What is Automatic Horizontal Folding Cartoning Machine - Global Market?

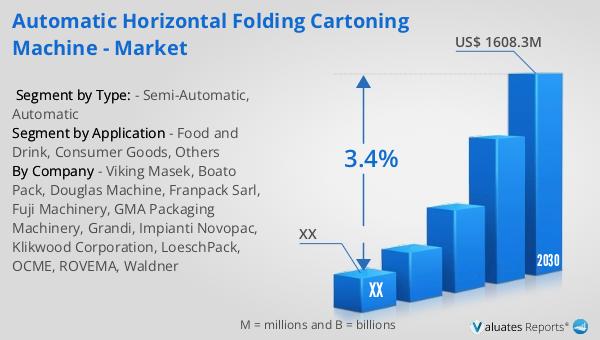

The Automatic Horizontal Folding Cartoning Machine is a sophisticated piece of equipment designed to streamline the packaging process by automatically forming, folding, and sealing cartons. This machine is widely used in various industries due to its efficiency and ability to handle high volumes of products with precision. The global market for these machines is expanding as businesses seek to improve their packaging operations and reduce labor costs. In 2023, the market was valued at approximately US$ 1276 million, and it is projected to grow to US$ 1608.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.4% from 2024 to 2030. This growth is driven by the increasing demand for automation in packaging processes, as well as the need for consistent and reliable packaging solutions. The automatic horizontal folding cartoning machine is particularly valued for its ability to produce uniform cartons quickly, which is essential for maintaining product quality and meeting consumer expectations. As industries continue to evolve and prioritize efficiency, the demand for such automated solutions is expected to rise, making these machines a crucial component in modern manufacturing and packaging operations.

Semi-Automatic, Automatic in the Automatic Horizontal Folding Cartoning Machine - Global Market:

When discussing the global market for Automatic Horizontal Folding Cartoning Machines, it's essential to differentiate between semi-automatic and fully automatic machines, as each serves distinct needs and offers unique advantages. Semi-automatic machines require some level of human intervention, typically for loading products or initiating the packaging process. These machines are often favored by smaller businesses or those with lower production volumes, as they offer a balance between automation and manual control. They are generally more affordable than fully automatic machines, making them an attractive option for companies looking to improve efficiency without a significant upfront investment. Semi-automatic machines are also versatile, allowing operators to handle a variety of product sizes and shapes with relative ease. On the other hand, fully automatic horizontal folding cartoning machines are designed to operate with minimal human intervention, making them ideal for large-scale production environments. These machines can handle high volumes of products with speed and precision, significantly reducing the need for manual labor and the potential for human error. Fully automatic machines are equipped with advanced features such as sensors and programmable logic controllers (PLCs), which enable them to adapt to different packaging requirements and ensure consistent quality. While the initial investment for fully automatic machines is higher, the long-term benefits in terms of efficiency, productivity, and cost savings often justify the expense. In the global market, the demand for both semi-automatic and fully automatic machines is influenced by factors such as industry type, production volume, and budget constraints. Companies in sectors like food and beverage, pharmaceuticals, and consumer goods are increasingly adopting fully automatic machines to meet the growing demand for packaged products and to comply with stringent quality standards. Meanwhile, businesses in niche markets or those with fluctuating production needs may opt for semi-automatic machines to maintain flexibility and control over their packaging processes. As technology continues to advance, the line between semi-automatic and fully automatic machines is becoming increasingly blurred, with many manufacturers offering hybrid solutions that combine the best features of both. This trend is expected to continue as companies seek to optimize their packaging operations and remain competitive in an ever-evolving market landscape.

Food and Drink, Consumer Goods, Others in the Automatic Horizontal Folding Cartoning Machine - Global Market:

The usage of Automatic Horizontal Folding Cartoning Machines spans across various industries, with significant applications in the food and drink, consumer goods, and other sectors. In the food and drink industry, these machines are indispensable for packaging a wide range of products, from cereals and snacks to beverages and frozen foods. The ability to quickly and efficiently package products ensures that they remain fresh and protected during transportation and storage. Automatic cartoning machines help maintain hygiene standards by minimizing human contact with the products, which is crucial in the food industry. Additionally, these machines can handle different packaging materials and sizes, allowing manufacturers to cater to diverse consumer preferences and market demands. In the consumer goods sector, automatic horizontal folding cartoning machines are used to package items such as cosmetics, personal care products, and household goods. The precision and consistency offered by these machines ensure that products are securely packaged, reducing the risk of damage during transit. This is particularly important for fragile or high-value items, where packaging integrity is paramount. The flexibility of these machines allows manufacturers to create customized packaging solutions that enhance brand visibility and appeal to consumers. Beyond food and consumer goods, automatic horizontal folding cartoning machines find applications in other industries, including pharmaceuticals, electronics, and automotive. In the pharmaceutical industry, these machines are used to package medicines and healthcare products, ensuring that they are protected from contamination and tampering. The ability to produce tamper-evident packaging is a critical feature for pharmaceutical companies, as it helps maintain product integrity and comply with regulatory requirements. In the electronics industry, these machines are used to package components and devices, providing protection against static, moisture, and physical damage. The automotive industry also benefits from the use of automatic cartoning machines, as they are used to package spare parts and accessories, ensuring that they reach customers in optimal condition. Overall, the versatility and efficiency of automatic horizontal folding cartoning machines make them an essential tool for businesses across various sectors, helping them meet the demands of modern consumers and maintain a competitive edge in the global market.

Automatic Horizontal Folding Cartoning Machine - Global Market Outlook:

The global market for Automatic Horizontal Folding Cartoning Machines was valued at approximately US$ 1276 million in 2023. It is anticipated to grow to a revised size of US$ 1608.3 million by 2030, with a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2024 to 2030. These machines are automated equipment designed for the efficient production of cartons, which are essential for packaging a wide range of products across various industries. The growth in this market is driven by the increasing demand for automation in packaging processes, as businesses seek to enhance efficiency, reduce labor costs, and maintain consistent product quality. Automatic horizontal folding cartoning machines are particularly valued for their ability to produce uniform cartons quickly and accurately, which is crucial for maintaining product integrity and meeting consumer expectations. As industries continue to evolve and prioritize efficiency, the demand for such automated solutions is expected to rise, making these machines a vital component in modern manufacturing and packaging operations. The market's expansion reflects the growing recognition of the benefits of automation in packaging, as well as the need for reliable and efficient packaging solutions in an increasingly competitive global market.

| Report Metric | Details |

| Report Name | Automatic Horizontal Folding Cartoning Machine - Market |

| Forecasted market size in 2030 | US$ 1608.3 million |

| CAGR | 3.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Viking Masek, Boato Pack, Douglas Machine, Franpack Sarl, Fuji Machinery, GMA Packaging Machinery, Grandi, Impianti Novopac, Klikwood Corporation, LoeschPack, OCME, ROVEMA, Waldner |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |