What is Carbon Black Masterbatch - Global Market?

Carbon Black Masterbatch is a concentrated mixture of carbon black pigment and a carrier resin, which is used to impart color and enhance the properties of plastic products. This masterbatch is widely used in the plastics industry due to its ability to provide a deep black color, UV protection, and improved conductivity. The global market for Carbon Black Masterbatch is driven by its extensive application across various industries, including automotive, packaging, construction, and electronics. The demand for high-performance plastics with enhanced durability and aesthetic appeal is a significant factor contributing to the growth of this market. Additionally, the increasing focus on sustainable and eco-friendly materials has led to innovations in the formulation of carbon black masterbatches, further boosting their adoption. The market is characterized by a diverse range of products tailored to meet specific industry requirements, with manufacturers continuously investing in research and development to enhance product performance and expand their application scope. As industries continue to evolve and demand more sophisticated materials, the Carbon Black Masterbatch market is poised for steady growth, driven by technological advancements and the rising need for high-quality plastic solutions.

PE Carbon Black Masterbatch, PP Carbon Black Masterbatch, PS Carbon Black Masterbatch, Others in the Carbon Black Masterbatch - Global Market:

PE Carbon Black Masterbatch, PP Carbon Black Masterbatch, PS Carbon Black Masterbatch, and other variants play a crucial role in the global Carbon Black Masterbatch market, each serving distinct applications and industries. PE (Polyethylene) Carbon Black Masterbatch is predominantly used in packaging, agricultural films, and household products due to its excellent processability and compatibility with polyethylene resins. It provides UV resistance and enhances the mechanical properties of the end products, making them more durable and long-lasting. PP (Polypropylene) Carbon Black Masterbatch is favored in automotive components, textiles, and consumer goods, offering high thermal stability and resistance to chemicals. Its ability to improve the aesthetic appeal and performance of polypropylene products makes it a preferred choice in various applications. PS (Polystyrene) Carbon Black Masterbatch is utilized in the production of electronic housings, toys, and packaging materials, where it imparts a glossy finish and enhances the impact strength of polystyrene products. Other types of Carbon Black Masterbatch cater to niche applications, such as conductive masterbatches used in electronics and antistatic packaging. These specialized masterbatches are formulated to meet specific industry standards and requirements, ensuring optimal performance and functionality. The global market for Carbon Black Masterbatch is characterized by a diverse range of products, each designed to address the unique needs of different industries. Manufacturers are continually innovating to develop new formulations that offer enhanced properties, such as improved UV resistance, conductivity, and color consistency. This focus on innovation and customization is driving the growth of the Carbon Black Masterbatch market, as industries seek advanced materials that can meet their evolving demands. The market is also witnessing a shift towards sustainable and eco-friendly solutions, with manufacturers exploring bio-based and recycled materials to reduce the environmental impact of their products. As a result, the Carbon Black Masterbatch market is poised for steady growth, driven by technological advancements and the increasing demand for high-performance plastic solutions across various industries.

Injection/ Blow Moulding, Pipe Extrusion, Wire & Cable, Film Extrusion, Others in the Carbon Black Masterbatch - Global Market:

Carbon Black Masterbatch is extensively used in various applications, including Injection/Blow Moulding, Pipe Extrusion, Wire & Cable, Film Extrusion, and others, due to its ability to enhance the properties of plastic products. In Injection/Blow Moulding, Carbon Black Masterbatch is used to produce a wide range of products, from automotive components to household items, by providing a deep black color and improving the mechanical properties of the molded parts. It enhances the UV resistance and durability of the products, making them suitable for outdoor applications. In Pipe Extrusion, Carbon Black Masterbatch is used to manufacture pipes with enhanced UV stability and resistance to environmental stress cracking. This ensures the longevity and reliability of the pipes, especially in outdoor and harsh environments. In the Wire & Cable industry, Carbon Black Masterbatch is used to provide electrical conductivity and UV protection to the insulation and jacketing materials, ensuring the safety and performance of the cables. Film Extrusion is another significant application area, where Carbon Black Masterbatch is used to produce agricultural films, packaging films, and geomembranes with improved UV resistance and mechanical strength. These films are widely used in agriculture, construction, and packaging industries, where durability and performance are critical. Other applications of Carbon Black Masterbatch include the production of automotive parts, electronic housings, and consumer goods, where it enhances the aesthetic appeal and functional properties of the products. The versatility and performance benefits of Carbon Black Masterbatch make it an essential component in the plastics industry, driving its demand across various applications and industries.

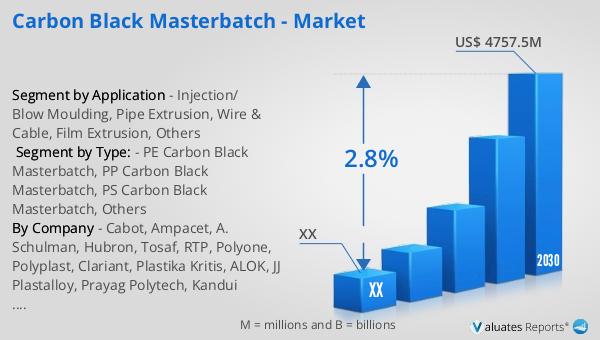

Carbon Black Masterbatch - Global Market Outlook:

The global market for Carbon Black Masterbatch was valued at approximately $3,932 million in 2023, and it is projected to grow to a revised size of around $4,757.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.8% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-performance plastics across various industries, including automotive, packaging, construction, and electronics. The North American market for Carbon Black Masterbatch, although not specified in exact figures, is expected to follow a similar growth trajectory, driven by technological advancements and the rising need for durable and aesthetically appealing plastic products. The market's expansion is supported by the continuous innovation and development of new formulations that offer enhanced properties, such as improved UV resistance, conductivity, and color consistency. As industries continue to evolve and demand more sophisticated materials, the Carbon Black Masterbatch market is poised for steady growth, driven by technological advancements and the rising need for high-quality plastic solutions. The focus on sustainability and eco-friendly materials is also contributing to the market's growth, as manufacturers explore bio-based and recycled materials to reduce the environmental impact of their products.

| Report Metric | Details |

| Report Name | Carbon Black Masterbatch - Market |

| Forecasted market size in 2030 | US$ 4757.5 million |

| CAGR | 2.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Cabot, Ampacet, A. Schulman, Hubron, Tosaf, RTP, Polyone, Polyplast, Clariant, Plastika Kritis, ALOK, JJ Plastalloy, Prayag Polytech, Kandui Industries, Malson Polymer, NGAI XingHang, Heima, Jolink, Shencai, Wdlongda, E-luck, Malion, Bolong, Yiyuan |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |