What is Food Irradiation Service - Global Market?

Food irradiation is a technology used to improve the safety and extend the shelf life of foods by reducing or eliminating microorganisms and insects. This process involves exposing food to ionizing radiation, such as gamma rays, electron beams, or X-rays. The global market for food irradiation services is growing as more countries recognize the benefits of this technology in ensuring food safety and reducing food waste. By using irradiation, food producers can effectively control pathogens like Salmonella and E. coli, which are responsible for foodborne illnesses. Additionally, irradiation can delay ripening and sprouting in fruits and vegetables, allowing them to stay fresh longer. This technology is particularly beneficial for international trade, as it helps meet the phytosanitary requirements of importing countries. As awareness of food safety and quality increases, the demand for food irradiation services is expected to rise, driving growth in the global market. The market is also supported by advancements in irradiation technology and increased investment in research and development. Overall, food irradiation is a promising solution for enhancing food safety and quality on a global scale.

Electron Beam Radiation, Gamma Radiation, X-Ray Radiation in the Food Irradiation Service - Global Market:

Electron beam radiation, gamma radiation, and X-ray radiation are three primary methods used in food irradiation services, each with unique characteristics and applications. Electron beam radiation, or e-beam, uses high-energy electrons to penetrate food products. This method is highly effective for treating thin products and surfaces, as the electrons have limited penetration depth. E-beam radiation is fast and efficient, making it suitable for high-volume processing. It is commonly used for spices, grains, and certain types of meats. The equipment for e-beam radiation is relatively compact and can be turned on and off, providing flexibility in operations. However, its limited penetration depth can be a drawback for thicker products. Gamma radiation, on the other hand, uses gamma rays emitted from radioactive isotopes like Cobalt-60 or Cesium-137. This method has a deeper penetration capability, making it suitable for bulkier and denser food products. Gamma radiation is widely used for sterilizing spices, herbs, and dried vegetables. It is also effective for treating packaged foods, as the radiation can penetrate through packaging materials. The process is continuous, as the radioactive source emits gamma rays constantly, which can be both an advantage and a limitation. The continuous nature of gamma radiation ensures consistent treatment but requires stringent safety measures and regulatory compliance due to the use of radioactive materials. X-ray radiation combines the benefits of both e-beam and gamma radiation. It uses high-energy X-rays generated by converting electron beams, offering deep penetration similar to gamma rays without the need for radioactive materials. X-ray radiation is versatile and can be used for a wide range of food products, including fruits, vegetables, meats, and seafood. It is particularly advantageous for treating products with varying densities and thicknesses. The technology is safe and environmentally friendly, as it does not involve radioactive isotopes. However, the equipment for X-ray radiation can be more expensive and complex compared to e-beam systems. In the global market for food irradiation services, these three methods are employed based on the specific requirements of the food products being treated. The choice of method depends on factors such as the type of food, desired shelf life, regulatory standards, and cost considerations. As the demand for safe and high-quality food continues to grow, the adoption of these irradiation technologies is expected to increase. Each method offers distinct advantages, allowing food producers to select the most appropriate solution for their needs. The ongoing advancements in irradiation technology and increased awareness of food safety are likely to drive further growth in the global market for food irradiation services.

Fruits and Vegetables, Spices, Grain Foods, Meat and Poultry in the Food Irradiation Service - Global Market:

Food irradiation services play a crucial role in enhancing the safety and quality of various food products, including fruits and vegetables, spices, grain foods, and meat and poultry. In the case of fruits and vegetables, irradiation helps in delaying ripening and preventing spoilage, thereby extending their shelf life. This is particularly beneficial for exporters, as it allows them to transport fresh produce over long distances without compromising quality. Irradiation also helps in controlling pests and pathogens, ensuring that the produce meets the phytosanitary standards of importing countries. For spices, irradiation is an effective method for sterilization, as it eliminates bacteria, molds, and insects without affecting the flavor or aroma. This is important for maintaining the quality and safety of spices, which are often used in small quantities but can have a significant impact on food safety. In the grain foods sector, irradiation is used to control insect infestation and microbial contamination. Grains are susceptible to pests and pathogens during storage and transportation, which can lead to spoilage and loss. By using irradiation, producers can ensure that grains remain safe and free from contaminants, thereby reducing food waste and improving food security. For meat and poultry, irradiation is a valuable tool for reducing the risk of foodborne illnesses. It effectively eliminates pathogens like Salmonella and E. coli, which are common in raw meat products. This enhances the safety of meat and poultry, providing consumers with safer options and reducing the incidence of foodborne diseases. Overall, the use of food irradiation services in these areas contributes to improved food safety, extended shelf life, and reduced food waste. As the global demand for safe and high-quality food continues to rise, the adoption of irradiation technology is expected to increase. This will not only benefit consumers by providing safer food options but also support producers and exporters in meeting international food safety standards. The versatility and effectiveness of irradiation make it a valuable tool in the global food supply chain, ensuring that food products remain safe, fresh, and of high quality from farm to table.

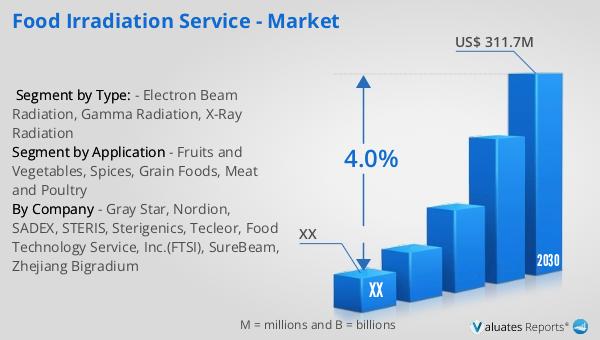

Food Irradiation Service - Global Market Outlook:

In 2023, the global market for food irradiation services was valued at approximately $235.3 million. This market is projected to grow, reaching an estimated size of $311.7 million by 2030, with a compound annual growth rate (CAGR) of 4.0% during the forecast period from 2024 to 2030. This growth reflects the increasing recognition of food irradiation as a vital technology for ensuring food safety and extending shelf life. The North American market, in particular, is a significant contributor to this growth, although specific figures for 2023 and 2030 are not provided. The region's market is expected to expand at a steady CAGR throughout the forecast period, driven by advancements in irradiation technology and a growing emphasis on food safety standards. As more countries adopt food irradiation to meet international trade requirements and consumer demand for safe, high-quality food, the global market is poised for continued expansion. This positive outlook underscores the importance of food irradiation services in the global food industry, highlighting their role in enhancing food safety, reducing waste, and supporting sustainable food production and distribution.

| Report Metric | Details |

| Report Name | Food Irradiation Service - Market |

| Forecasted market size in 2030 | US$ 311.7 million |

| CAGR | 4.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Gray Star, Nordion, SADEX, STERIS, Sterigenics, Tecleor, Food Technology Service, Inc.(FTSI), SureBeam, Zhejiang Bigradium |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |