What is High Performance Neodymium Iron Boron Magnets - Global Market?

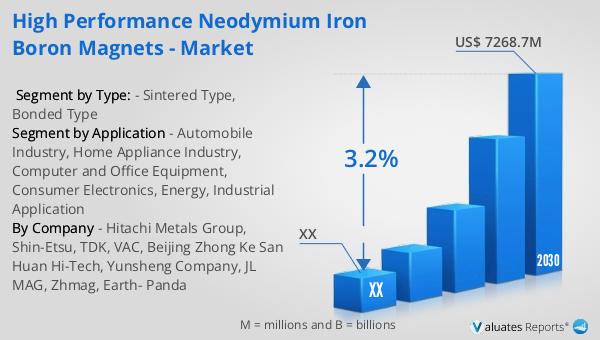

High Performance Neodymium Iron Boron Magnets, often abbreviated as NdFeB magnets, are a type of rare earth magnet that stands out due to their exceptional magnetic strength. These magnets are composed primarily of neodymium, iron, and boron, which together create a powerful magnetic field. They are widely recognized for their superior performance compared to other types of magnets, making them highly sought after in various industries. The global market for these magnets is driven by their extensive applications, ranging from consumer electronics to industrial machinery. Their ability to maintain a strong magnetic field even at high temperatures makes them ideal for use in demanding environments. As industries continue to innovate and seek more efficient technologies, the demand for high-performance NdFeB magnets is expected to grow. This growth is further fueled by advancements in manufacturing processes that enhance the quality and performance of these magnets, making them more accessible and affordable for a broader range of applications. The global market for High Performance Neodymium Iron Boron Magnets was valued at approximately US$ 5836 million in 2023, with projections indicating a rise to US$ 7268.7 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.2% during the forecast period from 2024 to 2030. This steady growth underscores the increasing reliance on these magnets across various sectors, highlighting their critical role in modern technology and industry.

Sintered Type, Bonded Type in the High Performance Neodymium Iron Boron Magnets - Global Market:

High Performance Neodymium Iron Boron Magnets are available in two primary types: sintered and bonded. Sintered NdFeB magnets are created through a process that involves compressing fine NdFeB powder into a dense form, which is then heated to a temperature below its melting point. This process results in a solid, robust magnet with high magnetic strength and excellent thermal stability. Sintered magnets are known for their superior magnetic properties, making them ideal for applications that require strong and consistent magnetic fields. They are commonly used in electric motors, generators, and other high-performance applications where durability and reliability are paramount. On the other hand, bonded NdFeB magnets are produced by combining NdFeB powder with a binding agent, such as plastic or resin, and then forming the mixture into the desired shape. This process allows for greater flexibility in design and the production of complex shapes that would be difficult to achieve with sintered magnets. Bonded magnets are generally less powerful than their sintered counterparts but offer advantages in terms of cost-effectiveness and ease of manufacturing. They are often used in applications where precise shapes and sizes are required, such as in sensors, small motors, and electronic devices. The choice between sintered and bonded NdFeB magnets depends largely on the specific requirements of the application, including factors such as magnetic strength, thermal stability, cost, and design flexibility. As the global market for High Performance Neodymium Iron Boron Magnets continues to expand, both sintered and bonded types are expected to play a crucial role in meeting the diverse needs of various industries. The ongoing development of new manufacturing techniques and materials is likely to further enhance the performance and versatility of these magnets, opening up new possibilities for their use in cutting-edge technologies.

Automobile Industry, Home Appliance Industry, Computer and Office Equipment, Consumer Electronics, Energy, Industrial Application in the High Performance Neodymium Iron Boron Magnets - Global Market:

High Performance Neodymium Iron Boron Magnets are integral to a wide range of applications across various industries, thanks to their exceptional magnetic properties. In the automobile industry, these magnets are used extensively in electric and hybrid vehicles, where they are a key component in electric motors and generators. Their ability to provide strong and efficient magnetic fields contributes to the overall performance and efficiency of these vehicles, making them an essential part of the push towards more sustainable transportation solutions. In the home appliance industry, NdFeB magnets are found in a variety of products, including refrigerators, washing machines, and air conditioners. They are used in motors and compressors, where their high magnetic strength and reliability help improve the efficiency and performance of these appliances. In the realm of computer and office equipment, these magnets are used in hard disk drives, printers, and other devices that require precise and reliable magnetic fields. Their small size and high strength make them ideal for use in compact and high-performance electronic devices. Consumer electronics also benefit from the use of NdFeB magnets, with applications ranging from speakers and headphones to smartphones and tablets. Their ability to produce clear and powerful sound makes them a popular choice for audio equipment, while their compact size and strength are ideal for use in portable electronic devices. In the energy sector, NdFeB magnets are used in wind turbines and other renewable energy technologies, where their high efficiency and reliability help maximize energy output. Finally, in industrial applications, these magnets are used in a variety of machinery and equipment, including magnetic separators, lifting devices, and sensors. Their versatility and performance make them a valuable component in many industrial processes, contributing to increased efficiency and productivity. As the demand for high-performance technologies continues to grow, the use of High Performance Neodymium Iron Boron Magnets is expected to expand across these and other industries, driving innovation and progress in a wide range of applications.

High Performance Neodymium Iron Boron Magnets - Global Market Outlook:

The global market for High Performance Neodymium Iron Boron Magnets was valued at approximately US$ 5836 million in 2023, with expectations for it to grow to a revised size of US$ 7268.7 million by 2030. This growth represents a compound annual growth rate (CAGR) of 3.2% during the forecast period from 2024 to 2030. These magnets, known for their powerful permanent magnetic properties, are increasingly in demand across various industries due to their superior performance and efficiency. The market's expansion is driven by the growing need for advanced technologies and efficient solutions in sectors such as automotive, electronics, and renewable energy. As industries continue to innovate and seek more sustainable and efficient solutions, the demand for high-performance NdFeB magnets is expected to rise. This growth is further supported by advancements in manufacturing processes that enhance the quality and performance of these magnets, making them more accessible and affordable for a broader range of applications. The increasing reliance on these magnets underscores their critical role in modern technology and industry, highlighting their importance in driving innovation and progress across various sectors.

| Report Metric | Details |

| Report Name | High Performance Neodymium Iron Boron Magnets - Market |

| Forecasted market size in 2030 | US$ 7268.7 million |

| CAGR | 3.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hitachi Metals Group, Shin-Etsu, TDK, VAC, Beijing Zhong Ke San Huan Hi-Tech, Yunsheng Company, JL MAG, Zhmag, Earth- Panda |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |