What is Rubber Carbon Black - Global Market?

Rubber carbon black is a crucial component in the global market, primarily used as a reinforcing agent in rubber products. It is a fine black powder produced by the incomplete combustion of heavy petroleum products. This material is essential in enhancing the strength, durability, and overall performance of rubber, making it indispensable in various industries. The global market for rubber carbon black is driven by its extensive application in the automotive sector, particularly in tire manufacturing. As the demand for vehicles continues to rise, so does the need for high-quality tires, which in turn fuels the demand for rubber carbon black. Additionally, this material is used in other rubber products such as hoses, belts, and gaskets, further broadening its market scope. The versatility and effectiveness of rubber carbon black make it a vital component in the production of durable and high-performance rubber goods, ensuring its continued relevance in the global market.

Thermal Black in the Rubber Carbon Black - Global Market:

Thermal black is a specific type of carbon black used in the rubber carbon black global market, known for its unique properties and applications. Unlike other types of carbon black, thermal black is produced through a thermal decomposition process, which involves heating hydrocarbons in a controlled environment without the presence of oxygen. This process results in a carbon black with larger particle sizes and lower structure, making it distinct from other carbon blacks like furnace black. The larger particle size of thermal black contributes to its lower surface area, which in turn affects its reinforcing properties. While it may not provide the same level of reinforcement as other carbon blacks, thermal black offers other advantages that make it valuable in specific applications. One of the primary uses of thermal black is in the production of rubber products that require a softer texture and greater flexibility. Its lower reinforcing properties make it ideal for applications where high elasticity and resilience are desired, such as in certain types of rubber seals and gaskets. Additionally, thermal black is used in the production of rubber compounds that require a smooth surface finish, as its larger particle size helps achieve this effect. In the tire industry, thermal black is often used in the inner liners of tires, where its properties help maintain air retention and improve the overall performance of the tire. The use of thermal black in this application is crucial, as it contributes to the tire's ability to maintain proper inflation, which is essential for safety and fuel efficiency. Beyond the tire industry, thermal black finds applications in other rubber products such as hoses, belts, and vibration dampening components. Its unique properties make it suitable for products that require a balance between flexibility and durability. Furthermore, thermal black is used in non-rubber applications, including coatings, plastics, and inks, where its larger particle size and lower structure can be advantageous. In coatings, for example, thermal black can provide a smooth finish and enhance the visual appeal of the final product. In plastics, it can improve the material's UV resistance and overall stability. The versatility of thermal black makes it a valuable component in various industries, contributing to its demand in the global market. As industries continue to seek materials that offer specific performance characteristics, the role of thermal black in the rubber carbon black market is likely to remain significant. Its ability to provide unique properties that differ from other carbon blacks ensures its continued relevance and application in diverse sectors.

Tire Rubber, Other Rubber Prouducts, Non-Tire Rubber, Others in the Rubber Carbon Black - Global Market:

Rubber carbon black plays a significant role in various applications, particularly in the tire rubber, other rubber products, non-tire rubber, and other sectors. In the tire industry, rubber carbon black is a critical component used to enhance the performance and longevity of tires. It acts as a reinforcing filler, improving the tensile strength, abrasion resistance, and overall durability of the rubber. This is essential for tires, as they need to withstand various road conditions and provide a safe driving experience. The use of rubber carbon black in tire manufacturing also contributes to better fuel efficiency and reduced rolling resistance, making it an indispensable material in the automotive sector. Beyond tires, rubber carbon black is used in a wide range of other rubber products. These include hoses, belts, gaskets, and seals, where its reinforcing properties help improve the mechanical performance and lifespan of the products. In these applications, rubber carbon black enhances the elasticity, resilience, and resistance to wear and tear, ensuring that the products can withstand demanding conditions and maintain their functionality over time. In the non-tire rubber sector, rubber carbon black is used in products such as conveyor belts, footwear, and industrial rubber goods. Its ability to improve the strength and durability of rubber makes it a valuable component in these applications, where the materials are often subjected to heavy use and harsh environments. The use of rubber carbon black in these products helps ensure that they can perform reliably and efficiently, meeting the demands of various industries. Additionally, rubber carbon black finds applications in other sectors, including the production of coatings, plastics, and inks. In these applications, it is used to enhance the color, UV resistance, and overall stability of the materials. The versatility of rubber carbon black makes it a valuable component in a wide range of products, contributing to its demand in the global market. As industries continue to seek materials that offer improved performance and durability, the role of rubber carbon black in various applications is likely to remain significant. Its ability to enhance the properties of rubber and other materials ensures its continued relevance and application in diverse sectors.

Rubber Carbon Black - Global Market Outlook:

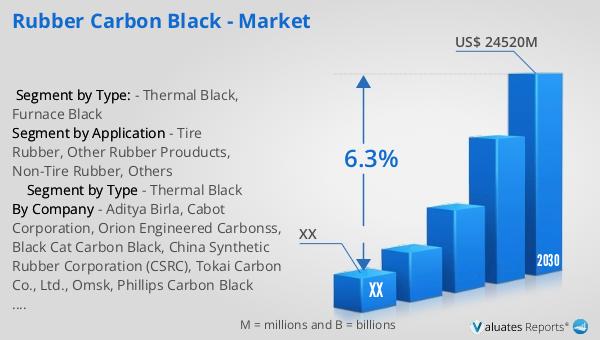

The global market for rubber carbon black was valued at approximately $16,080 million in 2023. This market is projected to grow significantly, reaching an estimated size of $24,520 million by the year 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.3% during the forecast period from 2024 to 2030. The North American market for rubber carbon black also shows promising growth potential. Although specific figures for the North American market in 2023 and 2030 are not provided, it is anticipated to experience a steady increase in demand and market size throughout the forecast period. The growth in the global and North American markets can be attributed to the increasing demand for rubber carbon black in various industries, particularly in the automotive sector. As the demand for high-performance tires and other rubber products continues to rise, the market for rubber carbon black is expected to expand accordingly. The projected growth in the market reflects the ongoing need for materials that enhance the performance and durability of rubber products, ensuring their continued relevance in the global market.

| Report Metric | Details |

| Report Name | Rubber Carbon Black - Market |

| Forecasted market size in 2030 | US$ 24520 million |

| CAGR | 6.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Aditya Birla, Cabot Corporation, Orion Engineered Carbonss, Black Cat Carbon Black, China Synthetic Rubber Corporation (CSRC), Tokai Carbon Co., Ltd., Omsk, Phillips Carbon Black Limited, Sid Richardson, Longxing Chemical, HUADONG RUBBER MATERIAL, BAOHUA, JINNENG, DAGUANGMING GROUP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |