What is Aerospace Metal Forgings - Global Market?

Aerospace metal forgings refer to the process of shaping metals into desired forms for use in the aerospace industry. This market is a crucial segment of the aerospace supply chain, providing essential components for aircraft and spacecraft. Forging involves heating metals to high temperatures and then using compressive forces to shape them into parts like engine components, landing gear, and structural elements. The global market for aerospace metal forgings is driven by the increasing demand for new aircraft, advancements in forging technology, and the need for lightweight yet strong materials. These forgings are vital for ensuring the safety, reliability, and performance of aerospace vehicles. The market is characterized by a diverse range of materials, including steel, titanium, and aluminum, each offering unique properties that cater to specific aerospace applications. As the aerospace industry continues to grow, the demand for high-quality forged components is expected to rise, making this market an integral part of the global aerospace sector.

Steel, Titanium Alloy, Aluminum, Others in the Aerospace Metal Forgings - Global Market:

In the aerospace metal forgings market, various materials are used, each offering distinct advantages. Steel is one of the most commonly used materials due to its strength, durability, and cost-effectiveness. It is often used in components that require high strength and resistance to wear and tear, such as landing gear and engine parts. Steel forgings are known for their ability to withstand extreme conditions, making them ideal for critical aerospace applications. Titanium alloys are another popular choice in the aerospace industry. They are known for their exceptional strength-to-weight ratio, corrosion resistance, and ability to withstand high temperatures. These properties make titanium alloys suitable for use in aircraft engines, airframes, and other components where weight reduction is crucial. The use of titanium in aerospace forgings helps improve fuel efficiency and overall performance of aircraft. Aluminum is also widely used in aerospace forgings due to its lightweight nature and good corrosion resistance. It is often used in structural components, such as fuselage panels and wing structures, where weight savings are essential. Aluminum forgings offer a good balance between strength and weight, making them a preferred choice for many aerospace applications. In addition to steel, titanium, and aluminum, other materials like nickel-based superalloys and magnesium are also used in aerospace forgings. Nickel-based superalloys are known for their high-temperature strength and resistance to oxidation, making them suitable for use in turbine blades and other high-temperature applications. Magnesium, on the other hand, is valued for its lightweight properties and is used in applications where weight reduction is a primary concern. The choice of material in aerospace metal forgings depends on various factors, including the specific application, performance requirements, and cost considerations. Each material offers unique benefits that cater to the diverse needs of the aerospace industry. As technology advances and new materials are developed, the range of options for aerospace metal forgings continues to expand, providing manufacturers with more choices to meet the evolving demands of the market.

Commercial, Military in the Aerospace Metal Forgings - Global Market:

Aerospace metal forgings play a vital role in both commercial and military aviation sectors. In the commercial aviation sector, these forgings are used in the production of various aircraft components, contributing to the overall safety, efficiency, and performance of commercial airplanes. For instance, forged components are used in the construction of aircraft engines, landing gear, and structural parts, ensuring that commercial aircraft can withstand the rigors of frequent flights and varying environmental conditions. The use of high-quality forged materials helps in reducing the weight of the aircraft, thereby improving fuel efficiency and reducing operational costs for airlines. In the military aviation sector, aerospace metal forgings are equally important. Military aircraft require components that can endure extreme conditions, including high speeds, rapid maneuvers, and harsh environments. Forged metal parts are used in the construction of fighter jets, transport aircraft, and helicopters, providing the necessary strength and durability to perform under demanding conditions. The use of advanced materials like titanium alloys and nickel-based superalloys in military aerospace forgings ensures that these aircraft can achieve superior performance and reliability. Additionally, the military sector often demands customized solutions to meet specific mission requirements, and metal forgings offer the flexibility to produce tailored components that meet these needs. The global market for aerospace metal forgings is driven by the continuous demand for new and advanced aircraft in both commercial and military sectors. As airlines expand their fleets to accommodate growing passenger numbers and military forces upgrade their aircraft to enhance capabilities, the need for high-quality forged components is expected to increase. Furthermore, advancements in forging technology and material science are enabling the production of more efficient and lightweight components, further fueling the growth of the aerospace metal forgings market. Overall, the use of aerospace metal forgings in commercial and military aviation is essential for ensuring the safety, performance, and efficiency of aircraft, making it a critical component of the global aerospace industry.

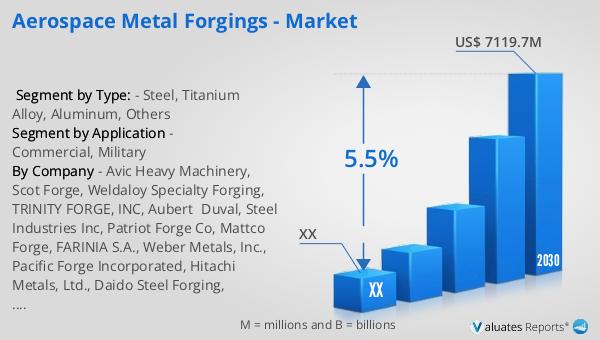

Aerospace Metal Forgings - Global Market Outlook:

The global aerospace metal forgings market was valued at approximately $4,920 million in 2023. It is projected to grow to a revised size of around $7,119.7 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.5% over the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for aerospace metal forgings driven by the expansion of the aerospace industry and the need for advanced materials and components. The North American market, a significant contributor to the global aerospace metal forgings industry, was valued at $ million in 2023. It is expected to reach $ million by 2030, with a CAGR of % during the forecast period from 2024 through 2030. This growth in the North American market is fueled by the presence of major aerospace manufacturers and the continuous demand for new aircraft and components. The market outlook highlights the importance of aerospace metal forgings in meeting the evolving needs of the aerospace industry, ensuring the production of high-quality, reliable, and efficient components for both commercial and military applications. As the market continues to grow, manufacturers are focusing on innovation and technological advancements to enhance the performance and capabilities of aerospace metal forgings, contributing to the overall development of the aerospace sector.

| Report Metric | Details |

| Report Name | Aerospace Metal Forgings - Market |

| Forecasted market size in 2030 | US$ 7119.7 million |

| CAGR | 5.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Avic Heavy Machinery, Scot Forge, Weldaloy Specialty Forging, TRINITY FORGE, INC, Aubert&Duval, Steel Industries Inc, Patriot Forge Co, Mattco Forge, FARINIA S.A., Weber Metals, Inc., Pacific Forge Incorporated, Hitachi Metals, Ltd., Daido Steel Forging, W.H.Tildesley Ltd, RFQ LINE, Inc., Bunty LLC, Arconic, Allegheny Technologies, OTTO FUCHS Kommanditgesellschaft, Steel and Industrial Forgings Ltd, Victoria Drop Forgings |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |