What is Thermoplastic Vulcanizates Medical Grade - Global Market?

Thermoplastic Vulcanizates (TPVs) Medical Grade is a specialized segment within the global market that focuses on the production and application of TPVs for medical purposes. These materials are a type of thermoplastic elastomer, which means they combine the properties of rubber with the processability of plastics. This unique combination makes TPVs highly desirable in the medical field, where flexibility, durability, and biocompatibility are crucial. Medical-grade TPVs are used in a variety of applications, including medical tubing, seals, gaskets, and other components that require a high degree of precision and reliability. The global market for these materials is driven by the increasing demand for advanced medical devices and equipment, as well as the growing emphasis on patient safety and comfort. As healthcare systems around the world continue to evolve, the need for innovative materials like TPVs is expected to rise, making this a dynamic and rapidly expanding market. The versatility and adaptability of TPVs make them an ideal choice for manufacturers looking to meet the stringent requirements of the medical industry while also ensuring cost-effectiveness and efficiency in production.

35MED, 45MED, 55MED, 65MED, 75MED, 90MED in the Thermoplastic Vulcanizates Medical Grade - Global Market:

The Thermoplastic Vulcanizates Medical Grade market includes various grades such as 35MED, 45MED, 55MED, 65MED, 75MED, and 90MED, each offering distinct properties tailored to specific medical applications. The 35MED grade is known for its exceptional softness and flexibility, making it ideal for applications that require gentle contact with the skin, such as medical tubing and catheters. Its low durometer rating ensures that it can conform to delicate surfaces without causing irritation or discomfort. Moving up the scale, the 45MED grade offers a balance between flexibility and strength, making it suitable for applications that require a bit more structural integrity, such as seals and gaskets in medical devices. This grade is often used in applications where a moderate level of flexibility is needed without compromising on durability. The 55MED grade provides a higher level of rigidity while still maintaining some degree of flexibility. This makes it ideal for components that need to withstand more pressure or stress, such as connectors and fittings in medical equipment. Its enhanced durability ensures that it can perform reliably under demanding conditions. The 65MED grade is designed for applications that require even greater strength and resistance to wear and tear. This grade is often used in parts that are subject to frequent use or movement, such as hinges and joints in medical devices. Its robust nature ensures that it can withstand repeated stress without degrading over time. The 75MED grade offers a high level of rigidity and is often used in applications where maximum strength is required, such as structural components in medical equipment. Its ability to maintain its shape and integrity under heavy loads makes it a popular choice for demanding applications. Finally, the 90MED grade is the most rigid of the TPV medical grades, offering exceptional strength and durability. This grade is typically used in applications that require the highest level of structural integrity, such as support frames and housings in medical devices. Its superior performance under extreme conditions makes it an invaluable material for critical applications. Each of these grades is engineered to meet specific requirements, ensuring that manufacturers can select the most appropriate material for their needs. The versatility of TPVs allows for a wide range of applications, making them an essential component in the development of advanced medical devices and equipment. As the demand for innovative medical solutions continues to grow, the importance of selecting the right TPV grade becomes increasingly critical, ensuring that products meet the highest standards of safety, performance, and reliability.

Hospital, Laboratories, Research Institutes, Others in the Thermoplastic Vulcanizates Medical Grade - Global Market:

Thermoplastic Vulcanizates Medical Grade materials are extensively used in various sectors, including hospitals, laboratories, research institutes, and other medical facilities. In hospitals, these materials are crucial for the production of medical tubing, which is used in a wide range of applications such as intravenous (IV) lines, catheters, and respiratory equipment. The flexibility and biocompatibility of TPVs make them ideal for these applications, as they can be easily sterilized and do not cause adverse reactions when in contact with the human body. Additionally, TPVs are used in the production of seals and gaskets for medical devices, ensuring that they remain airtight and leak-proof, which is essential for maintaining the sterility and functionality of the equipment. In laboratories, TPVs are used in the production of various components such as pipette tips, test tube caps, and other laboratory equipment that require a high degree of precision and reliability. The durability and chemical resistance of TPVs make them suitable for use in environments where they may be exposed to harsh chemicals or repeated sterilization processes. Research institutes also rely on TPVs for the development of new medical devices and technologies. The versatility of these materials allows researchers to create prototypes and test new designs quickly and efficiently, accelerating the development process and bringing innovative solutions to market faster. In addition to these applications, TPVs are also used in other areas such as dental equipment, surgical instruments, and orthopedic devices. Their ability to be molded into complex shapes and their resistance to wear and tear make them an ideal choice for these applications, where precision and durability are paramount. Overall, the use of Thermoplastic Vulcanizates Medical Grade materials in these various sectors highlights their importance in the medical industry. Their unique properties and versatility make them an essential component in the development and production of advanced medical devices and equipment, ensuring that healthcare providers can deliver the highest level of care to their patients. As the demand for innovative medical solutions continues to grow, the role of TPVs in the medical field is expected to expand, driving further advancements in healthcare technology.

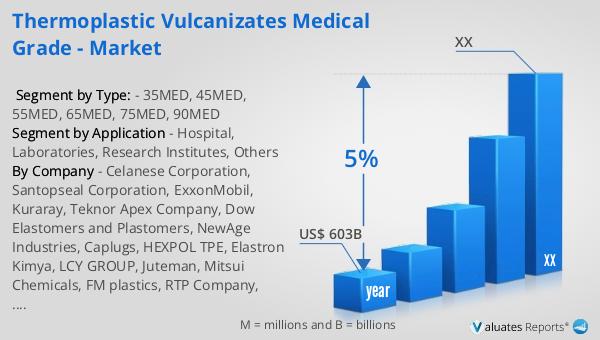

Thermoplastic Vulcanizates Medical Grade - Global Market Outlook:

Based on our analysis, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is indicative of the increasing demand for advanced medical technologies and innovations across the globe. The medical device industry is a critical component of the healthcare sector, providing essential tools and equipment that facilitate diagnosis, treatment, and patient care. The projected growth rate reflects the ongoing advancements in medical technology, as well as the rising prevalence of chronic diseases and an aging population that requires more comprehensive healthcare solutions. As healthcare systems worldwide strive to improve patient outcomes and reduce costs, the demand for efficient and effective medical devices is expected to rise. This growth is also driven by the increasing adoption of digital health technologies, which are transforming the way healthcare is delivered and managed. The integration of artificial intelligence, telemedicine, and wearable devices into healthcare systems is creating new opportunities for innovation and expansion within the medical device market. As a result, companies operating in this space are investing heavily in research and development to bring new and improved products to market, further fueling the growth of the industry. The global market for medical devices is poised for significant expansion in the coming years, driven by a combination of technological advancements, demographic shifts, and evolving healthcare needs.

| Report Metric | Details |

| Report Name | Thermoplastic Vulcanizates Medical Grade - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Celanese Corporation, Santopseal Corporation, ExxonMobil, Kuraray, Teknor Apex Company, Dow Elastomers and Plastomers, NewAge Industries, Caplugs, HEXPOL TPE, Elastron Kimya, LCY GROUP, Juteman, Mitsui Chemicals, FM plastics, RTP Company, Mexichem Specialty Compounds, Preferred Plastics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |