What is PC Light Diffusion Plate - Global Market?

PC Light Diffusion Plates are specialized components used in various lighting applications to evenly distribute light and reduce glare. These plates are made from polycarbonate (PC), a durable and versatile plastic known for its excellent light transmission and impact resistance. The global market for PC Light Diffusion Plates is driven by the increasing demand for energy-efficient lighting solutions and the growing adoption of LED technology. These plates are essential in enhancing the performance and aesthetic appeal of lighting fixtures by ensuring uniform light distribution. They are widely used in residential, commercial, and industrial settings, where consistent and high-quality lighting is crucial. The market is characterized by continuous innovation, with manufacturers focusing on developing plates with improved light diffusion properties and enhanced durability. As the demand for sustainable and efficient lighting solutions continues to rise, the PC Light Diffusion Plate market is expected to experience steady growth, driven by advancements in material science and manufacturing technologies. The versatility and effectiveness of these plates make them a vital component in modern lighting systems, contributing to energy savings and improved visual comfort.

0.5mm, 0.7mm, 1.0mm, 1.5mm, Others in the PC Light Diffusion Plate - Global Market:

In the global market for PC Light Diffusion Plates, thickness variations such as 0.5mm, 0.7mm, 1.0mm, and 1.5mm play a significant role in catering to diverse application needs. Each thickness offers unique properties that make them suitable for specific uses. The 0.5mm plates are typically used in applications where minimal weight and high flexibility are required. These ultra-thin plates are ideal for compact lighting fixtures and devices where space is a constraint. Despite their thinness, they provide excellent light diffusion, making them a popular choice for portable lighting solutions and small-scale electronic displays. On the other hand, the 0.7mm plates offer a balance between flexibility and durability. They are commonly used in medium-sized lighting fixtures and displays, providing a good compromise between weight and strength. These plates are often employed in commercial lighting applications where moderate durability and efficient light diffusion are necessary. The 1.0mm plates are among the most versatile, offering a robust solution for a wide range of applications. They are frequently used in both residential and commercial settings, providing excellent light diffusion and impact resistance. These plates are ideal for larger lighting fixtures and displays, where durability and performance are critical. The 1.5mm plates are the thickest among the standard options, offering maximum durability and impact resistance. They are used in heavy-duty applications where the lighting fixtures are exposed to harsh environments or require additional protection. These plates are commonly found in industrial settings, outdoor lighting solutions, and large-scale displays. Beyond these standard thicknesses, the market also offers customized options to meet specific requirements. Manufacturers are increasingly focusing on developing plates with unique properties, such as enhanced UV resistance, improved thermal stability, and specialized surface textures to cater to niche markets. The availability of various thickness options allows designers and engineers to select the most appropriate solution for their specific needs, ensuring optimal performance and longevity of the lighting systems. As the demand for customized and high-performance lighting solutions grows, the market for PC Light Diffusion Plates is expected to expand, driven by innovations in material science and manufacturing processes. The ability to tailor the properties of these plates to specific applications makes them an indispensable component in modern lighting design, contributing to energy efficiency, visual comfort, and aesthetic appeal.

LED Lighting, LCD, Others in the PC Light Diffusion Plate - Global Market:

PC Light Diffusion Plates are extensively used in various applications, including LED lighting, LCD displays, and other areas where uniform light distribution is essential. In LED lighting, these plates play a crucial role in enhancing the performance and efficiency of the fixtures. They help in evenly distributing the light emitted by the LEDs, reducing glare and hotspots, and improving the overall visual comfort. This is particularly important in environments where high-quality lighting is required, such as offices, retail spaces, and residential areas. The use of PC Light Diffusion Plates in LED lighting also contributes to energy savings by maximizing the light output and minimizing wastage. In LCD displays, these plates are used to ensure uniform backlighting, which is critical for achieving high-quality image reproduction. They help in distributing the light evenly across the display, enhancing the brightness and contrast of the images. This is particularly important in applications such as televisions, computer monitors, and mobile devices, where image quality is a key consideration. The use of PC Light Diffusion Plates in LCD displays also contributes to the overall durability and longevity of the devices, as they provide protection against impact and environmental factors. Beyond LED lighting and LCD displays, PC Light Diffusion Plates are also used in a variety of other applications, including signage, automotive lighting, and architectural lighting. In signage, these plates help in achieving uniform illumination, enhancing the visibility and attractiveness of the signs. In automotive lighting, they contribute to the performance and safety of the lighting systems by ensuring consistent light distribution. In architectural lighting, these plates are used to create visually appealing and energy-efficient lighting solutions, enhancing the aesthetic appeal of the spaces. The versatility and effectiveness of PC Light Diffusion Plates make them a valuable component in a wide range of applications, contributing to improved performance, energy efficiency, and visual comfort. As the demand for high-quality and sustainable lighting solutions continues to grow, the use of PC Light Diffusion Plates is expected to increase, driven by advancements in material science and manufacturing technologies. The ability to customize these plates to meet specific application needs further enhances their appeal, making them an indispensable component in modern lighting design.

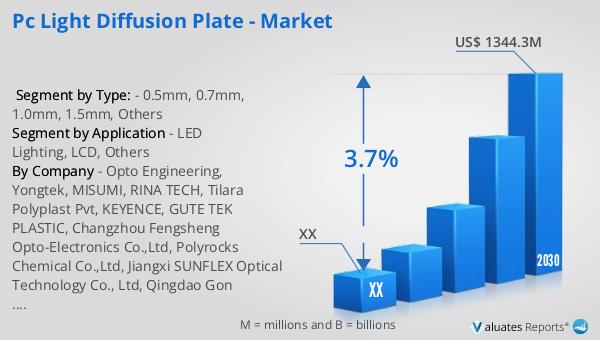

PC Light Diffusion Plate - Global Market Outlook:

The global market for PC Light Diffusion Plates was valued at approximately $1,039 million in 2023. It is projected to grow to a revised size of about $1,344.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.7% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for efficient and high-quality lighting solutions across various sectors. The North American market, in particular, is expected to see significant growth, although specific figures for this region were not provided. The anticipated expansion in the market size underscores the growing importance of PC Light Diffusion Plates in modern lighting applications. These plates are becoming increasingly vital due to their ability to enhance light distribution and improve energy efficiency. As industries continue to prioritize sustainable and efficient lighting solutions, the demand for PC Light Diffusion Plates is likely to rise, contributing to the overall growth of the market. The projected growth also highlights the ongoing advancements in material science and manufacturing technologies, which are enabling the development of more effective and durable light diffusion plates. As a result, the market is poised for steady expansion, driven by the need for innovative and high-performance lighting solutions.

| Report Metric | Details |

| Report Name | PC Light Diffusion Plate - Market |

| Forecasted market size in 2030 | US$ 1344.3 million |

| CAGR | 3.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Opto Engineering, Yongtek, MISUMI, RINA TECH, Tilara Polyplast Pvt, KEYENCE, GUTE TEK PLASTIC, Changzhou Fengsheng Opto-Electronics Co.,Ltd, Polyrocks Chemical Co.,Ltd, Jiangxi SUNFLEX Optical Technology Co., Ltd, Qingdao Gon Technology Co.,Ltd, Changzhou Fusion New Material Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |