What is UV Curable Oligomer - Global Market?

UV curable oligomers are specialized compounds used in the formulation of coatings, inks, and adhesives that cure or harden upon exposure to ultraviolet (UV) light. These oligomers are a key component in UV-curable systems, which are valued for their rapid curing times, low energy consumption, and reduced environmental impact compared to traditional curing methods. The global market for UV curable oligomers is driven by the increasing demand for eco-friendly and efficient curing technologies across various industries, including automotive, electronics, and packaging. These oligomers offer excellent performance characteristics such as high gloss, chemical resistance, and durability, making them suitable for a wide range of applications. The market is characterized by continuous innovation and development of new oligomer chemistries to meet the evolving needs of end-users. As industries strive for more sustainable and efficient production processes, the adoption of UV curable oligomers is expected to grow, supported by advancements in UV curing technology and the increasing availability of raw materials. The global market for UV curable oligomers is poised for significant growth, driven by technological advancements and the rising demand for high-performance, environmentally friendly solutions.

Epoxy Acrylate, Urethane Acrylate, Polyester Acrylate, Acrylic Acrylate, Other in the UV Curable Oligomer - Global Market:

Epoxy acrylate, urethane acrylate, polyester acrylate, and acrylic acrylate are the primary types of UV curable oligomers, each offering distinct properties and advantages for various applications. Epoxy acrylates are known for their excellent adhesion, chemical resistance, and mechanical properties, making them ideal for coatings and adhesives in demanding environments. They are widely used in industries such as electronics, automotive, and construction, where durability and performance are critical. Urethane acrylates, on the other hand, are valued for their flexibility, toughness, and abrasion resistance. These oligomers are commonly used in applications requiring a balance of hardness and elasticity, such as in flexible packaging, automotive interiors, and protective coatings. Polyester acrylates offer good weatherability, chemical resistance, and cost-effectiveness, making them suitable for outdoor applications and general-purpose coatings. They are often used in the production of inks, varnishes, and coatings for wood and metal substrates. Acrylic acrylates are characterized by their excellent clarity, UV stability, and fast curing times. These oligomers are preferred in applications where optical clarity and color stability are important, such as in optical coatings, clear coatings, and graphic arts. Each type of oligomer can be further modified to enhance specific properties, such as hardness, flexibility, or adhesion, to meet the unique requirements of different applications. The choice of oligomer depends on factors such as the desired performance characteristics, application method, and end-use environment. As the demand for UV curable systems continues to grow, manufacturers are investing in research and development to create new oligomer chemistries that offer improved performance and sustainability. This includes the development of bio-based oligomers and the use of advanced polymerization techniques to enhance the properties of existing oligomers. The global market for UV curable oligomers is highly competitive, with numerous players offering a wide range of products to meet the diverse needs of end-users. Companies are focusing on expanding their product portfolios, improving production processes, and enhancing customer support to gain a competitive edge in the market. The increasing adoption of UV curable oligomers in emerging markets, coupled with the growing awareness of the benefits of UV curing technology, is expected to drive market growth in the coming years.

Low Energy Curing, High Energy Curing in the UV Curable Oligomer - Global Market:

UV curable oligomers are utilized in both low energy curing and high energy curing applications, each offering unique advantages and challenges. Low energy curing refers to the use of UV light sources that emit lower energy levels, such as LED UV lamps, to initiate the curing process. This approach is gaining popularity due to its energy efficiency, reduced heat generation, and longer lamp life compared to traditional mercury vapor lamps. Low energy curing is particularly beneficial for heat-sensitive substrates, such as plastics and thin films, where excessive heat can cause deformation or damage. The use of UV curable oligomers in low energy curing applications allows for rapid curing at lower temperatures, resulting in improved productivity and reduced energy costs. Additionally, the reduced heat output of LED UV lamps minimizes the risk of thermal degradation of the cured film, enhancing the overall quality and durability of the final product. High energy curing, on the other hand, involves the use of traditional UV lamps that emit higher energy levels, providing faster curing times and deeper penetration into thicker coatings or substrates. This approach is ideal for applications requiring high throughput and robust performance, such as in industrial coatings, automotive finishes, and electronic encapsulants. The use of UV curable oligomers in high energy curing applications ensures rapid curing and excellent adhesion, even on challenging substrates. However, the higher energy output of traditional UV lamps can generate significant heat, which may require additional cooling measures to prevent substrate damage. Despite this challenge, high energy curing remains a popular choice for applications where speed and performance are paramount. The versatility of UV curable oligomers allows them to be tailored for both low and high energy curing applications, providing manufacturers with the flexibility to choose the most suitable curing method for their specific needs. As the demand for energy-efficient and environmentally friendly curing technologies continues to rise, the adoption of UV curable oligomers in both low and high energy curing applications is expected to grow, driven by advancements in UV lamp technology and the development of new oligomer chemistries.

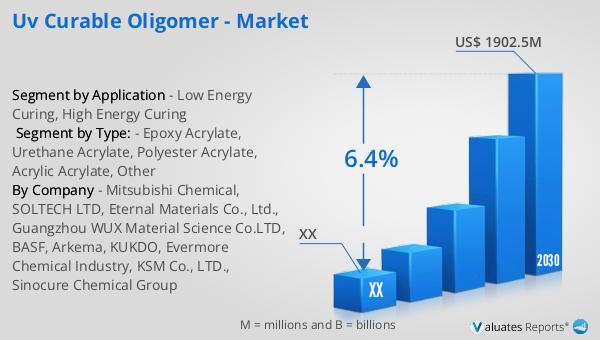

UV Curable Oligomer - Global Market Outlook:

The global market for UV curable oligomers was valued at approximately $1,237 million in 2023 and is projected to reach an adjusted size of $1,902.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.4% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for UV curable oligomers across various industries, driven by their superior performance characteristics and environmental benefits. The North American market, in particular, is expected to experience significant growth, although specific figures for this region were not provided. The anticipated expansion of the UV curable oligomer market is attributed to the rising adoption of UV curing technology, advancements in oligomer formulations, and the growing emphasis on sustainable and energy-efficient production processes. As industries continue to seek innovative solutions to enhance product performance and reduce environmental impact, the demand for UV curable oligomers is expected to rise, supported by ongoing research and development efforts and the increasing availability of raw materials. The market outlook for UV curable oligomers is positive, with significant growth opportunities anticipated in both established and emerging markets.

| Report Metric | Details |

| Report Name | UV Curable Oligomer - Market |

| Forecasted market size in 2030 | US$ 1902.5 million |

| CAGR | 6.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Mitsubishi Chemical, SOLTECH LTD, Eternal Materials Co., Ltd., Guangzhou WUX Material Science Co.LTD, BASF, Arkema, KUKDO, Evermore Chemical Industry, KSM Co., LTD., Sinocure Chemical Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |