What is Carbon Fiber CNG Storage Tank - Global Market?

Carbon fiber CNG storage tanks are a crucial component in the global market for compressed natural gas (CNG) storage solutions. These tanks are designed to store CNG, which is a cleaner alternative to traditional fossil fuels, in a safe and efficient manner. Carbon fiber is used in the construction of these tanks due to its high strength-to-weight ratio, which allows for lighter and more durable storage solutions compared to traditional steel tanks. This lightweight nature not only improves fuel efficiency in vehicles but also enhances the overall performance of the storage system. The global market for carbon fiber CNG storage tanks is driven by the increasing demand for environmentally friendly fuel alternatives and the growing adoption of CNG vehicles. As more countries implement stringent emission regulations, the need for efficient and reliable CNG storage solutions is expected to rise, further propelling the market growth. The market is characterized by technological advancements aimed at improving the safety, efficiency, and cost-effectiveness of these storage tanks, making them a viable option for both automotive and industrial applications.

Type III, Type IV, Others in the Carbon Fiber CNG Storage Tank - Global Market:

In the realm of carbon fiber CNG storage tanks, there are primarily three types: Type III, Type IV, and others, each with distinct characteristics and applications. Type III tanks are composed of a metal liner, typically aluminum, wrapped with a carbon fiber composite. This combination provides a balance between weight and strength, making them suitable for various applications, including automotive and industrial uses. The metal liner offers excellent gas impermeability, while the carbon fiber wrapping ensures structural integrity and durability. Type III tanks are often favored for their cost-effectiveness and reliability, especially in applications where weight is a critical factor. On the other hand, Type IV tanks are entirely made of composite materials, with a plastic liner wrapped in carbon fiber. This design results in even lighter tanks compared to Type III, offering superior weight savings and corrosion resistance. Type IV tanks are particularly popular in the automotive industry, where reducing vehicle weight is crucial for enhancing fuel efficiency and performance. The absence of metal components in Type IV tanks also eliminates the risk of corrosion, making them ideal for long-term use in harsh environments. Additionally, the flexibility in design and manufacturing processes allows for customized solutions tailored to specific application requirements. Beyond Type III and Type IV, there are other variations of carbon fiber CNG storage tanks that cater to niche markets and specialized applications. These may include hybrid designs that combine features of both Type III and Type IV tanks or entirely new configurations developed through ongoing research and innovation. The choice between these types depends on factors such as cost, weight, durability, and specific application needs. As the demand for CNG storage solutions continues to grow, manufacturers are investing in research and development to enhance the performance and cost-effectiveness of these tanks. This includes exploring new materials, manufacturing techniques, and design innovations to meet the evolving needs of the market. The global market for carbon fiber CNG storage tanks is poised for significant growth, driven by the increasing adoption of CNG as a cleaner and more sustainable fuel alternative. As industries and consumers alike seek to reduce their carbon footprint, the demand for efficient and reliable CNG storage solutions is expected to rise, further fueling the development and adoption of advanced carbon fiber CNG storage tanks.

Passenger Car, Commercial Vehicle in the Carbon Fiber CNG Storage Tank - Global Market:

Carbon fiber CNG storage tanks play a pivotal role in the automotive industry, particularly in passenger cars and commercial vehicles. In passenger cars, these tanks are increasingly being adopted due to their lightweight nature, which contributes to improved fuel efficiency and reduced emissions. As consumers become more environmentally conscious, the demand for vehicles powered by cleaner fuels like CNG is on the rise. Carbon fiber CNG storage tanks offer a viable solution by providing a safe and efficient means of storing CNG, enabling automakers to design vehicles that meet stringent emission standards without compromising on performance. The lightweight nature of carbon fiber tanks also allows for greater design flexibility, enabling manufacturers to optimize vehicle space and enhance overall driving experience. In commercial vehicles, the use of carbon fiber CNG storage tanks is driven by the need for cost-effective and sustainable fuel solutions. Commercial fleets, such as buses and trucks, are significant contributors to greenhouse gas emissions, and the transition to CNG-powered vehicles is seen as a viable strategy to mitigate environmental impact. Carbon fiber CNG storage tanks offer the durability and reliability required for commercial applications, ensuring safe and efficient fuel storage even under demanding conditions. The reduced weight of these tanks translates to increased payload capacity and improved fuel economy, making them an attractive option for fleet operators looking to reduce operational costs and enhance sustainability. Furthermore, the adoption of carbon fiber CNG storage tanks in commercial vehicles is supported by government incentives and regulations aimed at promoting cleaner transportation solutions. As more countries implement policies to curb emissions and promote the use of alternative fuels, the demand for carbon fiber CNG storage tanks in the commercial vehicle sector is expected to grow. This trend is further bolstered by advancements in tank design and manufacturing processes, which continue to improve the performance and cost-effectiveness of these storage solutions. Overall, the use of carbon fiber CNG storage tanks in passenger cars and commercial vehicles represents a significant step towards achieving a more sustainable and environmentally friendly transportation sector.

Carbon Fiber CNG Storage Tank - Global Market Outlook:

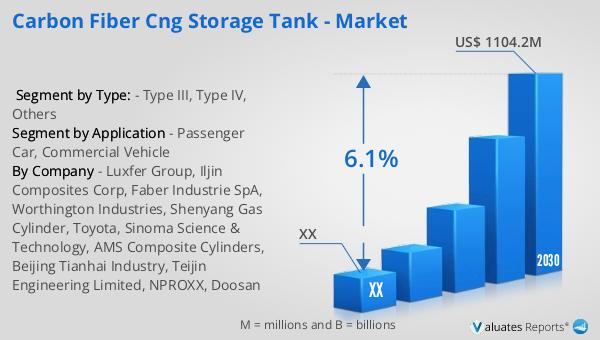

The global market for carbon fiber CNG storage tanks was valued at approximately $724 million in 2023, with projections indicating a growth to around $1,104.2 million by 2030. This represents a compound annual growth rate (CAGR) of 6.1% during the forecast period from 2024 to 2030. The North American segment of this market was also valued at a significant amount in 2023, with expectations of continued growth through 2030. The increasing adoption of CNG as a cleaner fuel alternative, coupled with advancements in carbon fiber technology, is driving this market expansion. The lightweight and durable nature of carbon fiber CNG storage tanks makes them an attractive option for various applications, including automotive and industrial sectors. As more countries implement stringent emission regulations and promote the use of alternative fuels, the demand for efficient and reliable CNG storage solutions is expected to rise. This growth is further supported by ongoing research and development efforts aimed at enhancing the performance and cost-effectiveness of carbon fiber CNG storage tanks. As a result, the global market for these storage solutions is poised for significant growth in the coming years, driven by the increasing need for sustainable and environmentally friendly fuel alternatives.

| Report Metric | Details |

| Report Name | Carbon Fiber CNG Storage Tank - Market |

| Forecasted market size in 2030 | US$ 1104.2 million |

| CAGR | 6.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Luxfer Group, Iljin Composites Corp, Faber Industrie SpA, Worthington Industries, Shenyang Gas Cylinder, Toyota, Sinoma Science & Technology, AMS Composite Cylinders, Beijing Tianhai Industry, Teijin Engineering Limited, NPROXX, Doosan |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |