What is Nuclear & Defense Grade Boron Carbide - Global Market?

Nuclear and defense grade boron carbide is a specialized material that plays a crucial role in various high-stakes industries. Known for its exceptional hardness and low density, boron carbide is one of the hardest materials available, only surpassed by diamond and cubic boron nitride. This makes it an ideal choice for applications requiring high durability and resistance to wear and impact. In the nuclear sector, boron carbide is primarily used as a neutron absorber in control rods, which are essential for regulating nuclear reactions in reactors. Its ability to absorb neutrons without forming long-lived radioactive isotopes makes it invaluable for maintaining safety and efficiency in nuclear power plants. In the defense industry, boron carbide is utilized in the production of lightweight armor and protective gear, offering superior protection against ballistic threats while minimizing the weight burden on personnel and vehicles. The global market for nuclear and defense grade boron carbide is driven by the increasing demand for advanced materials that can enhance safety and performance in these critical sectors. As technology continues to evolve, the applications and importance of boron carbide are expected to expand, further solidifying its role as a key material in the nuclear and defense industries.

Powder, Paste, Grains in the Nuclear & Defense Grade Boron Carbide - Global Market:

Boron carbide is available in various forms, including powder, paste, and grains, each serving distinct purposes in the nuclear and defense sectors. The powder form of boron carbide is widely used in the production of control rods for nuclear reactors. Its fine particle size allows for precise mixing and compaction, ensuring uniform distribution within the control rod matrix. This uniformity is crucial for the effective absorption of neutrons, which is essential for maintaining the stability and safety of nuclear reactions. Additionally, boron carbide powder is used in the manufacturing of neutron shielding materials, which protect personnel and equipment from harmful radiation exposure. The paste form of boron carbide is often employed in polishing and lapping applications, where its abrasive properties are utilized to achieve smooth and precise surfaces. In the defense industry, boron carbide paste is used in the production of lightweight armor systems, providing enhanced protection against ballistic threats. The paste's ability to be molded and shaped allows for the creation of complex armor designs that offer maximum coverage and protection. Boron carbide grains, on the other hand, are used in the production of abrasive tools and cutting applications. Their hardness and durability make them ideal for cutting and grinding operations, where they can withstand high levels of stress and wear. In the nuclear industry, boron carbide grains are used in the production of neutron detectors, which are essential for monitoring and controlling nuclear reactions. The grains' ability to absorb neutrons makes them an effective component in these critical devices. Overall, the versatility of boron carbide in its various forms makes it an indispensable material in the nuclear and defense sectors, where its unique properties are leveraged to enhance safety, performance, and efficiency. As the demand for advanced materials continues to grow, the market for boron carbide is expected to expand, driven by its wide range of applications and the ongoing need for innovative solutions in these high-stakes industries.

Nuclear, Defense in the Nuclear & Defense Grade Boron Carbide - Global Market:

In the nuclear industry, nuclear and defense grade boron carbide is primarily used as a neutron absorber in control rods, which are critical components of nuclear reactors. Control rods are inserted into the reactor core to regulate the fission process by absorbing excess neutrons, thereby controlling the rate of the nuclear reaction. Boron carbide's high neutron absorption cross-section and stability under high temperatures make it an ideal material for this application. Its ability to absorb neutrons without forming long-lived radioactive isotopes ensures the safe and efficient operation of nuclear reactors. Additionally, boron carbide is used in the production of neutron shielding materials, which protect personnel and equipment from harmful radiation exposure. These materials are essential for maintaining safety in nuclear facilities, where radiation levels must be carefully controlled to prevent health risks. In the defense sector, boron carbide is utilized in the production of lightweight armor and protective gear. Its exceptional hardness and low density make it an ideal material for ballistic protection, offering superior resistance to impact and penetration while minimizing the weight burden on personnel and vehicles. Boron carbide armor is used in a variety of applications, including body armor for military personnel, vehicle armor for military vehicles, and protective gear for law enforcement officers. The material's ability to withstand high levels of stress and impact makes it an effective solution for protecting against ballistic threats, ensuring the safety and security of those in high-risk environments. Furthermore, boron carbide is used in the production of cutting tools and abrasive materials, where its hardness and durability are leveraged to achieve precise and efficient cutting and grinding operations. In both the nuclear and defense industries, the unique properties of boron carbide make it an indispensable material, providing critical solutions for enhancing safety, performance, and efficiency. As technology continues to advance, the applications and importance of boron carbide are expected to grow, further solidifying its role as a key material in these high-stakes sectors.

Nuclear & Defense Grade Boron Carbide - Global Market Outlook:

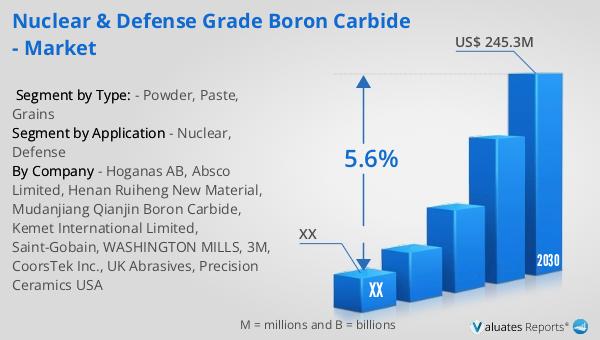

The global market for nuclear and defense grade boron carbide was valued at approximately $168.3 million in 2023. It is projected to grow to a revised size of $245.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.6% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for advanced materials that can enhance safety and performance in the nuclear and defense sectors. In North America, the market for nuclear and defense grade boron carbide was valued at $ million in 2023 and is expected to reach $ million by 2030, with a CAGR of % during the forecast period from 2024 through 2030. The growth in this region is attributed to the ongoing advancements in technology and the increasing need for innovative solutions in high-stakes industries. As the demand for boron carbide continues to rise, the market is expected to expand, driven by its wide range of applications and the ongoing need for advanced materials in the nuclear and defense sectors. The unique properties of boron carbide, including its exceptional hardness, low density, and high neutron absorption cross-section, make it an indispensable material in these critical industries, where safety and performance are of utmost importance.

| Report Metric | Details |

| Report Name | Nuclear & Defense Grade Boron Carbide - Market |

| Forecasted market size in 2030 | US$ 245.3 million |

| CAGR | 5.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hoganas AB, Absco Limited, Henan Ruiheng New Material, Mudanjiang Qianjin Boron Carbide, Kemet International Limited, Saint-Gobain, WASHINGTON MILLS, 3M, CoorsTek Inc., UK Abrasives, Precision Ceramics USA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |