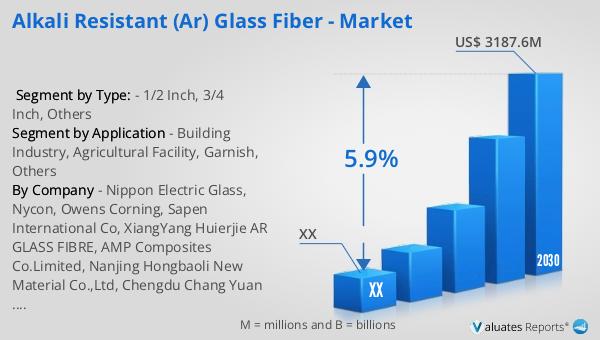

The global market for Alkali Resistant (AR) Glass Fiber was valued at approximately $2,145.9 million in 2023. Looking ahead, the market is projected to grow significantly, reaching an estimated size of $3,187.6 million by 2030. This growth represents a compound annual growth rate (CAGR) of 5.9% over the forecast period from 2024 to 2030. This upward trend is indicative of the increasing demand for AR glass fibers across various industries, driven by their unique properties and wide range of applications. The North American market, in particular, is expected to play a significant role in this growth, as the region continues to invest in infrastructure development and sustainable building solutions. The rising awareness of the benefits of AR glass fibers, such as their resistance to alkaline environments and ability to enhance the durability of construction materials, is contributing to their growing adoption. As industries continue to seek materials that offer both performance and sustainability, AR glass fibers are well-positioned to meet these demands, further fueling their market growth. The ongoing innovation and development of new products and technologies are also expected to drive the market forward, as manufacturers strive to improve the performance and cost-effectiveness of AR glass fibers.

| Report Metric | Details |

| Report Name | Alkali Resistant (AR) Glass Fiber - Market |

| Forecasted market size in 2030 | US$ 3187.6 million |

| CAGR | 5.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Nippon Electric Glass, Nycon, Owens Corning, Sapen International Co, XiangYang Huierjie AR GLASS FIBRE, AMP Composites Co.Limited, Nanjing Hongbaoli New Material Co.,Ltd, Chengdu Chang Yuan Shun Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |