What is Stainless Steel Welding Wire - Global Market?

Stainless steel welding wire is a crucial component in various industries due to its durability, corrosion resistance, and strength. It is primarily used to join stainless steel materials, ensuring a strong and reliable bond. The global market for stainless steel welding wire is expansive, driven by the increasing demand in sectors such as construction, automotive, and manufacturing. As industries continue to grow and evolve, the need for high-quality welding materials like stainless steel welding wire becomes more pronounced. This market is characterized by a diverse range of products, catering to different welding needs and applications. Manufacturers are continually innovating to improve the quality and performance of these wires, making them more efficient and user-friendly. The market is also influenced by technological advancements and the development of new welding techniques, which require specialized wires. Overall, the stainless steel welding wire market is poised for growth, supported by the rising industrialization and infrastructural developments worldwide.

Stainless Steel Flux Cored Welding Wire, Stainless Steel Solid Cored Welding Wire in the Stainless Steel Welding Wire - Global Market:

Stainless steel flux cored welding wire and stainless steel solid cored welding wire are two significant types of welding wires used in the global market. Flux cored welding wire is designed with a flux coating that helps in shielding the weld from atmospheric contamination, making it ideal for outdoor applications or in environments where shielding gas is not feasible. This type of wire is known for its versatility and ease of use, especially in situations where high deposition rates are required. It is commonly used in heavy-duty applications such as shipbuilding, construction, and heavy machinery manufacturing. On the other hand, stainless steel solid cored welding wire is a more traditional type of welding wire, known for its precision and clean welds. It requires an external shielding gas to protect the weld pool from contamination, making it suitable for indoor applications or controlled environments. This type of wire is often used in industries where the appearance and integrity of the weld are critical, such as in the automotive and aerospace sectors. Both types of wires have their unique advantages and are chosen based on the specific requirements of the welding task at hand. The global market for these welding wires is driven by the increasing demand for high-quality welding solutions in various industries. As technology advances, manufacturers are developing new formulations and coatings to enhance the performance and efficiency of these wires. This includes improving their corrosion resistance, strength, and ease of use. The market is also influenced by the growing trend towards automation in welding processes, which requires specialized wires that can withstand the demands of automated systems. Overall, the stainless steel welding wire market is dynamic and continually evolving, with manufacturers striving to meet the changing needs of their customers.

Machinery, Ship Building, Medical, Chemical Industry, Others in the Stainless Steel Welding Wire - Global Market:

Stainless steel welding wire is extensively used across various industries due to its superior properties and versatility. In the machinery industry, it is used to fabricate and repair equipment, ensuring durability and longevity. The strength and corrosion resistance of stainless steel make it an ideal choice for machinery that operates in harsh environments or under heavy loads. In the shipbuilding industry, stainless steel welding wire is crucial for constructing and repairing ships and offshore structures. Its resistance to saltwater corrosion and ability to withstand extreme conditions make it indispensable in this sector. The medical industry also relies on stainless steel welding wire for manufacturing medical devices and equipment. Its biocompatibility and resistance to sterilization processes ensure that medical tools remain safe and effective. In the chemical industry, stainless steel welding wire is used to construct and maintain equipment that handles corrosive substances. Its ability to resist chemical reactions and maintain structural integrity is vital for ensuring safety and efficiency. Other industries, such as food processing and energy, also benefit from the use of stainless steel welding wire due to its hygienic properties and ability to withstand high temperatures. Overall, the versatility and reliability of stainless steel welding wire make it a preferred choice across various sectors, driving its demand in the global market.

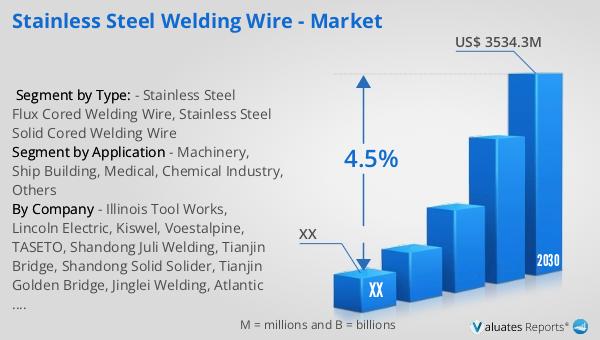

Stainless Steel Welding Wire - Global Market Outlook:

The global market for stainless steel welding wire was valued at approximately $2,591 million in 2023. It is projected to grow to a revised size of $3,534.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.5% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for stainless steel welding wire across various industries, driven by the need for durable and reliable welding solutions. The North American market, in particular, is expected to see significant growth, although specific figures for this region were not provided. The anticipated growth in the global market is supported by the rising industrialization and infrastructural developments worldwide, which require high-quality welding materials. As industries continue to expand and evolve, the demand for stainless steel welding wire is expected to increase, further driving market growth. The market outlook suggests a positive trajectory for the stainless steel welding wire industry, with manufacturers focusing on innovation and quality to meet the changing needs of their customers.

| Report Metric | Details |

| Report Name | Stainless Steel Welding Wire - Market |

| Forecasted market size in 2030 | US$ 3534.3 million |

| CAGR | 4.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Illinois Tool Works, Lincoln Electric, Kiswel, Voestalpine, TASETO, Shandong Juli Welding, Tianjin Bridge, Shandong Solid Solider, Tianjin Golden Bridge, Jinglei Welding, Atlantic China Welding Consumables, Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |