What is Global Industrial Rotary Screw Air Compressors Market?

The Global Industrial Rotary Screw Air Compressors Market refers to the worldwide industry focused on the production, distribution, and utilization of rotary screw air compressors. These machines are essential in various industrial applications due to their efficiency in compressing air for use in powering tools, machinery, and other equipment. Unlike traditional piston compressors, rotary screw air compressors use two helical screws to compress air, which makes them more efficient, quieter, and capable of continuous operation. This market encompasses a wide range of industries, including manufacturing, construction, and energy, where compressed air is a critical component of operations. The market is driven by the increasing demand for energy-efficient solutions, technological advancements, and the need for reliable and continuous air supply in industrial processes. As industries continue to expand and modernize, the demand for rotary screw air compressors is expected to grow, making this market a vital part of the global industrial landscape. The market's growth is also influenced by factors such as environmental regulations, which push for more sustainable and efficient technologies. Overall, the Global Industrial Rotary Screw Air Compressors Market plays a crucial role in supporting industrial activities worldwide.

Single Stage, Double Stage, Multistage in the Global Industrial Rotary Screw Air Compressors Market:

In the Global Industrial Rotary Screw Air Compressors Market, compressors are categorized based on their stages: single-stage, double-stage, and multistage. Each type serves different industrial needs and offers unique advantages. Single-stage rotary screw air compressors are designed to compress air in a single step. They are typically used in applications where moderate pressure is sufficient, such as in small workshops or for powering pneumatic tools. These compressors are known for their simplicity, cost-effectiveness, and ease of maintenance. However, they may not be suitable for applications requiring high pressure or continuous operation over extended periods. Double-stage rotary screw air compressors, on the other hand, compress air in two stages, allowing for higher pressure output and improved efficiency. This makes them ideal for more demanding industrial applications, such as in manufacturing plants or large-scale construction projects. The two-stage process reduces the workload on each stage, resulting in less wear and tear and longer equipment life. Additionally, double-stage compressors are more energy-efficient, which can lead to significant cost savings over time. Multistage rotary screw air compressors take the concept further by incorporating more than two stages of compression. These compressors are used in industries where extremely high pressure is required, such as in chemical processing or oil and gas exploration. The multistage design allows for precise control over pressure levels and enhances the overall efficiency of the compression process. While they are more complex and expensive than single or double-stage compressors, their ability to deliver high pressure and reliability makes them indispensable in certain industrial sectors. The choice between single-stage, double-stage, and multistage compressors depends on various factors, including the specific pressure requirements, the nature of the application, and budget constraints. Industries must carefully assess their needs and select the appropriate type of compressor to ensure optimal performance and cost-effectiveness. As the Global Industrial Rotary Screw Air Compressors Market continues to evolve, advancements in technology are likely to enhance the capabilities and efficiency of these compressors, further expanding their applications across different sectors.

Oil and Gas, Power Generation, Chemical, Food and Beverages, Mining and Metals, Others in the Global Industrial Rotary Screw Air Compressors Market:

The Global Industrial Rotary Screw Air Compressors Market finds extensive usage across various industries, including oil and gas, power generation, chemical, food and beverages, mining and metals, and others. In the oil and gas industry, rotary screw air compressors are crucial for operations such as drilling, extraction, and refining. They provide a reliable source of compressed air for powering equipment and tools, ensuring efficient and continuous operations in harsh environments. The compressors' ability to deliver high pressure and withstand extreme conditions makes them ideal for this sector. In power generation, rotary screw air compressors are used to supply compressed air for cooling, cleaning, and other auxiliary processes. They play a vital role in maintaining the efficiency and reliability of power plants, whether they are coal, gas, or renewable energy-based. The chemical industry relies on rotary screw air compressors for various applications, including the production of chemicals, pharmaceuticals, and petrochemicals. These compressors provide the necessary air pressure for processes such as mixing, conveying, and packaging, ensuring product quality and consistency. In the food and beverages sector, rotary screw air compressors are used for tasks such as bottling, packaging, and pneumatic conveying. They help maintain hygiene and safety standards by providing clean and oil-free compressed air, which is essential for food processing and packaging. The mining and metals industry utilizes rotary screw air compressors for drilling, blasting, and material handling. These compressors provide the power needed for heavy-duty equipment and ensure efficient extraction and processing of minerals and metals. Other industries, such as automotive, textiles, and electronics, also benefit from the versatility and efficiency of rotary screw air compressors. They are used for tasks ranging from assembly line operations to quality control and testing. Overall, the Global Industrial Rotary Screw Air Compressors Market plays a critical role in supporting the diverse needs of various industries, contributing to their productivity and growth.

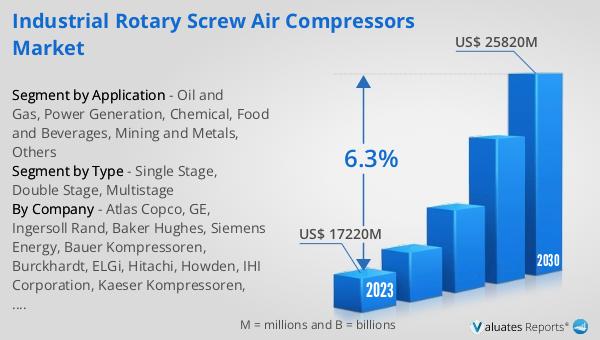

Global Industrial Rotary Screw Air Compressors Market Outlook:

The outlook for the Global Industrial Rotary Screw Air Compressors Market indicates a promising growth trajectory. In 2023, the market was valued at approximately US$ 17,220 million. Looking ahead, it is projected to reach around US$ 25,820 million by the year 2030. This anticipated growth reflects a compound annual growth rate (CAGR) of 6.3% during the forecast period from 2024 to 2030. This upward trend is driven by several factors, including the increasing demand for energy-efficient and reliable air compression solutions across various industries. As businesses strive to enhance operational efficiency and reduce energy consumption, the adoption of advanced rotary screw air compressors is expected to rise. Additionally, technological advancements and innovations in compressor design and functionality are likely to contribute to market expansion. The growing emphasis on sustainability and environmental regulations also plays a significant role in shaping the market's future. Industries are increasingly seeking compressors that offer reduced emissions and lower energy consumption, aligning with global efforts to combat climate change. As a result, manufacturers are focusing on developing eco-friendly and energy-efficient compressor models to meet these demands. Overall, the Global Industrial Rotary Screw Air Compressors Market is poised for substantial growth, driven by the need for efficient and sustainable air compression solutions in various industrial sectors.

| Report Metric | Details |

| Report Name | Industrial Rotary Screw Air Compressors Market |

| Accounted market size in 2023 | US$ 17220 million |

| Forecasted market size in 2030 | US$ 25820 million |

| CAGR | 6.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Atlas Copco, GE, Ingersoll Rand, Baker Hughes, Siemens Energy, Bauer Kompressoren, Burckhardt, ELGi, Hitachi, Howden, IHI Corporation, Kaeser Kompressoren, Kaishan Compressor, Kobelco Compressors, MAN Energy Solutions, MITSUBISHI HEAVY INDUSTRIES, Quincy Compressor, Sullair, Hanwha Power Systems, Gardner Denver |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |