What is Wire Wound Filter Material - Global Market?

Wire wound filter materials are essential components in various filtration systems, designed to remove impurities and contaminants from liquids and gases. These filters are made by tightly winding a yarn or thread around a core, creating a dense and effective filtration medium. The global market for wire wound filter materials is driven by the increasing demand for clean water, stringent environmental regulations, and the need for efficient filtration solutions in various industries. These filters are widely used in water and wastewater treatment, chemical processing, petrochemical industries, and food and beverage production. The market is characterized by a diverse range of materials used for the yarn, including polypropylene, cotton, and other synthetic fibers, each offering unique benefits in terms of filtration efficiency, chemical resistance, and cost-effectiveness. As industries continue to prioritize sustainability and operational efficiency, the demand for advanced filtration solutions like wire wound filters is expected to grow, making this market a critical component of the global filtration industry.

Polypropylene Yarn, Cotton Yarn in the Wire Wound Filter Material - Global Market:

Polypropylene yarn and cotton yarn are two of the most commonly used materials in the production of wire wound filters, each offering distinct advantages and applications. Polypropylene yarn is favored for its excellent chemical resistance, making it ideal for use in environments where the filter may be exposed to harsh chemicals or solvents. This material is also lightweight, durable, and resistant to bacterial growth, which is crucial in maintaining the integrity and longevity of the filter. Polypropylene yarn-based filters are often used in industries such as chemical processing, petrochemical, and water treatment, where the ability to withstand aggressive substances is paramount. On the other hand, cotton yarn is a natural fiber known for its high absorbency and biodegradability. Cotton yarn-based filters are particularly effective in applications where the removal of fine particles is necessary, such as in the food and beverage industry. The natural fibers provide a dense filtration medium that can capture small contaminants, ensuring the purity and quality of the final product. Additionally, cotton yarn is a more environmentally friendly option, appealing to industries that prioritize sustainability and eco-friendly practices. The choice between polypropylene and cotton yarn in wire wound filters ultimately depends on the specific requirements of the application, including the type of contaminants to be removed, the operating environment, and the desired balance between cost and performance. As the global market for wire wound filter materials continues to expand, manufacturers are investing in research and development to enhance the properties of these yarns, aiming to improve filtration efficiency, durability, and environmental impact. This ongoing innovation is expected to drive further growth in the market, as industries seek more effective and sustainable filtration solutions to meet their evolving needs.

Water and Wastewater Treatment, Chemical and Petrochemical, Food and Drink in the Wire Wound Filter Material - Global Market:

Wire wound filter materials play a crucial role in various industries, particularly in water and wastewater treatment, chemical and petrochemical processing, and the food and drink sector. In water and wastewater treatment, these filters are essential for removing suspended solids, sediments, and other impurities from water, ensuring it meets safety and quality standards. The ability of wire wound filters to handle high flow rates and their compatibility with different filtration systems make them a preferred choice for municipal and industrial water treatment facilities. In the chemical and petrochemical industries, wire wound filters are used to protect equipment and processes from contamination by filtering out particulates and impurities from raw materials and finished products. The chemical resistance of materials like polypropylene yarn makes these filters suitable for handling aggressive chemicals and solvents, ensuring the smooth operation of production processes. In the food and drink industry, wire wound filters are employed to maintain the purity and quality of products by removing contaminants such as sediments, bacteria, and other impurities. The use of natural fibers like cotton yarn in these filters is particularly beneficial, as it aligns with the industry's focus on sustainability and eco-friendly practices. Overall, the versatility and effectiveness of wire wound filter materials make them indispensable in these sectors, contributing to improved product quality, operational efficiency, and environmental compliance.

Wire Wound Filter Material - Global Market Outlook:

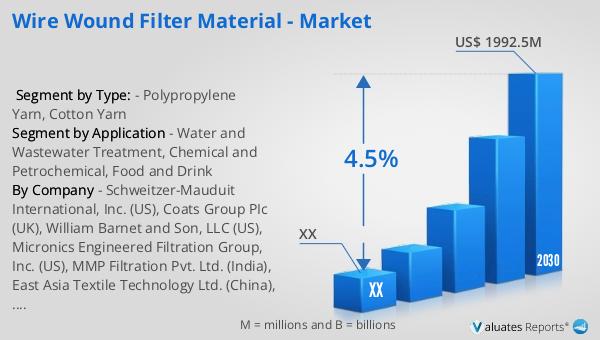

The global market for wire wound filter materials was valued at approximately $1.4 billion in 2023, with projections indicating a growth to around $1.992 billion by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030. The North American segment of this market also shows promising potential, although specific figures for 2023 and 2030 are not provided. The anticipated growth in this region is driven by increasing industrial activities, stringent environmental regulations, and the rising demand for efficient filtration solutions across various sectors. The market's expansion is further supported by technological advancements in filtration materials and processes, which enhance the performance and lifespan of wire wound filters. As industries continue to prioritize sustainability and operational efficiency, the demand for advanced filtration solutions like wire wound filters is expected to grow, making this market a critical component of the global filtration industry. The ongoing innovation and development in this field are likely to open new opportunities for manufacturers and suppliers, as they strive to meet the evolving needs of their customers and maintain a competitive edge in the market.

| Report Metric | Details |

| Report Name | Wire Wound Filter Material - Market |

| Forecasted market size in 2030 | US$ 1992.5 million |

| CAGR | 4.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Schweitzer-Mauduit International, Inc. (US), Coats Group PIc (UK), William Barnet and Son, LLC (US), Micronics Engineered Filtration Group, Inc. (US), MMP Filtration Pvt. Ltd. (India), East Asia Textile Technology Ltd. (China), STRADOM S.A (Poland), United Filters International (US) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |