What is Conformal Coating Inspection System - Global Market?

Conformal coating inspection systems are specialized tools used in the electronics manufacturing industry to ensure that protective coatings applied to electronic components are correctly and uniformly applied. These coatings are essential as they protect sensitive electronic parts from environmental factors such as moisture, dust, chemicals, and temperature extremes, which can lead to corrosion or failure. The global market for these systems is driven by the increasing demand for reliable and durable electronic devices across various industries. As technology advances, the complexity and miniaturization of electronic components increase, necessitating more precise and efficient inspection systems. These systems utilize various technologies, including optical, X-ray, and automated optical inspection (AOI), to detect defects or inconsistencies in the coating. The market is characterized by continuous innovation, with manufacturers striving to develop systems that offer higher accuracy, speed, and ease of use. The growing emphasis on quality control and regulatory compliance in electronics manufacturing further fuels the demand for conformal coating inspection systems. As industries such as automotive, aerospace, and consumer electronics continue to expand, the need for advanced inspection solutions is expected to rise, making this market a critical component of the global electronics manufacturing landscape.

Semi Automatic, Automated, Combined in the Conformal Coating Inspection System - Global Market:

Conformal coating inspection systems can be categorized into semi-automatic, automated, and combined systems, each offering distinct advantages and catering to different needs within the global market. Semi-automatic systems are typically used in smaller production environments where flexibility and cost-effectiveness are crucial. These systems require some level of human intervention, allowing operators to manually adjust settings or inspect specific areas of a component. This flexibility is beneficial for manufacturers who deal with a variety of products or smaller production runs. However, the reliance on human input can lead to inconsistencies and slower inspection times compared to fully automated systems. Automated systems, on the other hand, are designed for high-volume production environments where speed and precision are paramount. These systems utilize advanced technologies such as machine vision and robotics to perform inspections with minimal human intervention. Automated systems can quickly and accurately detect defects, ensuring consistent quality across large batches of products. The efficiency and reliability of these systems make them ideal for industries where high throughput and stringent quality standards are required, such as automotive and consumer electronics. Combined systems offer a hybrid approach, integrating elements of both semi-automatic and automated systems. These systems provide the flexibility to switch between manual and automated modes, allowing manufacturers to adapt to varying production demands. Combined systems are particularly useful in environments where product types and volumes fluctuate, offering a balance between cost, flexibility, and efficiency. The choice between these systems depends on several factors, including production volume, product complexity, and budget constraints. As the global market for conformal coating inspection systems continues to grow, manufacturers are increasingly looking for solutions that offer the best combination of speed, accuracy, and adaptability. Technological advancements are driving the development of more sophisticated systems that can handle the complexities of modern electronics manufacturing. Features such as real-time data analysis, machine learning algorithms, and enhanced imaging capabilities are becoming standard in newer models, further enhancing their appeal. The integration of these advanced features not only improves inspection accuracy but also provides valuable insights into the manufacturing process, enabling manufacturers to optimize production and reduce waste. As industries continue to demand higher quality and reliability from their electronic components, the role of conformal coating inspection systems in ensuring product integrity and compliance will become increasingly important. The global market for these systems is poised for significant growth, driven by the need for advanced inspection solutions that can keep pace with the evolving demands of the electronics industry.

Automotive Electronics, Aerospace, Industrial, Other Application in the Conformal Coating Inspection System - Global Market:

Conformal coating inspection systems play a crucial role in various industries, including automotive electronics, aerospace, industrial applications, and others, by ensuring the reliability and longevity of electronic components. In the automotive electronics sector, these systems are essential for maintaining the performance and safety of electronic systems used in vehicles. As modern vehicles become more reliant on electronic components for functions such as navigation, entertainment, and safety systems, the need for reliable and durable electronics becomes paramount. Conformal coating inspection systems help manufacturers ensure that coatings are applied correctly, protecting components from harsh environmental conditions such as temperature fluctuations, moisture, and vibration. In the aerospace industry, the stakes are even higher, as electronic components must withstand extreme conditions and perform flawlessly. Conformal coating inspection systems are used to verify the integrity of coatings on critical components, ensuring that they can endure the rigors of aerospace environments. The precision and reliability offered by these systems are vital for maintaining the safety and performance of aerospace electronics. In industrial applications, conformal coating inspection systems are used to protect electronic components used in machinery and equipment. These systems help prevent failures caused by exposure to dust, chemicals, and other harsh conditions commonly found in industrial settings. By ensuring the proper application of protective coatings, these systems help extend the lifespan of electronic components and reduce maintenance costs. Other applications of conformal coating inspection systems include consumer electronics, telecommunications, and medical devices. In each of these areas, the need for reliable and durable electronic components is critical, and conformal coating inspection systems play a key role in ensuring product quality and performance. As the demand for advanced electronic devices continues to grow, the importance of conformal coating inspection systems in maintaining the integrity and reliability of these products will only increase. The global market for these systems is expected to expand as industries continue to prioritize quality and reliability in their electronic components.

Conformal Coating Inspection System - Global Market Outlook:

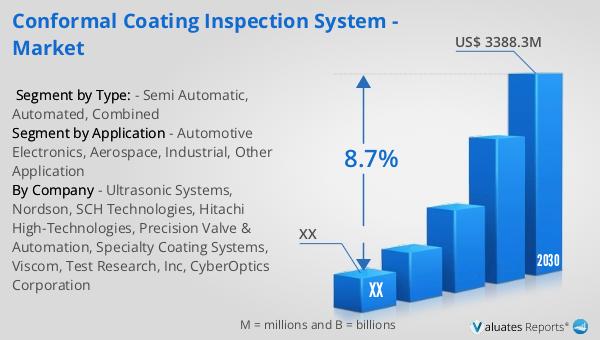

The global market for conformal coating inspection systems was valued at approximately $1,893 million in 2023. This market is projected to grow significantly, reaching an estimated value of $3,388.3 million by 2030. This growth represents a compound annual growth rate (CAGR) of 8.7% during the forecast period from 2024 to 2030. This impressive growth rate underscores the increasing demand for advanced inspection solutions in the electronics manufacturing industry. As industries such as automotive, aerospace, and consumer electronics continue to expand, the need for reliable and efficient inspection systems becomes more critical. The growing complexity and miniaturization of electronic components further drive the demand for sophisticated inspection technologies that can ensure the quality and reliability of these components. Manufacturers are increasingly investing in conformal coating inspection systems to enhance their quality control processes and meet the stringent requirements of their respective industries. The integration of advanced technologies such as machine vision, robotics, and real-time data analysis is expected to further fuel the growth of this market. As the global market for conformal coating inspection systems continues to evolve, manufacturers are likely to focus on developing solutions that offer higher accuracy, speed, and adaptability to meet the diverse needs of their customers. The projected growth of this market highlights the critical role that conformal coating inspection systems play in ensuring the quality and reliability of electronic components across various industries.

| Report Metric | Details |

| Report Name | Conformal Coating Inspection System - Market |

| Forecasted market size in 2030 | US$ 3388.3 million |

| CAGR | 8.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Ultrasonic Systems, Nordson, SCH Technologies, Hitachi High-Technologies, Precision Valve & Automation, Specialty Coating Systems, Viscom, Test Research, Inc, CyberOptics Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |