What is Global Medicine Slicing Machine Market?

The Global Medicine Slicing Machine Market refers to the industry focused on the production and distribution of machines designed to slice medicines into precise portions. These machines are essential in the pharmaceutical sector, where accuracy and efficiency are paramount. They are used to cut tablets, capsules, and other medicinal forms into smaller, manageable sizes, ensuring that dosages are accurate and consistent. This market is driven by the increasing demand for precision in medication administration, as well as the need for efficient recycling processes for unused or expired medicines. The machines vary in their capabilities, with some designed for high-volume industrial use and others for smaller-scale operations. As the pharmaceutical industry continues to grow, the demand for advanced slicing machines is expected to rise, driven by technological advancements and the need for improved patient safety and compliance. The market encompasses a wide range of products, from fully-automatic machines that require minimal human intervention to semi-automatic models that offer a balance between automation and manual control.

Fully-automatic, Semi-automatic in the Global Medicine Slicing Machine Market:

In the Global Medicine Slicing Machine Market, machines are generally categorized into two main types: fully-automatic and semi-automatic. Fully-automatic slicing machines are designed to operate with minimal human intervention, making them ideal for large-scale pharmaceutical manufacturing environments. These machines are equipped with advanced sensors and software that allow them to precisely slice medicines at high speeds, ensuring uniformity and reducing the risk of human error. They are often integrated into larger production lines, where they can seamlessly work alongside other automated systems to streamline the manufacturing process. The primary advantage of fully-automatic machines is their efficiency; they can process large volumes of medicine quickly, which is crucial for meeting the high demands of the pharmaceutical industry. Additionally, these machines often come with features such as self-cleaning mechanisms and automated maintenance alerts, which further enhance their operational efficiency and reduce downtime. On the other hand, semi-automatic slicing machines offer a blend of automation and manual control, making them suitable for smaller operations or specialized applications where flexibility is required. These machines typically require an operator to load the medicine and initiate the slicing process, but they still incorporate automated features to ensure precision and consistency. Semi-automatic machines are often favored by smaller pharmaceutical companies or research facilities that need to process smaller batches of medicine or require the ability to quickly switch between different slicing tasks. The manual component of these machines allows for greater control over the slicing process, which can be beneficial when dealing with delicate or unique medicinal forms that require special handling. Both fully-automatic and semi-automatic machines play crucial roles in the Global Medicine Slicing Machine Market, catering to different needs within the pharmaceutical industry. The choice between the two often depends on factors such as production volume, budget, and specific application requirements. While fully-automatic machines offer unparalleled efficiency and are ideal for high-volume production, semi-automatic machines provide the flexibility and control needed for more specialized tasks. As technology continues to advance, we can expect to see further innovations in both types of machines, with improvements in areas such as speed, precision, and ease of use. These advancements will likely drive further growth in the Global Medicine Slicing Machine Market, as pharmaceutical companies seek to enhance their production capabilities and meet the ever-increasing demand for medicines worldwide.

Tablet Recycling, Capsule Recycling, Sugar-coated Tablet Recycling, Other in the Global Medicine Slicing Machine Market:

The Global Medicine Slicing Machine Market finds its applications in various areas, including tablet recycling, capsule recycling, sugar-coated tablet recycling, and other specialized uses. In tablet recycling, these machines play a vital role in breaking down unused or expired tablets into smaller pieces, which can then be processed for safe disposal or repurposing. This process not only helps in reducing pharmaceutical waste but also ensures that valuable resources are not lost. The precision of slicing machines ensures that tablets are cut accurately, allowing for efficient recycling and minimizing the risk of contamination. Similarly, in capsule recycling, slicing machines are used to open capsules and separate their contents. This is particularly important for capsules that contain valuable or hazardous materials, as it allows for the safe extraction and handling of these substances. The machines are designed to handle capsules of various sizes and compositions, ensuring that the recycling process is both efficient and safe. By facilitating the recycling of capsules, these machines contribute to the sustainability efforts of pharmaceutical companies and help in reducing the environmental impact of pharmaceutical waste. Sugar-coated tablet recycling is another area where medicine slicing machines are extensively used. Sugar-coated tablets present unique challenges due to their hard outer layer, which can be difficult to penetrate. However, advanced slicing machines are equipped with specialized blades and mechanisms that can effectively cut through the coating without damaging the core of the tablet. This precision is crucial for ensuring that the active ingredients within the tablet are preserved during the recycling process. By enabling the recycling of sugar-coated tablets, these machines help in recovering valuable materials and reducing waste. Beyond these specific applications, medicine slicing machines are also used in other areas of the pharmaceutical industry. For instance, they can be employed in research and development settings, where precise slicing is required for testing and analysis purposes. Additionally, they are used in the production of customized medications, where specific dosages or formulations are needed. The versatility of these machines makes them an indispensable tool in the pharmaceutical sector, supporting a wide range of applications and contributing to the overall efficiency and sustainability of the industry.

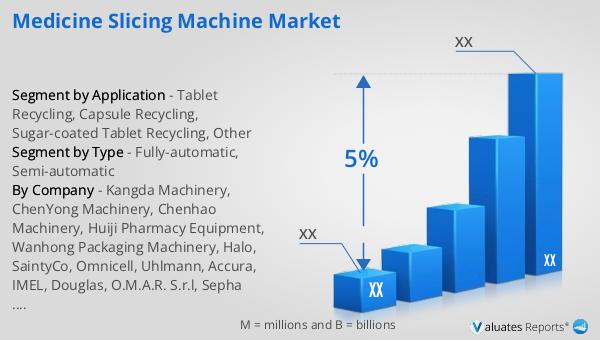

Global Medicine Slicing Machine Market Outlook:

The outlook for the Global Medicine Slicing Machine Market is closely tied to the broader trends in the pharmaceutical industry. In 2022, the global pharmaceutical market was valued at approximately 1,475 billion USD, with an expected compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, rising healthcare needs, and advancements in medical technology. In comparison, the chemical drug market, which forms a significant part of the pharmaceutical industry, was estimated to grow from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This steady growth highlights the ongoing demand for chemical drugs and the need for efficient manufacturing processes, including the use of advanced slicing machines. As the pharmaceutical market continues to expand, the demand for medicine slicing machines is expected to rise in tandem. These machines are essential for ensuring the precision and efficiency of pharmaceutical manufacturing processes, particularly in the production and recycling of tablets and capsules. The growth of the chemical drug market further underscores the importance of these machines, as they play a crucial role in the production of chemical-based medications. By enabling precise slicing and efficient recycling, medicine slicing machines contribute to the overall sustainability and cost-effectiveness of pharmaceutical manufacturing. In conclusion, the Global Medicine Slicing Machine Market is poised for growth alongside the broader pharmaceutical industry. As demand for pharmaceutical products continues to rise, driven by factors such as population growth and technological advancements, the need for efficient and precise slicing machines will become increasingly important. These machines not only support the production of high-quality medications but also contribute to sustainability efforts by facilitating the recycling of pharmaceutical waste. As such, they are an integral part of the pharmaceutical manufacturing process, supporting the industry's growth and evolution in the coming years.

| Report Metric | Details |

| Report Name | Medicine Slicing Machine Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kangda Machinery, ChenYong Machinery, Chenhao Machinery, Huiji Pharmacy Equipment, Wanhong Packaging Machinery, Halo, SaintyCo, Omnicell, Uhlmann, Accura, IMEL, Douglas, O.M.A.R. S.r.l, Sepha Limited, RBP Bauer GmbH, Jornen Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |