What is Single-use Tangential Flow Filtration (TFF) Systems - Global Market?

Single-use Tangential Flow Filtration (TFF) systems are a pivotal innovation in the field of filtration technology, particularly within the biopharmaceutical industry. These systems are designed to separate and purify biomolecules, such as proteins, from complex mixtures. Unlike traditional filtration methods, TFF systems allow the fluid to flow tangentially across the filter surface, minimizing clogging and enhancing efficiency. The "single-use" aspect refers to the disposable nature of the components that come into contact with the product, which significantly reduces the risk of cross-contamination and the need for extensive cleaning and validation processes. This feature is particularly advantageous in environments where sterility and speed are critical, such as in the production of vaccines and other biopharmaceuticals. The global market for these systems is expanding as more companies recognize the benefits of flexibility, reduced downtime, and cost-effectiveness that single-use TFF systems offer. As the demand for biopharmaceuticals continues to rise, driven by an aging population and the increasing prevalence of chronic diseases, the adoption of single-use TFF systems is expected to grow, making them a crucial component in modern bioprocessing.

Below 200L, 200-500L, Above 500L in the Single-use Tangential Flow Filtration (TFF) Systems - Global Market:

In the global market for Single-use Tangential Flow Filtration (TFF) systems, the capacity of the systems plays a significant role in determining their application and utility. Systems with a capacity below 200 liters are typically used in laboratory settings or for small-scale production. These systems are ideal for research and development purposes, where flexibility and ease of use are paramount. They allow researchers to quickly test and refine processes without the need for extensive setup or cleanup. The compact size and single-use nature of these systems make them particularly attractive for labs that handle multiple projects or need to switch between different processes rapidly. On the other hand, systems with a capacity between 200 and 500 liters are often employed in pilot-scale production or for niche biopharmaceutical manufacturing. These systems strike a balance between the agility of smaller systems and the throughput required for larger production runs. They are suitable for producing batches of specialized products or for scaling up processes that have been developed in the lab. The ability to handle moderate volumes makes these systems versatile, allowing manufacturers to respond quickly to changes in demand or to produce limited quantities of high-value products. For large-scale production, systems with a capacity above 500 liters are essential. These systems are designed to handle the high volumes required for commercial manufacturing of biopharmaceuticals. They offer the efficiency and robustness needed to produce large batches consistently and reliably. The single-use nature of these systems is particularly beneficial in large-scale operations, as it reduces the time and cost associated with cleaning and validation, allowing manufacturers to maintain high levels of productivity. As the biopharmaceutical industry continues to grow, driven by advances in biotechnology and increasing demand for biologics, the need for efficient and scalable filtration solutions is more critical than ever. Single-use TFF systems, with their range of capacities, provide the flexibility and efficiency needed to meet the diverse needs of the industry, from small-scale research to large-scale production.

Laboratory, Biopharmaceutical Manufacturers, Others in the Single-use Tangential Flow Filtration (TFF) Systems - Global Market:

Single-use Tangential Flow Filtration (TFF) systems are utilized across various sectors, each with unique requirements and benefits. In laboratory settings, these systems are invaluable for research and development. Laboratories often deal with small volumes and require systems that are easy to set up and operate. The single-use nature of TFF systems means that researchers can quickly switch between different experiments without worrying about cross-contamination or the time-consuming cleaning processes associated with traditional systems. This flexibility is crucial in a research environment where time and resources are often limited. Moreover, the ability to rapidly test and refine processes accelerates the development of new products, making single-use TFF systems a vital tool in the innovation pipeline. In the realm of biopharmaceutical manufacturing, single-use TFF systems are increasingly being adopted for both pilot and full-scale production. The biopharmaceutical industry is characterized by its stringent regulatory requirements and the need for high levels of sterility and precision. Single-use systems help manufacturers meet these demands by reducing the risk of contamination and simplifying compliance with regulatory standards. The disposable components eliminate the need for extensive cleaning and validation, which not only saves time but also reduces the risk of human error. This is particularly important in the production of biologics, where even minor contamination can have significant consequences. Additionally, the scalability of single-use TFF systems allows manufacturers to adjust production volumes quickly in response to market demands, providing a competitive edge in a rapidly evolving industry. Beyond laboratories and biopharmaceutical manufacturers, single-use TFF systems find applications in other areas such as food and beverage processing, water treatment, and chemical manufacturing. In these industries, the systems are used to purify and concentrate products, ensuring quality and consistency. The single-use aspect is particularly beneficial in industries where product changeover is frequent, as it minimizes downtime and maximizes productivity. Furthermore, the reduced need for cleaning chemicals and water aligns with sustainability goals, making single-use TFF systems an attractive option for companies looking to reduce their environmental footprint. Overall, the versatility and efficiency of single-use TFF systems make them a valuable asset across a wide range of applications, driving their adoption in the global market.

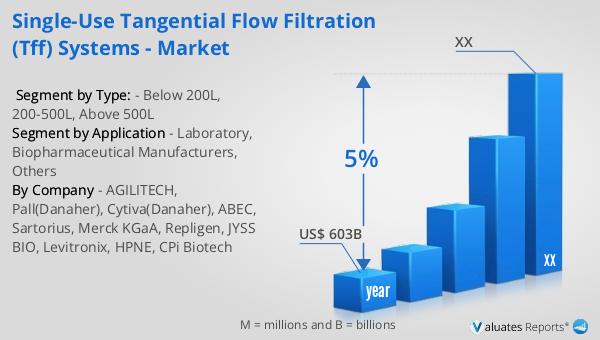

Single-use Tangential Flow Filtration (TFF) Systems - Global Market Outlook:

Our analysis indicates that the worldwide market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years.

| Report Metric | Details |

| Report Name | Single-use Tangential Flow Filtration (TFF) Systems - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | AGILITECH, Pall(Danaher), Cytiva(Danaher), ABEC, Sartorius, Merck KGaA, Repligen, JYSS BIO, Levitronix, HPNE, CPi Biotech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |