What is High Density Interconnect - Global Market?

High Density Interconnect (HDI) technology represents a significant advancement in the field of electronics, primarily focusing on the miniaturization of electronic components while enhancing their performance. HDI is a type of printed circuit board (PCB) that features a higher wiring density per unit area compared to traditional PCBs. This is achieved through the use of finer lines and spaces, smaller vias, and capture pads, as well as higher connection pad density. The global market for HDI is driven by the increasing demand for compact and efficient electronic devices across various industries. As consumer preferences shift towards smaller, more powerful gadgets, manufacturers are compelled to adopt HDI technology to meet these demands. The versatility of HDI makes it suitable for a wide range of applications, from smartphones and tablets to automotive electronics and medical devices. The market is characterized by rapid technological advancements and a competitive landscape, with key players continuously innovating to offer more efficient and cost-effective solutions. As industries continue to evolve, the demand for HDI technology is expected to grow, driven by its ability to support the development of next-generation electronic devices.

Single Panel, Double Panel, Others in the High Density Interconnect - Global Market:

In the realm of High Density Interconnect (HDI) technology, the classification into single panel, double panel, and other configurations plays a crucial role in determining the application and performance of the final product. Single panel HDI boards are typically used in applications where space is a constraint, and the need for high performance is paramount. These boards are designed with a single layer of circuitry, making them ideal for compact devices such as smartphones and tablets. The simplicity of single panel HDI boards allows for easier manufacturing and lower costs, making them a popular choice for consumer electronics. On the other hand, double panel HDI boards offer a more complex structure with multiple layers of circuitry. This configuration is suitable for applications that require higher performance and more complex functionality, such as automotive electronics and industrial equipment. The additional layers in double panel HDI boards allow for more intricate designs and greater flexibility in terms of component placement and routing. This makes them ideal for applications where reliability and performance are critical. Beyond single and double panel configurations, there are other types of HDI boards that cater to specific needs. These include multi-layer HDI boards, which offer even greater complexity and performance, and flexible HDI boards, which are designed for applications that require flexibility and adaptability. Multi-layer HDI boards are often used in advanced computing and telecommunications equipment, where high-speed data transmission and processing are essential. Flexible HDI boards, on the other hand, are used in applications such as wearable technology and medical devices, where the ability to bend and conform to different shapes is crucial. The choice between single panel, double panel, and other HDI configurations depends on various factors, including the specific requirements of the application, cost considerations, and manufacturing capabilities. As the demand for more compact and efficient electronic devices continues to grow, the market for HDI technology is expected to expand, with manufacturers exploring new configurations and materials to meet the evolving needs of the industry. The versatility and adaptability of HDI technology make it a key enabler of innovation in the electronics sector, driving the development of next-generation devices that are smaller, faster, and more powerful than ever before.

Automotive Electronics, Consumer Electronics, Other Electronic Products in the High Density Interconnect - Global Market:

High Density Interconnect (HDI) technology is increasingly being utilized across various sectors, including automotive electronics, consumer electronics, and other electronic products, due to its ability to enhance performance while reducing size and weight. In the automotive industry, HDI technology is used to develop advanced electronic systems that improve vehicle safety, efficiency, and connectivity. Modern vehicles are equipped with numerous electronic components, such as infotainment systems, advanced driver-assistance systems (ADAS), and engine control units, all of which benefit from the compact and efficient design of HDI boards. The use of HDI technology in automotive electronics allows manufacturers to integrate more features into a smaller space, resulting in lighter and more fuel-efficient vehicles. In the consumer electronics sector, HDI technology is a key enabler of the miniaturization trend, allowing manufacturers to produce smaller, more powerful devices. Smartphones, tablets, and wearable technology are some of the most common applications of HDI technology in this sector. The compact design of HDI boards allows for more components to be integrated into a smaller space, resulting in devices that are not only smaller but also more powerful and feature-rich. This has led to the development of smartphones with advanced features such as high-resolution cameras, faster processors, and longer battery life. Beyond automotive and consumer electronics, HDI technology is also used in a wide range of other electronic products, including medical devices, telecommunications equipment, and industrial machinery. In the medical field, HDI technology is used to develop compact and reliable devices such as pacemakers, hearing aids, and diagnostic equipment. The ability to integrate multiple functions into a small form factor is particularly important in medical applications, where space is often limited, and reliability is critical. In telecommunications, HDI technology is used to develop high-speed networking equipment that supports the growing demand for data transmission and connectivity. The compact design of HDI boards allows for more efficient use of space, resulting in equipment that is not only smaller but also more powerful and capable of handling higher data rates. In industrial applications, HDI technology is used to develop advanced machinery and equipment that require high performance and reliability. The versatility and adaptability of HDI technology make it suitable for a wide range of applications, driving innovation and enabling the development of next-generation electronic products across various industries.

High Density Interconnect - Global Market Outlook:

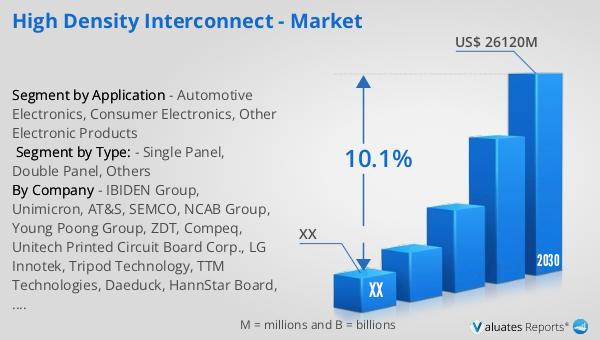

The global market for High Density Interconnect (HDI) was valued at approximately $13.2 billion in 2023, with projections indicating a significant growth trajectory. By 2030, the market is expected to reach an adjusted size of $26.12 billion, reflecting a compound annual growth rate (CAGR) of 10.1% from 2024 to 2030. This growth is driven by the increasing demand for compact and efficient electronic devices across various industries, including automotive, consumer electronics, and telecommunications. The North American market for HDI is also poised for growth, although specific figures for 2023 and 2030 are not provided. The region is expected to experience a steady CAGR during the forecast period, driven by technological advancements and the increasing adoption of HDI technology in various applications. The competitive landscape of the HDI market is characterized by rapid innovation and the continuous development of new materials and manufacturing processes. Key players in the market are focused on expanding their product portfolios and enhancing their production capabilities to meet the growing demand for HDI technology. As industries continue to evolve and the demand for more compact and efficient electronic devices increases, the HDI market is expected to experience sustained growth, driven by its ability to support the development of next-generation electronic products.

| Report Metric | Details |

| Report Name | High Density Interconnect - Market |

| Forecasted market size in 2030 | US$ 26120 million |

| CAGR | 10.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | IBIDEN Group, Unimicron, AT&S, SEMCO, NCAB Group, Young Poong Group, ZDT, Compeq, Unitech Printed Circuit Board Corp., LG Innotek, Tripod Technology, TTM Technologies, Daeduck, HannStar Board, Nan Ya PCB, CMK Corporation, Kingboard, Ellington, CCTC, Wuzhu Technology, Kinwong, Aoshikang, Sierra Circuits, Bittele Electronics, Epec, Würth Elektronik, NOD Electronics, San Francisco Circuits, PCBCart, Advanced Circuits |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |