What is Global Fe-based Superalloy Market?

The Global Fe-based Superalloy Market refers to the worldwide industry focused on the production and application of iron-based superalloys. These materials are engineered to withstand extreme conditions, such as high temperatures and corrosive environments, making them essential in various high-performance applications. Fe-based superalloys are primarily composed of iron, nickel, and chromium, with additional elements like molybdenum, tungsten, and cobalt to enhance their properties. These alloys are known for their exceptional mechanical strength, resistance to thermal creep deformation, and stability at elevated temperatures. The market for these superalloys is driven by their demand in industries such as aerospace, power generation, and general manufacturing, where durability and performance are critical. As technology advances and industries seek materials that can endure more demanding conditions, the Global Fe-based Superalloy Market continues to expand, offering innovative solutions to meet these challenges. The market's growth is also influenced by the increasing need for energy-efficient and environmentally friendly materials, as Fe-based superalloys contribute to reducing emissions and improving fuel efficiency in various applications.

Forging, Casting in the Global Fe-based Superalloy Market:

Forging and casting are two fundamental processes used in the production of components from Fe-based superalloys, each offering distinct advantages and challenges. Forging involves shaping metal using localized compressive forces, typically delivered by a hammer or a die. This process enhances the mechanical properties of Fe-based superalloys by aligning the grain structure, which improves strength and resistance to fatigue. Forged components are often used in applications where high strength and durability are paramount, such as in aerospace engines and power generation turbines. The forging process for Fe-based superalloys requires precise control of temperature and deformation rates to prevent defects and ensure optimal material properties. On the other hand, casting involves pouring molten metal into a mold to achieve the desired shape. This process is advantageous for producing complex geometries and large components that would be difficult or impossible to forge. In the context of Fe-based superalloys, casting allows for the creation of intricate parts with internal cavities, which are essential in many high-performance applications. However, casting can introduce defects such as porosity and segregation, which must be carefully managed through process control and post-casting treatments. The choice between forging and casting in the Global Fe-based Superalloy Market depends on factors such as the required mechanical properties, component size, and complexity. Both processes are integral to the industry, providing the versatility needed to meet diverse application demands. As the market evolves, advancements in forging and casting technologies continue to enhance the performance and reliability of Fe-based superalloy components, driving innovation and growth in this critical sector.

Aerospace, Power Generation, General Industry, Other in the Global Fe-based Superalloy Market:

Fe-based superalloys play a crucial role in various industries, including aerospace, power generation, general industry, and others, due to their exceptional properties. In the aerospace sector, these superalloys are used in the manufacture of jet engines, turbine blades, and other critical components that require high strength and resistance to extreme temperatures. The ability of Fe-based superalloys to maintain their mechanical properties at elevated temperatures makes them ideal for aerospace applications, where performance and safety are paramount. In power generation, Fe-based superalloys are utilized in gas turbines and other equipment that operate under high thermal and mechanical stress. Their resistance to oxidation and corrosion ensures long-term reliability and efficiency, contributing to the overall performance of power plants. In general industry, Fe-based superalloys are employed in the production of tools, dies, and machinery components that demand high wear resistance and durability. These alloys are also used in the chemical and petrochemical industries, where they withstand corrosive environments and high-pressure conditions. Other applications of Fe-based superalloys include medical devices, automotive components, and electronics, where their unique properties offer solutions to complex engineering challenges. The versatility and performance of Fe-based superalloys make them indispensable across a wide range of industries, driving their demand and market growth.

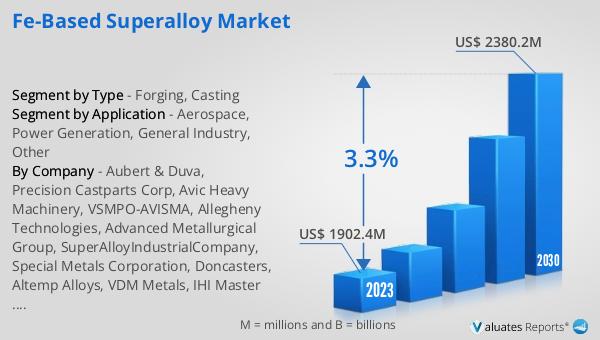

Global Fe-based Superalloy Market Outlook:

The outlook for the Global Fe-based Superalloy Market indicates a steady growth trajectory over the coming years. The market is expected to expand from a valuation of approximately $1,958.9 million in 2024 to around $2,380.2 million by 2030. This growth represents a Compound Annual Growth Rate (CAGR) of 3.3% during the forecast period. The increasing demand for high-performance materials in industries such as aerospace, power generation, and general manufacturing is a key driver of this growth. As these industries continue to evolve and face more stringent performance requirements, the need for materials that can withstand extreme conditions becomes more critical. Fe-based superalloys, with their exceptional mechanical properties and resistance to high temperatures and corrosive environments, are well-positioned to meet these demands. Additionally, the push for energy efficiency and environmental sustainability further supports the market's expansion, as these superalloys contribute to reducing emissions and improving fuel efficiency. The Global Fe-based Superalloy Market's growth reflects the ongoing advancements in material science and engineering, as well as the increasing importance of high-performance materials in modern industrial applications.

| Report Metric | Details |

| Report Name | Fe-based Superalloy Market |

| Accounted market size in 2024 | US$ 1958.9 million |

| Forecasted market size in 2030 | US$ 2380.2 million |

| CAGR | 3.3 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Aubert & Duva, Precision Castparts Corp, Avic Heavy Machinery, VSMPO-AVISMA, Allegheny Technologies, Advanced Metallurgical Group, SuperAlloyIndustrialCompany, Special Metals Corporation, Doncasters, Altemp Alloys, VDM Metals, IHI Master Metal, Supreme Steels, Mikron Tool SA, European Springs & Pressings Ltd, Haynes International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |