What is Global Tungsten Steel Cutting Tools Market?

The Global Tungsten Steel Cutting Tools Market is a dynamic and essential segment of the industrial tools industry, characterized by its robust growth and widespread application across various sectors. Tungsten steel, known for its exceptional hardness and resistance to wear, is a critical material in the manufacturing of cutting tools. These tools are indispensable in industries that require precision and durability, such as automotive, aerospace, and electronics. The market for tungsten steel cutting tools is driven by the increasing demand for high-performance tools that can withstand extreme conditions and deliver precise results. As industries continue to evolve and demand more efficient production processes, the need for advanced cutting tools has become more pronounced. This market is also influenced by technological advancements that enhance the capabilities of tungsten steel tools, making them more efficient and cost-effective. With a focus on innovation and quality, manufacturers are continually developing new products to meet the diverse needs of their customers. The global market for tungsten steel cutting tools is poised for significant growth, driven by the expanding industrial sector and the increasing emphasis on precision engineering.

Ordinary Cemented Carbide, Fine-grained Cemented Carbide, Others in the Global Tungsten Steel Cutting Tools Market:

Ordinary Cemented Carbide, Fine-grained Cemented Carbide, and other variants play a crucial role in the Global Tungsten Steel Cutting Tools Market, each offering unique properties and advantages. Ordinary Cemented Carbide is a composite material made from tungsten carbide particles bonded with a metallic binder, typically cobalt. This type of carbide is known for its toughness and resistance to wear, making it suitable for general-purpose cutting applications. It is widely used in industries where durability and cost-effectiveness are paramount. The toughness of ordinary cemented carbide allows it to withstand significant stress and impact, making it ideal for heavy-duty machining tasks. However, its performance may be limited in applications requiring extremely high precision or fine finishes.

Machinery Industry, Automotive Industry, Aerospace Industry, Energy Industry, Electronics Industry, Others in the Global Tungsten Steel Cutting Tools Market:

Fine-grained Cemented Carbide, on the other hand, is characterized by its smaller grain size, which enhances its hardness and wear resistance. This type of carbide is particularly suited for applications that demand high precision and fine surface finishes. The smaller grain size allows for sharper cutting edges, which can improve the quality of the machined surface and extend the tool's lifespan. Fine-grained cemented carbide is often used in industries such as aerospace and electronics, where precision and surface quality are critical. The increased hardness of fine-grained carbide also makes it more resistant to deformation and wear, allowing it to maintain its cutting performance over longer periods. However, the increased hardness can also make it more brittle, which may limit its use in applications involving heavy impact or shock loads.

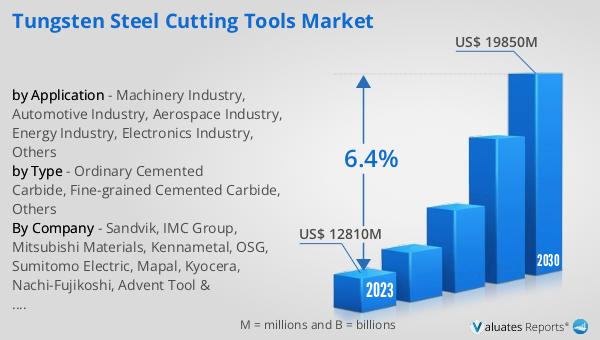

Global Tungsten Steel Cutting Tools Market Outlook:

In addition to ordinary and fine-grained cemented carbides, other variants of tungsten steel cutting tools are available to meet specific industrial needs. These may include ultra-fine-grained carbides, which offer even greater hardness and wear resistance, or specialized coatings that enhance the tool's performance in specific environments. For example, tools with diamond-like carbon coatings can provide superior performance in abrasive or high-temperature applications. The choice of carbide type and any additional coatings or treatments will depend on the specific requirements of the application, including the material being machined, the desired surface finish, and the operating conditions. Manufacturers must carefully consider these factors when selecting the appropriate tungsten steel cutting tools for their needs.

| Report Metric | Details |

| Report Name | Tungsten Steel Cutting Tools Market |

| Accounted market size in 2023 | US$ 12810 million |

| Forecasted market size in 2030 | US$ 19850 million |

| CAGR | 6.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sandvik, IMC Group, Mitsubishi Materials, Kennametal, OSG, Sumitomo Electric, Mapal, Kyocera, Nachi-Fujikoshi, Advent Tool & Manufacturing, Best Carbide Cutting Tools, Garr Tool, Ingersoll Cutting Tool, Ceratizit, Vhf Camfacture, Rock River Tool, SGS Tool, Shanghai Tool, ZCCCT, Tiangong, Harbin No.1 Tool |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |