What is Automatic Labeler - Global Market?

Automatic labelers are essential machines in the global market, designed to apply labels to products efficiently and accurately. These machines are widely used across various industries due to their ability to enhance productivity and ensure consistency in labeling. Automatic labelers come in different types, including pressure-sensitive, cold-glue, hot-melt glue, and sleeve labelers, each catering to specific labeling needs. The global market for automatic labelers is driven by the increasing demand for packaged goods, the need for efficient production processes, and stringent labeling regulations across industries. As businesses strive to improve their operational efficiency, automatic labelers offer a solution by reducing manual labor and minimizing errors in the labeling process. The market is characterized by technological advancements, such as the integration of digital printing and automation technologies, which further enhance the capabilities of these machines. With the growing emphasis on product differentiation and branding, automatic labelers play a crucial role in helping companies achieve their marketing objectives by ensuring that labels are applied accurately and consistently. As a result, the global market for automatic labelers is expected to continue growing, driven by the increasing demand for efficient and reliable labeling solutions across various industries.

Cold-glue, Hot-melt Glue in the Automatic Labeler - Global Market:

Cold-glue and hot-melt glue are two popular adhesive technologies used in automatic labelers, each offering distinct advantages and applications in the global market. Cold-glue labelers use water-based adhesives that are applied at room temperature. These adhesives are known for their strong bonding capabilities and are ideal for labeling applications where heat-sensitive materials are involved. Cold-glue labelers are commonly used in industries such as food and beverage, where labels need to withstand varying temperatures and moisture levels. The adhesive's water-based nature makes it an environmentally friendly option, as it reduces the emission of volatile organic compounds (VOCs) during the labeling process. Additionally, cold-glue labelers are cost-effective, as the adhesives are generally less expensive than their hot-melt counterparts. On the other hand, hot-melt glue labelers use thermoplastic adhesives that are applied in a molten state. These adhesives solidify quickly upon cooling, providing a strong and durable bond. Hot-melt glue labelers are favored in industries where high-speed labeling is required, such as in the packaging of consumer goods. The quick-setting nature of hot-melt adhesives allows for rapid production cycles, making them suitable for large-scale operations. Moreover, hot-melt adhesives offer excellent adhesion to a wide range of substrates, including plastics, metals, and glass, making them versatile for various labeling applications. However, the use of hot-melt adhesives requires careful temperature control to prevent degradation of the adhesive properties and ensure consistent label application. Despite the differences in adhesive technology, both cold-glue and hot-melt glue labelers are integral to the automatic labeler market, providing reliable and efficient labeling solutions for diverse industries. As the demand for packaged goods continues to rise, the need for advanced labeling technologies that offer both performance and sustainability is expected to drive the growth of the cold-glue and hot-melt glue segments in the global automatic labeler market.

Food and Beverage, Industrial, Medical, Cosmetics, Other in the Automatic Labeler - Global Market:

Automatic labelers are extensively used in various industries, including food and beverage, industrial, medical, cosmetics, and others, due to their ability to enhance efficiency and accuracy in the labeling process. In the food and beverage industry, automatic labelers are crucial for ensuring that products are labeled correctly and consistently, which is essential for compliance with regulatory standards and for maintaining brand integrity. These machines can handle a wide range of packaging types, from bottles and cans to cartons and pouches, making them versatile for different product lines. In the industrial sector, automatic labelers are used to label products such as chemicals, automotive parts, and electronics. The ability to apply labels quickly and accurately is vital in this sector, where production volumes are high, and precision is critical. In the medical industry, automatic labelers play a key role in labeling pharmaceuticals, medical devices, and laboratory samples. The accuracy and reliability of these machines are paramount, as incorrect labeling can have serious consequences for patient safety and regulatory compliance. In the cosmetics industry, automatic labelers help brands achieve a polished and professional appearance for their products, which is essential for attracting consumers in a competitive market. These machines can handle a variety of packaging shapes and sizes, from tubes and jars to bottles and compacts, ensuring that labels are applied seamlessly. Beyond these industries, automatic labelers are also used in sectors such as logistics, where they help streamline the labeling of packages and shipments, and in the personal care industry, where they ensure that products are labeled attractively and accurately. Overall, the versatility and efficiency of automatic labelers make them indispensable tools across a wide range of industries, helping businesses improve their operational efficiency and maintain high standards of quality and compliance.

Automatic Labeler - Global Market Outlook:

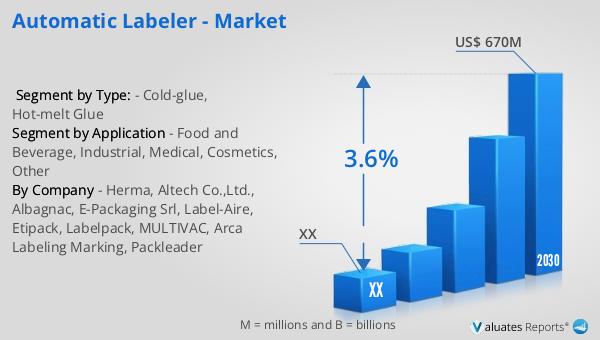

The global market for automatic labelers was valued at approximately US$ 520 million in 2023, with projections indicating a growth to around US$ 670 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.6% during the forecast period from 2024 to 2030. The market is characterized by the presence of several key players, including Videojet, Markem-Imaje, Cotao, and Domino, among others. These companies are at the forefront of innovation in the automatic labeler industry, offering advanced solutions that cater to the diverse needs of businesses across various sectors. The top five manufacturers in the global market hold a significant share, accounting for approximately 50% of the market. This concentration of market share among leading players highlights the competitive nature of the industry and the importance of technological advancements in maintaining a competitive edge. As businesses continue to seek efficient and reliable labeling solutions, the demand for automatic labelers is expected to grow, driven by factors such as the increasing need for product differentiation, compliance with labeling regulations, and the desire to enhance operational efficiency. The market outlook for automatic labelers remains positive, with opportunities for growth and innovation as companies strive to meet the evolving needs of their customers.

| Report Metric | Details |

| Report Name | Automatic Labeler - Market |

| Forecasted market size in 2030 | US$ 670 million |

| CAGR | 3.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Herma, Altech Co.,Ltd., Albagnac, E-Packaging Srl, Label-Aire, Etipack, Labelpack, MULTIVAC, Arca Labeling Marking, Packleader |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |