What is High Precision Centerless Grinders - Global Market?

High precision centerless grinders are specialized machines used in the manufacturing industry to achieve high levels of precision and accuracy in the grinding process. Unlike traditional grinding machines, centerless grinders do not require the workpiece to be held in place by a spindle or fixture. Instead, the workpiece is supported by a blade and guided between a grinding wheel and a regulating wheel. This setup allows for continuous grinding of cylindrical parts, making it highly efficient for mass production. The global market for high precision centerless grinders is driven by the demand for high-quality components in various industries such as automotive, aerospace, and medical. These machines are essential for producing parts with tight tolerances and smooth finishes, which are critical in applications where precision is paramount. As industries continue to push for higher standards of quality and efficiency, the demand for advanced grinding solutions like high precision centerless grinders is expected to grow. The market is characterized by technological advancements, with manufacturers focusing on automation and integration of smart technologies to enhance productivity and reduce operational costs.

Universal Type, Special Type, Precise Type in the High Precision Centerless Grinders - Global Market:

High precision centerless grinders are categorized into three main types: Universal Type, Special Type, and Precise Type, each serving distinct purposes in the global market. Universal Type grinders are versatile machines designed to handle a wide range of grinding tasks. They are equipped with adjustable features that allow them to accommodate different sizes and shapes of workpieces, making them ideal for industries that require flexibility in production. These grinders are commonly used in workshops and factories where multiple types of components are manufactured. On the other hand, Special Type grinders are tailored for specific applications. They are engineered to meet the unique requirements of particular industries or products. For instance, some special type grinders are designed for grinding complex geometries or materials that are difficult to machine. These machines are often custom-built to ensure they deliver the desired precision and efficiency for specialized tasks. Precise Type grinders, as the name suggests, are focused on achieving the highest levels of accuracy and precision. They are used in applications where even the slightest deviation in dimensions can lead to significant issues. These grinders are equipped with advanced features such as high-resolution sensors and computer-controlled systems to ensure that the grinding process is as accurate as possible. In the global market, the demand for each type of grinder varies based on the specific needs of different industries. Universal Type grinders are popular in sectors where versatility is crucial, while Special Type grinders are sought after in industries with unique grinding requirements. Precise Type grinders are in high demand in fields where precision is non-negotiable, such as aerospace and medical device manufacturing. As technology continues to evolve, manufacturers are investing in research and development to enhance the capabilities of these machines, ensuring they meet the ever-increasing demands of modern manufacturing.

Automobile, Aerospace, Engineering Machinery, Medical, Others in the High Precision Centerless Grinders - Global Market:

High precision centerless grinders play a crucial role in various industries, including automobile, aerospace, engineering machinery, medical, and others, by providing the precision and efficiency needed for high-quality production. In the automobile industry, these grinders are used to manufacture components such as camshafts, crankshafts, and transmission parts. The ability to produce parts with tight tolerances and smooth finishes is essential for ensuring the performance and reliability of vehicles. In the aerospace sector, high precision centerless grinders are used to produce critical components such as turbine blades, landing gear parts, and engine components. The stringent quality standards in this industry demand the highest levels of precision, making these grinders indispensable. In engineering machinery, centerless grinders are used to produce parts for heavy machinery and equipment. The durability and precision of these components are vital for the efficient operation of machinery used in construction, mining, and other industrial applications. In the medical field, high precision centerless grinders are used to manufacture components for medical devices and implants. The precision and accuracy of these parts are crucial for ensuring the safety and effectiveness of medical treatments. Other industries that benefit from high precision centerless grinders include electronics, where they are used to produce components for consumer electronics and communication devices. The versatility and efficiency of these grinders make them valuable assets in any industry that requires high-quality, precision-engineered components. As technology advances, the capabilities of high precision centerless grinders continue to improve, enabling manufacturers to meet the ever-increasing demands of modern production.

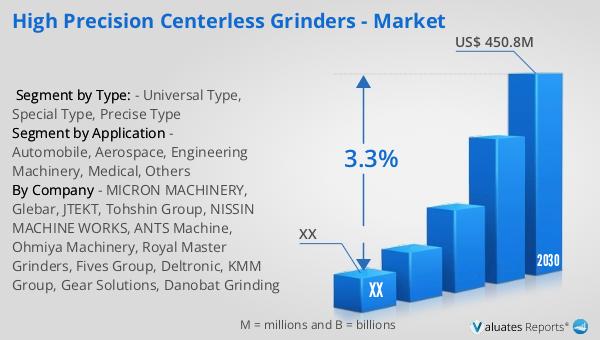

High Precision Centerless Grinders - Global Market Outlook:

The global market for high precision centerless grinders was valued at approximately US$ 360 million in 2023. It is projected to grow to a revised size of US$ 450.8 million by 2030, with a compound annual growth rate (CAGR) of 3.3% during the forecast period from 2024 to 2030. This growth is driven by the increasing adoption of advanced automation and robotics in the high precision centerless grinding market. Automation technologies are being integrated into these machines to enhance productivity, reduce human error, and improve the overall efficiency of the grinding process. Robotics, in particular, is playing a significant role in automating the loading and unloading of workpieces, allowing for continuous operation and minimizing downtime. The integration of smart technologies, such as sensors and data analytics, is also contributing to the growth of the market by enabling real-time monitoring and optimization of the grinding process. These advancements are helping manufacturers meet the growing demand for high-quality components in various industries while reducing operational costs and improving competitiveness. As the market continues to evolve, the focus on automation and smart technologies is expected to drive further innovation and growth in the high precision centerless grinders market.

| Report Metric | Details |

| Report Name | High Precision Centerless Grinders - Market |

| Forecasted market size in 2030 | US$ 450.8 million |

| CAGR | 3.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | MICRON MACHINERY, Glebar, JTEKT, Tohshin Group, NISSIN MACHINE WORKS, ANTS Machine, Ohmiya Machinery, Royal Master Grinders, Fives Group, Deltronic, KMM Group, Gear Solutions, Danobat Grinding |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |