What is Global Laser Automation Equipment for Lithium Batteries Market?

The Global Laser Automation Equipment for Lithium Batteries Market refers to the industry focused on the development and deployment of laser-based technologies specifically designed for the production and enhancement of lithium batteries. This market is driven by the increasing demand for lithium batteries, which are essential components in a wide range of applications, from consumer electronics to electric vehicles. Laser automation equipment plays a crucial role in the manufacturing process of lithium batteries by providing precision, efficiency, and speed. These technologies are used in various stages of battery production, including cutting, welding, and marking, ensuring high-quality and reliable battery performance. The market is characterized by continuous innovation and technological advancements, as manufacturers strive to improve battery efficiency and reduce production costs. As the demand for lithium batteries continues to grow, the Global Laser Automation Equipment for Lithium Batteries Market is expected to expand, offering new opportunities for businesses and contributing to the advancement of energy storage solutions worldwide.

Laser Cutting, Laser Welding, Others in the Global Laser Automation Equipment for Lithium Batteries Market:

Laser cutting, laser welding, and other laser-based processes are integral components of the Global Laser Automation Equipment for Lithium Batteries Market. Laser cutting is a precise and efficient method used to shape and size various components of lithium batteries. This process involves using a high-powered laser beam to cut through materials with extreme accuracy, ensuring that each component fits perfectly within the battery assembly. The precision of laser cutting minimizes material waste and enhances the overall quality of the battery components. Laser welding, on the other hand, is a technique used to join different parts of the battery together. This process involves using a laser to melt and fuse materials, creating strong and durable bonds. Laser welding is particularly important in the production of lithium batteries, as it ensures the integrity and reliability of the battery structure. The use of lasers in welding allows for precise control over the welding process, resulting in high-quality joints that can withstand the demands of various applications. In addition to cutting and welding, other laser-based processes are also employed in the production of lithium batteries. These include laser marking, which is used to engrave or etch information onto battery components, and laser cleaning, which is used to remove contaminants from surfaces. Each of these processes plays a vital role in ensuring the quality and performance of lithium batteries. The integration of laser automation equipment in the production of lithium batteries offers numerous benefits, including increased efficiency, reduced production costs, and improved product quality. As the demand for lithium batteries continues to rise, the adoption of laser-based technologies is expected to grow, driving further advancements in the Global Laser Automation Equipment for Lithium Batteries Market.

Power Battery, Energy Storage Battery, Other in the Global Laser Automation Equipment for Lithium Batteries Market:

The usage of Global Laser Automation Equipment for Lithium Batteries Market extends across various applications, including power batteries, energy storage batteries, and other specialized battery types. In the realm of power batteries, which are primarily used in electric vehicles and other high-power applications, laser automation equipment plays a crucial role in enhancing battery performance and reliability. The precision and efficiency of laser-based processes ensure that power batteries are manufactured to the highest standards, capable of delivering the necessary power and energy density required for demanding applications. Laser cutting and welding are particularly important in the production of power batteries, as they ensure the structural integrity and optimal performance of the battery cells. In the field of energy storage batteries, which are used to store energy for later use in applications such as renewable energy systems and grid stabilization, laser automation equipment is essential for producing high-quality and reliable battery systems. The precision and accuracy of laser-based processes ensure that energy storage batteries are manufactured with the necessary specifications to meet the demands of various energy storage applications. Laser technologies also play a role in the production of other specialized battery types, such as those used in consumer electronics and medical devices. The versatility and adaptability of laser automation equipment make it an ideal choice for manufacturing a wide range of battery types, each with its own unique requirements and specifications. As the demand for lithium batteries continues to grow across various industries, the usage of laser automation equipment is expected to expand, driving further advancements in battery technology and production.

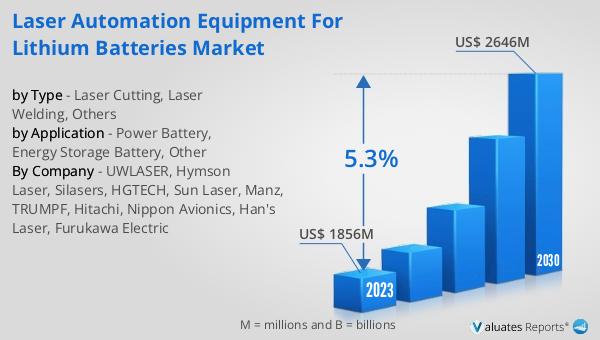

Global Laser Automation Equipment for Lithium Batteries Market Outlook:

The global market for Laser Automation Equipment for Lithium Batteries was valued at approximately $1.856 billion in 2023. This market is projected to grow significantly, reaching an estimated value of $2.646 billion by the year 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.3% over the forecast period from 2024 to 2030. The increasing demand for lithium batteries, driven by the rise in electric vehicles, renewable energy systems, and consumer electronics, is a key factor contributing to the growth of this market. As manufacturers seek to improve the efficiency and performance of lithium batteries, the adoption of laser automation equipment is expected to increase. This equipment offers numerous benefits, including precision, efficiency, and cost-effectiveness, making it an attractive option for battery manufacturers. The continuous advancements in laser technology and the growing focus on sustainable energy solutions are also expected to drive the growth of the Global Laser Automation Equipment for Lithium Batteries Market. As the market expands, it will offer new opportunities for businesses and contribute to the advancement of energy storage solutions worldwide.

| Report Metric | Details |

| Report Name | Laser Automation Equipment for Lithium Batteries Market |

| Accounted market size in 2023 | US$ 1856 million |

| Forecasted market size in 2030 | US$ 2646 million |

| CAGR | 5.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | UWLASER, Hymson Laser, Silasers, HGTECH, Sun Laser, Manz, TRUMPF, Hitachi, Nippon Avionics, Han's Laser, Furukawa Electric |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |