What is Forged Rail Wheels - Global Market?

Forged rail wheels are a critical component in the railway industry, providing the necessary strength and durability required for the safe and efficient operation of trains. These wheels are manufactured through a forging process, which involves shaping metal using localized compressive forces. This method enhances the mechanical properties of the wheels, making them more resistant to wear and tear compared to cast wheels. The global market for forged rail wheels is driven by the increasing demand for rail transportation, which is considered a more sustainable and efficient mode of transport compared to road and air travel. As urbanization and industrialization continue to rise, especially in developing countries, the need for reliable rail infrastructure becomes more pronounced. This has led to significant investments in railway projects, further boosting the demand for forged rail wheels. Additionally, the focus on high-speed rail networks in various parts of the world has also contributed to the growth of this market, as these networks require wheels that can withstand higher speeds and loads. The market is characterized by a mix of established players and new entrants, all striving to innovate and improve the quality and performance of forged rail wheels to meet the evolving needs of the railway industry.

Freight Wagons, Passenger Wagons, High Speed Train in the Forged Rail Wheels - Global Market:

Freight wagons, passenger wagons, and high-speed trains are integral components of the railway system, each serving distinct purposes but all relying heavily on forged rail wheels for optimal performance. Freight wagons are designed to transport goods and materials over long distances, and they require wheels that can handle heavy loads and resist wear over time. The durability and strength of forged rail wheels make them ideal for this application, as they can withstand the constant stress and pressure exerted by the weight of the cargo. In passenger wagons, comfort and safety are paramount. Forged rail wheels contribute to a smoother ride by providing stability and reducing vibrations, which is essential for passenger comfort. Moreover, these wheels are crucial for maintaining the safety of the train, as they ensure reliable traction and braking performance. High-speed trains, on the other hand, operate at much higher velocities and require wheels that can endure the increased forces generated at such speeds. Forged rail wheels are particularly suited for high-speed applications due to their enhanced mechanical properties, which include superior tensile strength and resistance to deformation. The global market for forged rail wheels in these segments is influenced by several factors, including technological advancements, regulatory standards, and the expansion of rail networks. As countries invest in upgrading their rail infrastructure to accommodate faster and more efficient trains, the demand for high-quality forged rail wheels is expected to rise. Additionally, the push towards greener transportation solutions has led to increased interest in rail as a sustainable alternative to road and air travel, further driving the market for forged rail wheels. Manufacturers in this market are continuously innovating to develop wheels that not only meet the stringent safety and performance standards but also offer cost-effectiveness and longevity. The competition in the global market is intense, with companies focusing on research and development to gain a competitive edge. They are exploring new materials and manufacturing techniques to enhance the properties of forged rail wheels, ensuring they can meet the demands of modern rail systems. Furthermore, collaborations and partnerships between rail operators and wheel manufacturers are becoming more common, as they work together to develop solutions that address specific challenges faced by the industry. Overall, the global market for forged rail wheels in freight wagons, passenger wagons, and high-speed trains is poised for growth, driven by the increasing need for efficient and reliable rail transportation solutions.

OE Market, After Market in the Forged Rail Wheels - Global Market:

The usage of forged rail wheels in the global market can be broadly categorized into two segments: the Original Equipment (OE) market and the aftermarket. The OE market involves the supply of forged rail wheels to train manufacturers and rail operators for new railway projects and the production of new trains. This segment is driven by the expansion of rail networks and the construction of new rail lines, particularly in emerging economies where urbanization and industrialization are on the rise. As governments and private entities invest in rail infrastructure to improve connectivity and reduce congestion on roads, the demand for high-quality forged rail wheels in the OE market is expected to grow. Manufacturers in this segment focus on producing wheels that meet the specific requirements of new rail projects, including those for high-speed trains and freight wagons. The aftermarket, on the other hand, caters to the replacement and maintenance needs of existing rail systems. As trains and rail infrastructure age, the need for replacement wheels becomes critical to ensure the continued safety and efficiency of rail operations. The aftermarket is driven by the need for regular maintenance and the replacement of worn-out or damaged wheels. This segment is crucial for maintaining the operational integrity of rail systems, as it ensures that trains can continue to run smoothly and safely. The demand in the aftermarket is influenced by factors such as the age of the rail fleet, the frequency of maintenance cycles, and the availability of spare parts. Manufacturers in the aftermarket focus on providing wheels that are compatible with existing rail systems and meet the necessary safety and performance standards. They also offer services such as wheel refurbishment and repair to extend the lifespan of rail wheels and reduce costs for rail operators. The global market for forged rail wheels in both the OE and aftermarket segments is characterized by a high level of competition, with manufacturers striving to offer innovative solutions that meet the evolving needs of the railway industry. Companies are investing in research and development to improve the quality and performance of their products, as well as exploring new materials and manufacturing techniques to enhance the durability and efficiency of forged rail wheels. Additionally, partnerships and collaborations between wheel manufacturers and rail operators are becoming increasingly common, as they work together to develop solutions that address specific challenges faced by the industry. Overall, the usage of forged rail wheels in the OE and aftermarket segments is essential for the continued growth and development of the global railway industry, providing the necessary components for safe, efficient, and reliable rail transportation.

Forged Rail Wheels - Global Market Outlook:

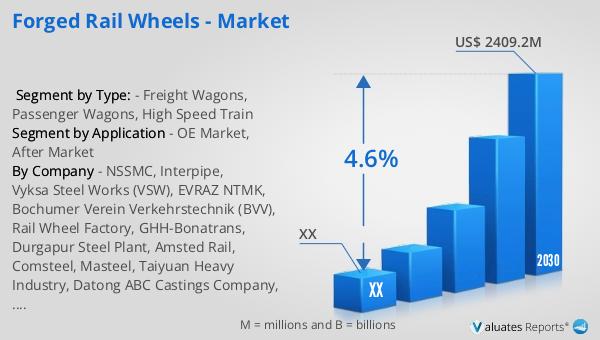

The global market for forged rail wheels was valued at approximately $1,821.3 million in 2023. Looking ahead, it is anticipated that this market will experience growth, reaching an adjusted size of around $2,409.2 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 4.6% over the forecast period from 2024 to 2030. This positive outlook is driven by several factors, including the increasing demand for rail transportation as a sustainable and efficient mode of travel. As urbanization and industrialization continue to expand, particularly in developing regions, the need for robust rail infrastructure becomes more critical. This has led to significant investments in railway projects, further boosting the demand for forged rail wheels. Additionally, the focus on high-speed rail networks in various parts of the world has also contributed to the growth of this market, as these networks require wheels that can withstand higher speeds and loads. The market is characterized by a mix of established players and new entrants, all striving to innovate and improve the quality and performance of forged rail wheels to meet the evolving needs of the railway industry. As the market continues to evolve, manufacturers are expected to focus on research and development to enhance the properties of forged rail wheels, ensuring they can meet the demands of modern rail systems.

| Report Metric | Details |

| Report Name | Forged Rail Wheels - Market |

| Forecasted market size in 2030 | US$ 2409.2 million |

| CAGR | 4.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | NSSMC, Interpipe, Vyksa Steel Works (VSW), EVRAZ NTMK, Bochumer Verein Verkehrstechnik (BVV), Rail Wheel Factory, GHH-Bonatrans, Durgapur Steel Plant, Amsted Rail, Comsteel, Masteel, Taiyuan Heavy Industry, Datong ABC Castings Company, Xinyang Tonghe wheels |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |