What is Lithium Battery Mid-end Equipment - Global Market?

Lithium Battery Mid-end Equipment refers to the machinery and tools used in the intermediate stages of lithium battery production. This equipment plays a crucial role in ensuring the efficiency, quality, and performance of lithium batteries, which are essential for powering a wide range of devices from smartphones to electric vehicles. The global market for this equipment is expanding rapidly due to the increasing demand for lithium batteries driven by the rise in electric vehicle adoption and renewable energy storage solutions. Mid-end equipment includes machines for winding, laminating, drying, and filling, among others, each contributing to different stages of battery assembly. These machines are designed to handle the delicate and precise processes required to produce high-quality batteries that meet industry standards. As the demand for lithium batteries continues to grow, so does the need for advanced mid-end equipment that can enhance production capabilities and improve battery performance. This market is characterized by technological advancements and innovations aimed at increasing production efficiency and reducing costs, making it a dynamic and competitive sector within the broader battery manufacturing industry.

Winding Machine, Laminating Machine, Drying Machine, Filling Machine, Others in the Lithium Battery Mid-end Equipment - Global Market:

The Winding Machine is a critical component in the lithium battery mid-end equipment market. It is responsible for winding the electrode materials into a specific shape, which is essential for the battery's structure and performance. This machine ensures that the electrodes are wound tightly and uniformly, which is crucial for maintaining the battery's capacity and longevity. The precision of the winding process directly affects the battery's efficiency and safety, making it a vital piece of equipment in the production line. Laminating Machines, on the other hand, are used to layer the electrodes with separators, which prevent short circuits and enhance the battery's stability. This process requires high precision to ensure that the layers are evenly distributed and securely bonded, which is essential for the battery's overall performance. Drying Machines play a significant role in removing moisture from the electrodes and separators, which is crucial for preventing chemical reactions that could compromise the battery's integrity. These machines use advanced drying techniques to ensure that the materials are thoroughly dried without causing any damage. Filling Machines are used to inject the electrolyte into the battery cells, a process that requires extreme precision to ensure that the right amount of electrolyte is used. This step is critical for the battery's performance and safety, as too much or too little electrolyte can lead to malfunctions or reduced efficiency. Other equipment in the mid-end market includes machines for cutting, stacking, and assembling the battery components, each playing a vital role in ensuring the quality and performance of the final product. These machines are designed to work seamlessly together, creating a streamlined production process that maximizes efficiency and minimizes waste. As the demand for lithium batteries continues to rise, manufacturers are investing in advanced mid-end equipment to enhance their production capabilities and meet the growing needs of the market.

Square Battery, Cylindrical Battery, Soft Pack Battery in the Lithium Battery Mid-end Equipment - Global Market:

Lithium Battery Mid-end Equipment is used in the production of various types of batteries, including square, cylindrical, and soft pack batteries. Each type of battery has its unique characteristics and applications, which influence the choice of equipment used in their production. Square batteries, also known as prismatic batteries, are commonly used in electric vehicles and energy storage systems due to their high energy density and compact design. The production of square batteries requires precise equipment to ensure that the electrodes are cut and stacked accurately, which is essential for maximizing the battery's capacity and performance. Cylindrical batteries, on the other hand, are widely used in consumer electronics and power tools due to their durability and ease of manufacturing. The winding process is particularly important for cylindrical batteries, as it determines the battery's internal structure and affects its overall performance. Soft pack batteries, also known as pouch batteries, are favored for their lightweight and flexible design, making them ideal for portable devices and wearable technology. The production of soft pack batteries requires specialized equipment to handle the delicate materials and ensure that the battery is sealed properly to prevent leaks and enhance safety. Each type of battery requires a specific set of mid-end equipment to ensure that the production process is efficient and the final product meets the required standards. As the demand for different types of lithium batteries continues to grow, manufacturers are investing in advanced mid-end equipment to enhance their production capabilities and meet the diverse needs of the market.

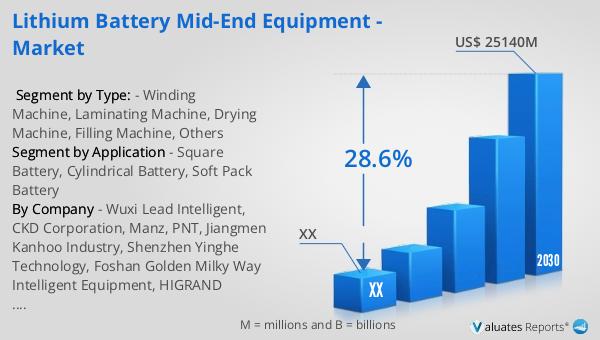

Lithium Battery Mid-end Equipment - Global Market Outlook:

In 2023, the global market for Lithium Battery Mid-end Equipment was valued at approximately US$ 4,392 million. It is projected to grow significantly, reaching an estimated size of US$ 25,140 million by 2030, with a compound annual growth rate (CAGR) of 28.6% during the forecast period from 2024 to 2030. This growth is largely driven by the increasing demand for lithium-ion batteries, particularly in China, where government policies are heavily focused on promoting new energy vehicles and battery production. In 2022, China's new energy vehicle sales reached 6.8 million units, accounting for 63.6% of the global market share. In contrast, Europe had a penetration rate of 19%, while North America lagged behind with only 6%. According to the Ministry of Industry and Information Technology, China's lithium-ion battery production reached 750 GWh in 2022, marking a year-on-year increase of over 130%. This rapid growth in production capacity is a testament to the country's commitment to becoming a global leader in the lithium battery industry. As the market continues to expand, manufacturers are focusing on developing advanced mid-end equipment to enhance production efficiency and meet the growing demand for high-quality lithium batteries.

| Report Metric | Details |

| Report Name | Lithium Battery Mid-end Equipment - Market |

| Forecasted market size in 2030 | US$ 25140 million |

| CAGR | 28.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Wuxi Lead Intelligent, CKD Corporation, Manz, PNT, Jiangmen Kanhoo Industry, Shenzhen Yinghe Technology, Foshan Golden Milky Way Intelligent Equipment, HIGRAND Technology, Chengjie Intelligent Equipment, Shenzhen Colibri, Kaido Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |