What is Robotic Welding System - Global Market?

The Robotic Welding System - Global Market refers to the worldwide industry focused on the development, production, and application of robotic systems specifically designed for welding tasks. These systems are increasingly being adopted across various industries due to their ability to enhance precision, efficiency, and safety in welding operations. Robotic welding systems consist of several components, including welding robots, controllers, positioners, and sensors, all working together to automate the welding process. The global market for these systems is driven by the growing demand for automation in manufacturing processes, the need for high-quality welds, and the shortage of skilled labor in the welding industry. As industries continue to seek ways to improve productivity and reduce operational costs, the adoption of robotic welding systems is expected to rise. This market encompasses a wide range of applications, from automotive and aerospace to construction and heavy machinery, highlighting the versatility and importance of robotic welding in modern manufacturing. The market is characterized by continuous technological advancements, with companies investing in research and development to enhance the capabilities and efficiency of robotic welding systems. As a result, the global market for robotic welding systems is poised for significant growth in the coming years.

Welding Robot, Welding Positioner, Robot Controller, Welding Peripherals, Welding Sensors, Others in the Robotic Welding System - Global Market:

Robotic welding systems are composed of several key components that work together to automate the welding process. The welding robot is the central element, responsible for executing the welding tasks with precision and consistency. These robots are equipped with advanced software and hardware that allow them to perform complex welding operations with minimal human intervention. Welding positioners are another crucial component, designed to hold and manipulate the workpiece in the optimal position for welding. This ensures that the welding robot can access all necessary areas of the workpiece, resulting in high-quality welds. The robot controller acts as the brain of the system, coordinating the movements and actions of the welding robot and positioner. It processes input from various sensors and peripherals to ensure that the welding process is executed accurately and efficiently. Welding peripherals, such as torches, wire feeders, and gas regulators, are essential for delivering the necessary materials and conditions for welding. These peripherals are integrated into the robotic system to ensure seamless operation and high-quality welds. Welding sensors play a critical role in monitoring the welding process, providing real-time feedback to the robot controller. These sensors detect parameters such as temperature, arc length, and weld pool size, allowing the system to make adjustments as needed to maintain optimal welding conditions. Other components, such as safety systems and software interfaces, are also integral to the operation of robotic welding systems. Safety systems ensure that the welding process is conducted safely, protecting both the equipment and operators from potential hazards. Software interfaces provide a user-friendly platform for programming and controlling the robotic system, allowing operators to easily set up and manage welding tasks. Together, these components form a comprehensive robotic welding system that enhances productivity, quality, and safety in welding operations.

Automotive, Aerospace, Mechanical, Others in the Robotic Welding System - Global Market:

Robotic welding systems are widely used across various industries, each benefiting from the automation and precision these systems offer. In the automotive industry, robotic welding systems are essential for manufacturing processes, where they are used to assemble car bodies, frames, and other components. The high precision and speed of robotic welding systems ensure that automotive manufacturers can produce vehicles with consistent quality and reduced production times. In the aerospace industry, robotic welding systems are used to fabricate and assemble aircraft components, where precision and reliability are paramount. The ability of robotic systems to perform complex welds with high accuracy makes them ideal for aerospace applications, where even minor defects can have significant consequences. In the mechanical industry, robotic welding systems are employed in the production of machinery and equipment, where they help improve the quality and durability of welded joints. The automation provided by robotic systems allows manufacturers to produce complex assemblies with minimal human intervention, reducing labor costs and increasing efficiency. Other industries, such as construction and shipbuilding, also benefit from the use of robotic welding systems. In construction, these systems are used to fabricate steel structures and components, where their ability to perform precise and consistent welds is highly valued. In shipbuilding, robotic welding systems are used to assemble large sections of ships, where their speed and accuracy help reduce production times and improve the overall quality of the vessels. Overall, the versatility and efficiency of robotic welding systems make them an invaluable tool across a wide range of industries, driving their adoption and growth in the global market.

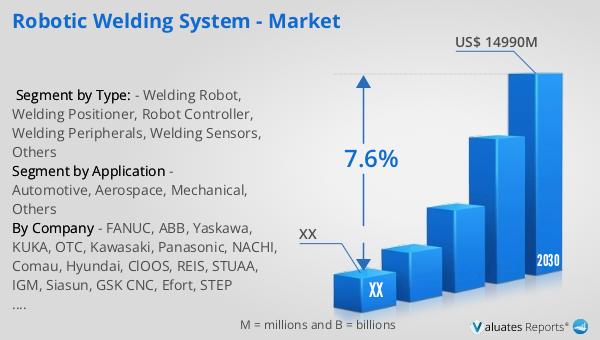

Robotic Welding System - Global Market Outlook:

The global market for Robotic Welding Systems was valued at approximately US$ 8,885.1 million in 2023. It is projected to grow significantly, reaching an estimated size of US$ 14,990 million by 2030, with a compound annual growth rate (CAGR) of 7.6% during the forecast period from 2024 to 2030. In 2019, the top five players in the market accounted for 38% of the global robotic welding revenue market share, indicating a competitive landscape with a few dominant players. The automotive and transportation segment was identified as the largest market segment, holding a substantial 36% market share in 2019. This highlights the critical role of robotic welding systems in the automotive industry, where they are used extensively for assembling vehicle components and structures. The growth of the global market for robotic welding systems is driven by the increasing demand for automation in manufacturing processes, the need for high-quality welds, and the shortage of skilled labor in the welding industry. As industries continue to seek ways to improve productivity and reduce operational costs, the adoption of robotic welding systems is expected to rise, further fueling market growth.

| Report Metric | Details |

| Report Name | Robotic Welding System - Market |

| Forecasted market size in 2030 | US$ 14990 million |

| CAGR | 7.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | FANUC, ABB, Yaskawa, KUKA, OTC, Kawasaki, Panasonic, NACHI, Comau, Hyundai, ClOOS, REIS, STUAA, IGM, Siasun, GSK CNC, Efort, STEP Electric, PeiTian, Lincoln Electric |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |