What is Global Biopharmaceutical Excipient Manufacturing Market?

The Global Biopharmaceutical Excipient Manufacturing Market is a crucial segment within the pharmaceutical industry, focusing on the production of excipients used in biopharmaceutical formulations. Excipients are inactive substances that serve as the vehicle or medium for a drug or other active substance. They play a vital role in the drug formulation process, ensuring stability, bioavailability, and patient acceptability of the final product. The market for biopharmaceutical excipients is driven by the increasing demand for biologics and biosimilars, which require specialized excipients to maintain their efficacy and safety. These excipients are used in various forms, including tablets, capsules, injectables, and topical formulations. The market is characterized by continuous innovation and development of new excipients to meet the evolving needs of the biopharmaceutical industry. Factors such as regulatory requirements, technological advancements, and the growing focus on personalized medicine are also influencing the market dynamics. The global biopharmaceutical excipient manufacturing market is expected to grow significantly as the demand for advanced drug delivery systems and complex formulations increases. This growth is further supported by the expansion of the pharmaceutical industry and the rising prevalence of chronic diseases worldwide.

Polymers, Solubilizers/Surfactants, Polyols, Proteins/Amino Acids, Others in the Global Biopharmaceutical Excipient Manufacturing Market:

Polymers, solubilizers/surfactants, polyols, proteins/amino acids, and other excipients are essential components in the Global Biopharmaceutical Excipient Manufacturing Market. Polymers are widely used as excipients due to their ability to enhance the stability and bioavailability of biopharmaceutical products. They are used in various forms, such as film coatings, binders, and controlled-release agents. Common polymers used in the industry include cellulose derivatives, polyethylene glycol, and polyvinylpyrrolidone. These polymers help in controlling the release of the active pharmaceutical ingredient (API) and improving the overall performance of the drug. Solubilizers and surfactants are crucial for enhancing the solubility and bioavailability of poorly soluble drugs. They work by reducing the surface tension between the drug and the biological medium, facilitating better absorption and distribution of the drug in the body. Common solubilizers and surfactants include polysorbates, lecithin, and sodium lauryl sulfate. These excipients are particularly important in the formulation of injectable and oral liquid dosage forms. Polyols, such as sorbitol, mannitol, and glycerol, are used as excipients for their sweetening, stabilizing, and moisture-retaining properties. They are commonly used in oral and topical formulations to improve the taste and texture of the product. Polyols also act as humectants, preventing the drying out of formulations and maintaining their stability over time. Proteins and amino acids are used as excipients in biopharmaceutical formulations to stabilize proteins and peptides, which are often sensitive to environmental conditions. They help in maintaining the structural integrity and biological activity of the active ingredient. Common proteins and amino acids used as excipients include albumin, gelatin, and glycine. These excipients are particularly important in the formulation of biologics and biosimilars. Other excipients used in the biopharmaceutical industry include antioxidants, preservatives, and buffering agents. Antioxidants, such as ascorbic acid and tocopherols, are used to prevent the oxidation of the active ingredient, ensuring the stability and efficacy of the product. Preservatives, such as benzyl alcohol and parabens, are used to prevent microbial growth in multi-dose formulations. Buffering agents, such as citric acid and sodium phosphate, are used to maintain the pH of the formulation, ensuring the stability and compatibility of the excipients and the active ingredient. The selection of excipients is a critical step in the drug formulation process, as they can significantly impact the safety, efficacy, and quality of the final product. The development of new excipients and the optimization of existing ones are ongoing processes in the biopharmaceutical industry, driven by the need for more effective and patient-friendly drug delivery systems.

Biotechnology, Pharmaceutical Company, Others in the Global Biopharmaceutical Excipient Manufacturing Market:

The Global Biopharmaceutical Excipient Manufacturing Market plays a significant role in various sectors, including biotechnology, pharmaceutical companies, and other related industries. In the biotechnology sector, excipients are essential for the development and production of biologics, which are complex molecules derived from living organisms. These biologics require specialized excipients to maintain their stability, efficacy, and safety throughout the manufacturing process and during storage. Excipients such as polymers, proteins, and amino acids are commonly used in biotechnology to stabilize proteins and peptides, ensuring their structural integrity and biological activity. The use of excipients in biotechnology is crucial for the successful development of innovative therapies for various diseases, including cancer, autoimmune disorders, and infectious diseases. Pharmaceutical companies rely heavily on excipients for the formulation of a wide range of drug products, including tablets, capsules, injectables, and topical formulations. Excipients are used to enhance the stability, bioavailability, and patient acceptability of the final product. They play a vital role in the drug development process, from pre-formulation studies to the final product manufacturing. Pharmaceutical companies use a variety of excipients, including solubilizers, surfactants, polyols, and buffering agents, to optimize the performance of their drug products. The selection of excipients is a critical step in the formulation process, as they can significantly impact the safety, efficacy, and quality of the final product. In addition to biotechnology and pharmaceutical companies, the Global Biopharmaceutical Excipient Manufacturing Market also serves other industries, such as nutraceuticals and cosmetics. In the nutraceutical industry, excipients are used to enhance the stability and bioavailability of dietary supplements and functional foods. They are used in various forms, such as tablets, capsules, and powders, to improve the taste, texture, and overall quality of the product. In the cosmetics industry, excipients are used to stabilize and enhance the performance of skincare and personal care products. They are used in various forms, such as creams, lotions, and gels, to improve the texture, spreadability, and overall quality of the product. The use of excipients in these industries is driven by the increasing demand for high-quality, effective, and safe products. The Global Biopharmaceutical Excipient Manufacturing Market is expected to grow significantly as the demand for advanced drug delivery systems and complex formulations increases. This growth is further supported by the expansion of the pharmaceutical industry and the rising prevalence of chronic diseases worldwide.

Global Biopharmaceutical Excipient Manufacturing Market Outlook:

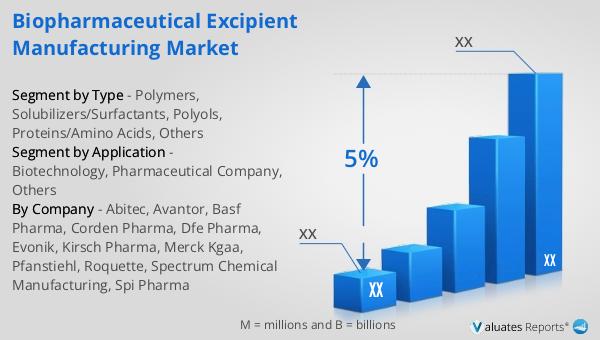

In 2022, the global pharmaceutical market reached a substantial value of 1,475 billion USD, demonstrating a steady growth trajectory with a compound annual growth rate (CAGR) of 5% projected over the next six years. This growth is indicative of the increasing demand for pharmaceutical products and the continuous advancements in drug development and manufacturing processes. In comparison, the chemical drug market has also shown significant growth, with its value rising from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This increase reflects the ongoing demand for chemical drugs, which continue to play a vital role in the treatment of various diseases and medical conditions. The growth in both the pharmaceutical and chemical drug markets highlights the importance of innovation and development in the industry, as companies strive to meet the evolving needs of patients and healthcare providers. The expansion of these markets is driven by factors such as the rising prevalence of chronic diseases, an aging population, and the increasing focus on personalized medicine. As the pharmaceutical industry continues to evolve, the demand for high-quality excipients and advanced drug delivery systems is expected to rise, further supporting the growth of the Global Biopharmaceutical Excipient Manufacturing Market.

| Report Metric | Details |

| Report Name | Biopharmaceutical Excipient Manufacturing Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Abitec, Avantor, Basf Pharma, Corden Pharma, Dfe Pharma, Evonik, Kirsch Pharma, Merck Kgaa, Pfanstiehl, Roquette, Spectrum Chemical Manufacturing, Spi Pharma |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |