What is Reinforced Thermoplastic Pipes - Global Market?

Reinforced Thermoplastic Pipes (RTP) are a type of flexible pipe used in various industries, primarily for transporting fluids and gases. These pipes are constructed using multiple layers of thermoplastic materials, reinforced with high-strength fibers, which provide them with exceptional durability and flexibility. The global market for RTPs is expanding due to their advantages over traditional metal pipes, such as corrosion resistance, ease of installation, and lower maintenance costs. RTPs are particularly popular in industries like oil and gas, where they are used for transporting hydrocarbons, as well as in water and chemical industries. The demand for RTPs is driven by the need for efficient and reliable piping solutions that can withstand harsh environmental conditions and high pressures. As industries continue to seek sustainable and cost-effective alternatives to conventional piping systems, the market for reinforced thermoplastic pipes is expected to grow steadily. The versatility and adaptability of RTPs make them an attractive choice for a wide range of applications, contributing to their increasing adoption across the globe.

PVC, PE, PP, PPR, Others in the Reinforced Thermoplastic Pipes - Global Market:

Reinforced Thermoplastic Pipes are made using various types of thermoplastic materials, each offering unique properties that cater to specific applications. Polyvinyl Chloride (PVC) is one of the most commonly used materials in RTP manufacturing. PVC is known for its excellent chemical resistance, making it suitable for transporting a wide range of fluids, including corrosive chemicals. It is also lightweight and easy to handle, which simplifies the installation process. However, PVC has limitations in terms of temperature resistance, which can restrict its use in high-temperature applications. Polyethylene (PE) is another popular material used in RTPs. It is highly flexible and resistant to impact, making it ideal for applications where the pipes need to withstand mechanical stress. PE is also resistant to a wide range of chemicals, which enhances its versatility. However, like PVC, PE has limitations in terms of temperature resistance. Polypropylene (PP) is used in RTPs for its excellent chemical resistance and ability to withstand higher temperatures compared to PVC and PE. PP is also lightweight and offers good mechanical properties, making it suitable for a variety of applications. However, it is more expensive than PVC and PE, which can be a consideration for cost-sensitive projects. Polypropylene Random Copolymer (PPR) is a variant of PP that offers improved impact resistance and flexibility. PPR is often used in applications where the pipes need to withstand frequent temperature fluctuations and mechanical stress. It is also resistant to a wide range of chemicals, making it suitable for transporting various fluids. Other materials used in RTPs include polyamide and polyvinylidene fluoride, which offer unique properties such as high temperature resistance and excellent chemical resistance. These materials are often used in specialized applications where standard thermoplastics may not perform adequately. The choice of material for RTPs depends on the specific requirements of the application, including the type of fluid being transported, the operating temperature, and the mechanical stresses the pipes will be subjected to. Each material offers a unique set of properties that can be tailored to meet the needs of different industries and applications.

Energy, Chemical Industry, Others in the Reinforced Thermoplastic Pipes - Global Market:

Reinforced Thermoplastic Pipes are widely used in the energy sector, particularly in the oil and gas industry. Their flexibility and corrosion resistance make them ideal for transporting hydrocarbons over long distances, both onshore and offshore. RTPs can withstand high pressures and harsh environmental conditions, which are common in oil and gas operations. They are also used in the construction of pipelines for transporting natural gas, where their ability to handle high pressures and resist chemical corrosion is crucial. In the chemical industry, RTPs are used for transporting a wide range of chemicals, including acids, bases, and solvents. Their excellent chemical resistance ensures that they can safely transport corrosive substances without degrading or leaking. RTPs are also used in the construction of chemical processing plants, where their flexibility and ease of installation make them an attractive choice for complex piping systems. In addition to the energy and chemical industries, RTPs are used in various other applications, including water distribution and wastewater management. Their corrosion resistance and durability make them suitable for transporting potable water, as well as for use in sewage systems. RTPs are also used in the construction of irrigation systems, where their flexibility and resistance to environmental stressors make them ideal for use in agricultural settings. The versatility of RTPs allows them to be used in a wide range of applications, making them an attractive choice for industries seeking reliable and cost-effective piping solutions. As industries continue to seek sustainable and efficient alternatives to traditional piping systems, the demand for reinforced thermoplastic pipes is expected to grow. Their ability to withstand harsh conditions and transport a variety of fluids makes them an essential component in many industrial applications.

Reinforced Thermoplastic Pipes - Global Market Outlook:

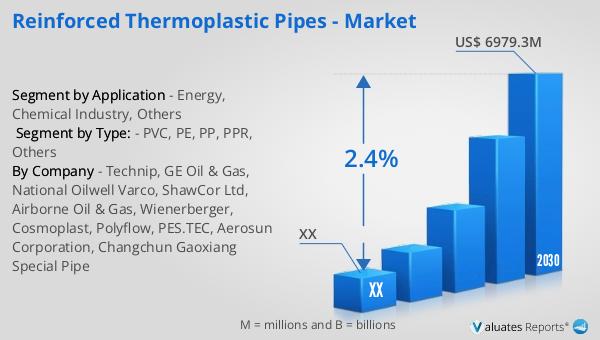

The global market for Reinforced Thermoplastic Pipes was valued at approximately US$ 5,891 million in 2023. It is projected to reach a revised size of around US$ 6,979.3 million by 2030, growing at a compound annual growth rate (CAGR) of 2.4% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for efficient and reliable piping solutions across various industries. The market is highly competitive, with the top three players accounting for about 82% of the global market share. This concentration of market power indicates a strong presence of leading companies that dominate the industry. These companies have established themselves as key players by offering high-quality products and innovative solutions that meet the evolving needs of their customers. As the market continues to grow, these companies are likely to maintain their competitive edge by investing in research and development, expanding their product portfolios, and exploring new market opportunities. The global market for reinforced thermoplastic pipes is poised for steady growth, driven by the increasing demand for sustainable and cost-effective piping solutions.

| Report Metric | Details |

| Report Name | Reinforced Thermoplastic Pipes - Market |

| Forecasted market size in 2030 | US$ 6979.3 million |

| CAGR | 2.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Technip, GE Oil & Gas, National Oilwell Varco, ShawCor Ltd, Airborne Oil & Gas, Wienerberger, Cosmoplast, Polyflow, PES.TEC, Aerosun Corporation, Changchun Gaoxiang Special Pipe |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |