What is Global High Barrier PVDC Film Market?

The Global High Barrier PVDC Film Market is a specialized segment within the packaging industry that focuses on films made from polyvinylidene chloride (PVDC). These films are known for their exceptional barrier properties, which make them highly effective in protecting products from moisture, oxygen, and other environmental factors. This makes them particularly valuable in industries where product preservation is critical, such as food packaging, pharmaceuticals, and electronics. The market for these films is driven by the increasing demand for longer shelf life and enhanced product safety. As consumer awareness about food safety and quality grows, so does the need for packaging solutions that can effectively extend the freshness and usability of products. Additionally, the rise in e-commerce and global trade has further fueled the demand for high barrier films, as products need to withstand long shipping times and varying environmental conditions. The Global High Barrier PVDC Film Market is characterized by continuous innovation, with manufacturers constantly developing new formulations and technologies to improve the performance and sustainability of these films. As a result, this market is poised for steady growth as it adapts to the evolving needs of various industries.

Coated Film, Blown Film in the Global High Barrier PVDC Film Market:

Coated films and blown films are two significant types of films within the Global High Barrier PVDC Film Market, each offering unique properties and applications. Coated films are typically created by applying a thin layer of PVDC onto a substrate, which can be made from materials like polyester, polypropylene, or nylon. This coating process enhances the barrier properties of the substrate, making it more resistant to moisture, gases, and aromas. Coated films are widely used in the food packaging industry, where they help maintain the freshness and quality of perishable goods. They are also used in pharmaceutical packaging to protect sensitive medications from environmental factors that could compromise their efficacy. The versatility of coated films allows them to be tailored to specific applications, with varying thicknesses and coating formulations available to meet different requirements. On the other hand, blown films are produced through a process known as film blowing, where molten PVDC is extruded through a circular die to form a continuous tube. This tube is then inflated to the desired size and thickness before being cooled and wound onto rolls. Blown films are known for their excellent mechanical properties, including strength and flexibility, which make them suitable for a wide range of applications. In the food industry, blown films are often used for packaging products that require a high level of protection, such as meats, cheeses, and snacks. Their ability to form tight seals and resist punctures makes them ideal for vacuum packaging and modified atmosphere packaging, which are techniques used to extend the shelf life of food products. In addition to food packaging, blown films are also used in the medical field, where they provide a sterile barrier for medical devices and supplies. The production of blown films allows for precise control over film thickness and composition, enabling manufacturers to create films that meet specific performance criteria. Both coated and blown films play a crucial role in the Global High Barrier PVDC Film Market, offering solutions that cater to the diverse needs of industries that require reliable and effective packaging materials. As technology advances, the capabilities of these films continue to expand, providing even greater protection and functionality for a wide range of products.

Medicine, Electronic, Food, Military Industry, Others in the Global High Barrier PVDC Film Market:

The Global High Barrier PVDC Film Market finds extensive usage across various sectors, including medicine, electronics, food, military, and others, due to its superior protective qualities. In the medical field, PVDC films are used to package pharmaceuticals and medical devices, ensuring that they remain sterile and uncontaminated. The films' excellent barrier properties protect sensitive medications from moisture and oxygen, which can degrade their effectiveness. This is particularly important for drugs that are sensitive to environmental conditions and require a stable environment to maintain their potency. In the electronics industry, PVDC films are used to package components that are sensitive to moisture and static electricity. The films provide a protective barrier that prevents damage during storage and transportation, ensuring that electronic components remain functional and reliable. This is crucial for maintaining the performance and longevity of electronic devices, which are often exposed to varying environmental conditions. In the food industry, PVDC films are widely used to package perishable goods, such as meats, cheeses, and snacks. The films' ability to create a high barrier against oxygen and moisture helps extend the shelf life of these products, maintaining their freshness and quality for longer periods. This is particularly important in the context of global trade and e-commerce, where products may be stored and transported over long distances. In the military sector, PVDC films are used to package and protect sensitive equipment and supplies. The films' durability and resistance to environmental factors make them ideal for use in harsh conditions, where equipment must remain operational and protected from damage. Additionally, PVDC films are used in other industries, such as cosmetics and personal care, where they provide a protective barrier for products that are sensitive to environmental factors. Overall, the Global High Barrier PVDC Film Market plays a vital role in ensuring the safety and quality of products across a wide range of industries, providing reliable and effective packaging solutions that meet the diverse needs of consumers and businesses alike.

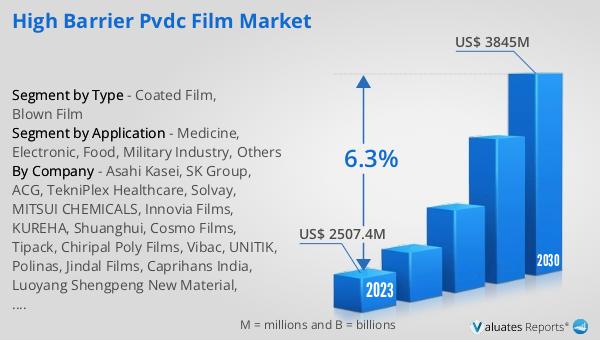

Global High Barrier PVDC Film Market Outlook:

The outlook for the Global High Barrier PVDC Film Market is promising, with significant growth anticipated in the coming years. In 2023, the market was valued at approximately US$ 2507.4 million, reflecting the strong demand for high-performance packaging solutions across various industries. By 2030, the market is expected to reach an estimated value of US$ 3845 million, driven by a compound annual growth rate (CAGR) of 6.3% during the forecast period from 2024 to 2030. This growth is indicative of the increasing recognition of the benefits offered by PVDC films, including their superior barrier properties and versatility in application. As industries continue to prioritize product safety and quality, the demand for high barrier films is likely to rise, further fueling market expansion. The projected growth also underscores the ongoing innovation within the industry, as manufacturers develop new formulations and technologies to enhance the performance and sustainability of PVDC films. This positive market outlook highlights the critical role that high barrier films play in modern packaging solutions, meeting the evolving needs of consumers and businesses worldwide.

| Report Metric | Details |

| Report Name | High Barrier PVDC Film Market |

| Accounted market size in 2023 | US$ 2507.4 million |

| Forecasted market size in 2030 | US$ 3845 million |

| CAGR | 6.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Asahi Kasei, SK Group, ACG, TekniPlex Healthcare, Solvay, MITSUI CHEMICALS, Innovia Films, KUREHA, Shuanghui, Cosmo Films, Tipack, Chiripal Poly Films, Vibac, UNITIK, Polinas, Jindal Films, Caprihans India, Luoyang Shengpeng New Material, Zhejiang Juhua |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |