What is Global High-Temperature Coating Market?

The Global High-Temperature Coating Market is a specialized segment within the coatings industry that focuses on products designed to withstand extreme temperatures. These coatings are essential for protecting surfaces and materials that are exposed to high heat, preventing damage and degradation. They are used in various industries, including automotive, aerospace, marine, and industrial applications, where components are often subjected to intense heat. High-temperature coatings are formulated to provide thermal insulation, corrosion resistance, and durability, ensuring the longevity and performance of the coated materials. The market for these coatings is driven by the increasing demand for high-performance materials in industries that operate under harsh conditions. As technology advances and industries continue to push the boundaries of what materials can endure, the need for reliable high-temperature coatings grows. These coatings not only enhance the lifespan of equipment and structures but also contribute to safety and efficiency by maintaining the integrity of materials under extreme conditions. The market is characterized by a range of products, including liquid resins, polymer coatings, and heat-resistant powders, each offering unique properties tailored to specific applications.

Liquid Resin and Polymer Coating, Heat-Resistant Powder Coating, Others in the Global High-Temperature Coating Market:

Liquid Resin and Polymer Coatings are a significant segment within the Global High-Temperature Coating Market. These coatings are formulated using advanced resins and polymers that provide excellent adhesion, flexibility, and resistance to high temperatures. They are particularly valued for their ability to form a protective barrier on surfaces, preventing oxidation and corrosion. This makes them ideal for use in environments where metal surfaces are exposed to high heat and corrosive elements. The versatility of liquid resin and polymer coatings allows them to be applied to a wide range of substrates, including metals, ceramics, and composites. They are commonly used in industries such as automotive, aerospace, and power generation, where components are subjected to extreme thermal conditions. Heat-Resistant Powder Coatings, on the other hand, offer a different set of advantages. These coatings are applied as a dry powder and then cured under heat to form a hard, durable finish. They are known for their excellent thermal stability and resistance to chipping, scratching, and fading. Heat-resistant powder coatings are often used in applications where a tough, long-lasting finish is required, such as in the manufacturing of industrial equipment and machinery. The ability to withstand high temperatures without degrading makes them a popular choice for components that operate in harsh environments. Other types of high-temperature coatings include ceramic coatings, which provide exceptional thermal insulation and are often used in aerospace and automotive applications. These coatings are designed to reflect heat and protect underlying materials from thermal shock and oxidation. The Global High-Temperature Coating Market is diverse, with each type of coating offering unique benefits tailored to specific industrial needs. As industries continue to evolve and demand more from their materials, the development of innovative high-temperature coatings remains a critical area of focus.

Automotive, Fireplaces Application, Aerospace, Marine, Power/Chemical Plants/Refineries, Agriculture and Construction Equipment (ACE), Others in the Global High-Temperature Coating Market:

The usage of Global High-Temperature Coating Market products spans a wide range of industries, each with its unique requirements and challenges. In the automotive sector, high-temperature coatings are used to protect engine components, exhaust systems, and other parts that are exposed to extreme heat. These coatings help improve the efficiency and longevity of vehicles by preventing thermal degradation and corrosion. In fireplaces and heating applications, high-temperature coatings are essential for protecting metal surfaces from the intense heat generated by fires. They ensure that fireplaces and stoves maintain their structural integrity and aesthetic appeal over time. In the aerospace industry, high-temperature coatings play a crucial role in protecting aircraft components from the extreme temperatures encountered during flight. These coatings help maintain the performance and safety of aircraft by preventing thermal damage and corrosion. In the marine industry, high-temperature coatings are used to protect ship components from the harsh conditions of the sea, including high temperatures and corrosive saltwater. These coatings help extend the lifespan of marine vessels and reduce maintenance costs. In power plants, chemical plants, and refineries, high-temperature coatings are used to protect equipment and infrastructure from the extreme heat and corrosive chemicals encountered in these environments. These coatings help ensure the safe and efficient operation of these facilities by preventing equipment failure and reducing downtime. In the agriculture and construction equipment (ACE) sector, high-temperature coatings are used to protect machinery and equipment from the heat generated during operation. These coatings help improve the durability and performance of equipment, reducing maintenance costs and downtime. Other applications of high-temperature coatings include the protection of industrial equipment, pipelines, and infrastructure from the damaging effects of heat and corrosion. The versatility and effectiveness of high-temperature coatings make them an essential component in a wide range of industries, helping to improve the performance, safety, and longevity of materials and equipment.

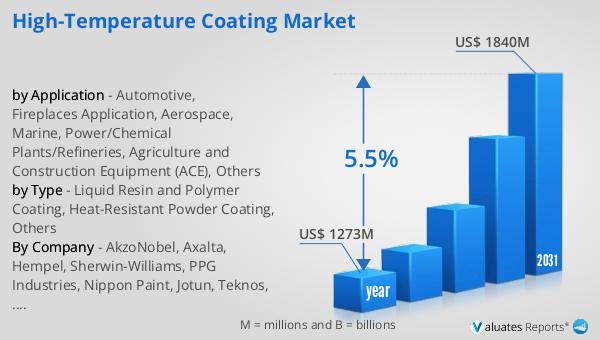

Global High-Temperature Coating Market Outlook:

The outlook for the Global High-Temperature Coating Market is promising, with significant growth anticipated in the coming years. In 2023, the market was valued at approximately US$ 1181 million, and it is expected to reach around US$ 1754 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.5% from 2024 to 2030. This growth is driven by the increasing demand for high-performance coatings in industries that operate under extreme conditions. The market is dominated by a few key players, with the top five companies accounting for about 63% of the market share. Among the various product types, Liquid Resin and Polymer Coating is the largest segment, holding a 33% share of the market. This segment's prominence is due to its versatility and effectiveness in providing thermal protection and corrosion resistance. In terms of applications, the Power/Chemical Plants/Refineries sector is the largest, occupying a 42% share of the market. This is attributed to the critical need for high-temperature coatings in these industries to ensure the safe and efficient operation of equipment and infrastructure. As industries continue to evolve and demand more from their materials, the development of innovative high-temperature coatings remains a critical area of focus.

| Report Metric | Details |

| Report Name | High-Temperature Coating Market |

| Accounted market size in 2023 | US$ 1181 million |

| Forecasted market size in 2030 | US$ 1754 million |

| CAGR | 5.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AkzoNobel, Axalta, Hempel, Sherwin-Williams, PPG Industries, Nippon Paint, Jotun, Teknos, Beijing Zhi Sheng Wei Hua Chemical Co. Ltd., Aremco, Belzona International, Korthals Lakfabriek, Hentzen Coatings, Osaka Paint, Okitsumo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |