What is Butene Copolymer Linear Low Density Polyethylene (C4-LLDPE) - Global Market?

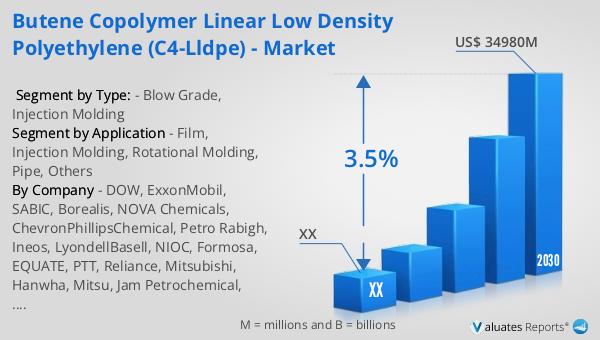

Butene Copolymer Linear Low Density Polyethylene (C4-LLDPE) is a specialized type of polyethylene that has gained significant traction in the global market due to its unique properties and versatile applications. This material is a variant of Linear Low Density Polyethylene (LLDPE) and is characterized by the inclusion of butene as a comonomer, which enhances its flexibility and strength. C4-LLDPE is widely used in various industries due to its excellent tensile strength, impact resistance, and clarity. These properties make it an ideal choice for applications that require durability and transparency. The global market for C4-LLDPE was valued at approximately US$ 27,510 million in 2023 and is projected to grow to US$ 34,980 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.5% from 2024 to 2030. This growth is driven by increasing demand in sectors such as packaging, automotive, and construction, where the material's properties are highly valued. As industries continue to seek materials that offer both performance and cost-effectiveness, C4-LLDPE is poised to maintain its relevance and expand its market presence.

Blow Grade, Injection Molding in the Butene Copolymer Linear Low Density Polyethylene (C4-LLDPE) - Global Market:

Blow molding and injection molding are two prominent applications of Butene Copolymer Linear Low Density Polyethylene (C4-LLDPE) in the global market, each leveraging the material's unique properties to meet specific industrial needs. Blow molding is a manufacturing process used to create hollow plastic parts, such as bottles and containers. C4-LLDPE is particularly suited for blow molding due to its excellent melt strength and flexibility, which allow for the production of lightweight yet durable products. The material's clarity and gloss also enhance the aesthetic appeal of the final products, making them attractive for consumer packaging. In the global market, the demand for blow-molded products is driven by the packaging industry's need for cost-effective and sustainable solutions. C4-LLDPE's recyclability further adds to its appeal, aligning with the growing emphasis on environmental responsibility. Injection molding, on the other hand, is a process used to produce complex and intricate plastic parts by injecting molten material into a mold. C4-LLDPE's low density and high impact resistance make it an ideal choice for injection molding applications. The material's ability to withstand stress and deformation ensures the production of high-quality parts that can endure rigorous use. In the automotive industry, for instance, C4-LLDPE is used to manufacture components that require both strength and flexibility, such as bumpers and interior panels. The electronics industry also benefits from C4-LLDPE's properties, using it to produce durable casings and housings for devices. The global market for injection-molded products is expanding as industries seek materials that offer both performance and cost-efficiency. C4-LLDPE's versatility and adaptability make it a preferred choice for manufacturers looking to optimize production processes and reduce material costs. The global market for C4-LLDPE in blow molding and injection molding is characterized by continuous innovation and development. Manufacturers are investing in research and development to enhance the material's properties and expand its application range. Advances in polymer technology are leading to the creation of C4-LLDPE grades with improved performance characteristics, such as higher temperature resistance and enhanced barrier properties. These developments are opening new opportunities for C4-LLDPE in sectors such as healthcare and food packaging, where stringent regulatory requirements necessitate high-performance materials. As the global market evolves, C4-LLDPE is expected to play a pivotal role in driving innovation and sustainability across various industries. Its unique combination of properties and cost-effectiveness positions it as a material of choice for manufacturers seeking to meet the demands of a dynamic and competitive market.

Film, Injection Molding, Rotational Molding, Pipe, Others in the Butene Copolymer Linear Low Density Polyethylene (C4-LLDPE) - Global Market:

Butene Copolymer Linear Low Density Polyethylene (C4-LLDPE) finds extensive usage across various applications, including film, injection molding, rotational molding, pipe, and others, each benefiting from the material's distinct properties. In the film industry, C4-LLDPE is widely used to produce flexible packaging films, agricultural films, and stretch films. Its excellent tensile strength and puncture resistance make it ideal for packaging applications that require durability and protection. The material's clarity and gloss enhance the visual appeal of packaging films, making them suitable for consumer goods. In agriculture, C4-LLDPE films are used for mulching and greenhouse covers, providing protection against environmental factors while promoting plant growth. In injection molding, C4-LLDPE is used to manufacture a wide range of products, from automotive components to consumer goods. Its low density and high impact resistance make it suitable for producing lightweight yet robust parts. The material's ability to withstand stress and deformation ensures the production of high-quality components that can endure rigorous use. In the automotive industry, C4-LLDPE is used to produce parts such as bumpers and interior panels, where strength and flexibility are essential. The electronics industry also utilizes C4-LLDPE for producing durable casings and housings for devices, benefiting from the material's excellent mechanical properties. Rotational molding is another application where C4-LLDPE is extensively used. This process involves creating large, hollow plastic parts by rotating a mold filled with powdered resin. C4-LLDPE's excellent flow properties and thermal stability make it ideal for rotational molding, allowing for the production of complex shapes with uniform wall thickness. The material's impact resistance and durability make it suitable for manufacturing products such as tanks, containers, and playground equipment. In the pipe industry, C4-LLDPE is used to produce flexible and durable pipes for various applications, including irrigation, drainage, and gas distribution. Its resistance to environmental stress cracking and chemical corrosion ensures long-lasting performance in demanding conditions. Beyond these applications, C4-LLDPE is also used in other areas such as wire and cable insulation, where its electrical insulating properties are highly valued. The material's versatility and adaptability make it a preferred choice for manufacturers seeking to optimize production processes and reduce material costs. As industries continue to seek materials that offer both performance and cost-effectiveness, C4-LLDPE is poised to maintain its relevance and expand its market presence. Its unique combination of properties and cost-effectiveness positions it as a material of choice for manufacturers looking to meet the demands of a dynamic and competitive market.

Butene Copolymer Linear Low Density Polyethylene (C4-LLDPE) - Global Market Outlook:

The global outlook for Butene Copolymer Linear Low Density Polyethylene (C4-LLDPE) indicates a promising growth trajectory. In 2023, the market was valued at approximately US$ 27,510 million, and it is anticipated to reach a revised size of US$ 34,980 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.5% during the forecast period from 2024 to 2030. C4-LLDPE is a variant of Linear Low Density Polyethylene (LLDPE) that incorporates butene as a comonomer, enhancing its flexibility and strength. The material's unique properties, such as excellent tensile strength, impact resistance, and clarity, make it highly sought after in various industries, including packaging, automotive, and construction. As these industries continue to evolve and demand materials that offer both performance and cost-effectiveness, C4-LLDPE is well-positioned to meet these needs. Its recyclability and alignment with environmental sustainability goals further contribute to its growing popularity. The market's expansion is driven by the increasing demand for durable and lightweight materials that can withstand rigorous use while maintaining aesthetic appeal. As a result, C4-LLDPE is expected to play a significant role in shaping the future of material innovation and sustainability across diverse sectors.

| Report Metric | Details |

| Report Name | Butene Copolymer Linear Low Density Polyethylene (C4-LLDPE) - Market |

| Forecasted market size in 2030 | US$ 34980 million |

| CAGR | 3.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | DOW, ExxonMobil, SABIC, Borealis, NOVA Chemicals, ChevronPhillipsChemical, Petro Rabigh, Ineos, LyondellBasell, NIOC, Formosa, EQUATE, PTT, Reliance, Mitsubishi, Hanwha, Mitsu, Jam Petrochemical, Sinopec, CNPC, Secco |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |