What is Conductive Textile - Global Market?

Conductive textiles are a fascinating innovation in the textile industry, combining traditional fabric materials with conductive elements to create textiles that can conduct electricity. These textiles are embedded with conductive fibers or coatings, allowing them to transmit electrical signals. This unique property opens up a wide range of applications, from wearable technology to medical devices and beyond. The global market for conductive textiles is expanding rapidly due to the increasing demand for smart textiles in various sectors, including healthcare, sports, and military. These textiles offer the advantage of flexibility and comfort, making them ideal for wearable applications. Additionally, they can be used in the development of sensors, antennas, and other electronic components integrated into clothing. As technology continues to advance, the potential uses for conductive textiles are expected to grow, driving further innovation and market growth. The integration of electronics into textiles represents a significant step forward in the development of smart clothing and other wearable technologies, offering new possibilities for monitoring health, enhancing communication, and improving overall quality of life. The global market for conductive textiles is poised for significant growth as industries continue to explore and adopt these innovative materials.

Cotton, Polyester, Nylon, Wool, Others in the Conductive Textile - Global Market:

Conductive textiles are made from various materials, each offering unique properties and benefits. Cotton, for instance, is a natural fiber known for its softness, breathability, and comfort. When used in conductive textiles, cotton provides a comfortable base that can be worn close to the skin, making it ideal for wearable applications. The natural properties of cotton, such as its ability to absorb moisture, enhance the comfort of conductive textiles, especially in applications where prolonged wear is necessary. Polyester, on the other hand, is a synthetic fiber known for its durability, strength, and resistance to environmental factors such as moisture and UV rays. Conductive textiles made from polyester are often used in applications where durability and longevity are critical, such as in military or industrial settings. Polyester's resistance to stretching and shrinking also makes it a reliable choice for conductive textiles that require consistent performance over time. Nylon, another synthetic fiber, is valued for its elasticity and strength. Conductive textiles made from nylon are often used in applications where flexibility and resilience are important, such as in sportswear or medical devices. Nylon's ability to return to its original shape after stretching makes it an excellent choice for applications that require a snug fit or frequent movement. Wool, a natural fiber known for its warmth and insulation properties, is used in conductive textiles for applications where temperature regulation is important. Wool's natural ability to retain heat while allowing moisture to escape makes it an ideal choice for conductive textiles used in cold environments or for applications that require thermal management. Other materials used in conductive textiles include blends of natural and synthetic fibers, which combine the benefits of both types of materials. These blends can offer a balance of comfort, durability, and performance, making them suitable for a wide range of applications. The choice of material for conductive textiles depends on the specific requirements of the application, including factors such as comfort, durability, flexibility, and environmental resistance. As the market for conductive textiles continues to grow, manufacturers are exploring new materials and combinations to enhance the performance and versatility of these innovative textiles.

Knitted Conductive Textile, Woven Conductive Textile, Non-woven Conductive Textile in the Conductive Textile - Global Market:

Conductive textiles are utilized in various forms, including knitted, woven, and non-woven textiles, each offering distinct advantages for different applications. Knitted conductive textiles are created by interlocking loops of yarn, resulting in a fabric that is highly flexible and stretchable. This flexibility makes knitted conductive textiles ideal for applications that require a close fit and freedom of movement, such as in wearable technology and sportswear. The stretchability of knitted textiles allows them to conform to the body's shape, providing comfort and ease of movement. Additionally, the open structure of knitted textiles allows for excellent breathability, making them suitable for applications where moisture management is important. Woven conductive textiles, on the other hand, are made by interlacing two sets of yarns at right angles, creating a fabric that is strong and durable. The tight structure of woven textiles provides stability and resistance to wear and tear, making them suitable for applications that require durability and strength, such as in military or industrial settings. Woven conductive textiles can also be engineered to provide specific properties, such as water resistance or flame retardancy, enhancing their suitability for specialized applications. Non-woven conductive textiles are made by bonding or felting fibers together, resulting in a fabric that is lightweight and versatile. The lack of a structured weave allows non-woven textiles to be easily shaped and molded, making them ideal for applications that require complex shapes or structures, such as in medical devices or automotive components. Non-woven conductive textiles can also be engineered to provide specific properties, such as filtration or insulation, making them suitable for a wide range of applications. The choice of textile form for conductive textiles depends on the specific requirements of the application, including factors such as flexibility, durability, and performance. As the market for conductive textiles continues to grow, manufacturers are exploring new textile forms and technologies to enhance the performance and versatility of these innovative materials.

Conductive Textile - Global Market Outlook:

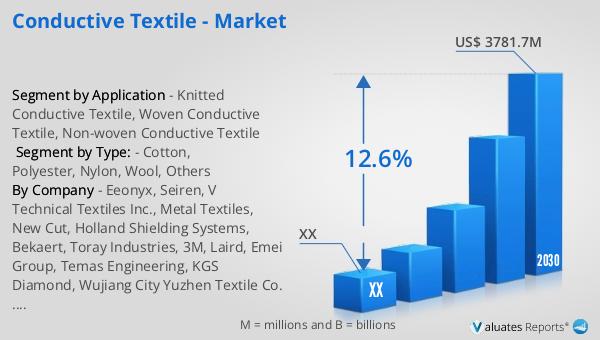

The global market for conductive textiles was valued at approximately $1,624.6 million in 2023, and it is projected to grow significantly, reaching an estimated $3,781.7 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 12.6% during the forecast period from 2024 to 2030. This impressive growth rate reflects the increasing demand for conductive textiles across various industries, driven by the rising adoption of smart textiles and wearable technology. In North America, the market for conductive textiles is also experiencing growth, although specific figures for 2023 and 2030 are not provided. The region is expected to see a steady increase in demand for conductive textiles, driven by advancements in technology and the growing popularity of wearable devices. The North American market is anticipated to benefit from the presence of key industry players and a strong focus on research and development in the field of smart textiles. As industries continue to explore the potential of conductive textiles, the market is poised for significant expansion, offering new opportunities for innovation and growth. The increasing integration of electronics into textiles is expected to drive further advancements in the development of smart clothing and other wearable technologies, enhancing the overall market outlook for conductive textiles.

| Report Metric | Details |

| Report Name | Conductive Textile - Market |

| Forecasted market size in 2030 | US$ 3781.7 million |

| CAGR | 12.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Eeonyx, Seiren, V Technical Textiles Inc., Metal Textiles, New Cut, Holland Shielding Systems, Bekaert, Toray Industries, 3M, Laird, Emei Group, Temas Engineering, KGS Diamond, Wujiang City Yuzhen Textile Co. Ltd, Swift Textile Metalizing, Parker Chomerics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |