What is Automated Tangential Flow Filtration (TFF) Systems - Global Market?

Automated Tangential Flow Filtration (TFF) Systems are a sophisticated technology used in the separation and purification processes across various industries, particularly in biotechnology and pharmaceuticals. These systems are designed to efficiently filter and concentrate biological solutions by allowing the liquid to flow tangentially across the surface of the filter membrane. This method minimizes the clogging of the filter, which is a common issue in traditional filtration systems. The global market for Automated TFF Systems is expanding as industries increasingly seek efficient and scalable solutions for their filtration needs. The demand is driven by the growing biopharmaceutical sector, which requires high-purity products and efficient processing methods. Automated TFF Systems offer advantages such as reduced processing time, improved product yield, and enhanced scalability, making them an attractive option for manufacturers. As the technology continues to evolve, these systems are becoming more user-friendly and cost-effective, further fueling their adoption across the globe. The market is characterized by a diverse range of products catering to different volume requirements, from small-scale laboratory setups to large-scale industrial applications. This versatility ensures that Automated TFF Systems remain a vital component in the toolkit of modern bioprocessing.

Below 200L, 200-500L, Above 500L in the Automated Tangential Flow Filtration (TFF) Systems - Global Market:

In the global market for Automated Tangential Flow Filtration (TFF) Systems, the categorization based on volume capacity—Below 200L, 200-500L, and Above 500L—plays a crucial role in addressing the diverse needs of different industries. Systems with a capacity Below 200L are typically used in laboratory settings and small-scale production environments. These systems are ideal for research and development purposes, where precision and flexibility are paramount. They allow researchers to experiment with various filtration parameters and optimize processes before scaling up to larger volumes. The compact size and ease of use make them a popular choice for academic institutions and small biotech firms. On the other hand, systems with a capacity of 200-500L are designed for medium-scale production. These systems strike a balance between capacity and operational efficiency, making them suitable for pilot-scale production and small to medium-sized biopharmaceutical companies. They offer the flexibility to handle a range of applications, from protein purification to cell harvesting, and are often used in clinical trial production. The ability to process larger volumes without compromising on quality or efficiency is a key advantage of these systems. For large-scale industrial applications, systems with a capacity Above 500L are essential. These systems are engineered to handle high-volume production demands, making them indispensable for large biopharmaceutical manufacturers. They are designed to integrate seamlessly into existing production lines, offering robust performance and reliability. The scalability of these systems allows manufacturers to meet increasing production demands without significant changes to their infrastructure. Additionally, the automation features of these systems reduce the need for manual intervention, thereby minimizing the risk of human error and ensuring consistent product quality. The global market for Automated TFF Systems is witnessing a growing demand for these high-capacity systems as the biopharmaceutical industry continues to expand. The ability to efficiently process large volumes of biological materials is critical for meeting the rising demand for biopharmaceutical products, such as vaccines and monoclonal antibodies. As a result, manufacturers are investing in advanced TFF systems that offer enhanced performance, scalability, and cost-effectiveness. The market is also seeing innovations in membrane technology and system design, further enhancing the capabilities of these systems. In conclusion, the categorization of Automated TFF Systems based on volume capacity is a key factor in addressing the diverse needs of the global market. From small-scale laboratory systems to large-scale industrial solutions, these systems offer the flexibility and efficiency required to meet the demands of modern bioprocessing. As the market continues to evolve, the demand for advanced TFF systems is expected to grow, driven by the increasing need for high-quality biopharmaceutical products.

Laboratory, Biopharmaceutical Manufacturers, Others in the Automated Tangential Flow Filtration (TFF) Systems - Global Market:

Automated Tangential Flow Filtration (TFF) Systems are utilized across various sectors, with significant applications in laboratories, biopharmaceutical manufacturing, and other industries. In laboratory settings, these systems are invaluable for research and development activities. They enable scientists to conduct experiments on a small scale, allowing for the precise control of filtration parameters. This precision is crucial for optimizing processes and developing new products. Laboratories benefit from the flexibility and ease of use of Automated TFF Systems, which can be adapted to a wide range of applications, from protein purification to virus concentration. The ability to quickly and efficiently process small volumes of biological materials makes these systems an essential tool for researchers. In the biopharmaceutical manufacturing sector, Automated TFF Systems play a critical role in the production of high-purity products. These systems are used to concentrate and purify biological solutions, ensuring that the final product meets stringent quality standards. The automation features of these systems reduce the need for manual intervention, minimizing the risk of contamination and ensuring consistent product quality. Biopharmaceutical manufacturers rely on these systems to streamline their production processes, improve product yield, and reduce processing time. The scalability of Automated TFF Systems allows manufacturers to easily transition from small-scale production to large-scale industrial applications, making them a versatile solution for the biopharmaceutical industry. Beyond laboratories and biopharmaceutical manufacturing, Automated TFF Systems find applications in other industries, such as food and beverage, water treatment, and chemical processing. In the food and beverage industry, these systems are used for the clarification and concentration of liquids, such as juices and dairy products. The ability to efficiently separate and concentrate components makes them an attractive option for manufacturers seeking to improve product quality and reduce waste. In the water treatment industry, Automated TFF Systems are used to remove impurities and contaminants from water, ensuring that it meets safety and quality standards. The chemical processing industry also benefits from the use of these systems, which are used to separate and purify chemical compounds. The versatility and efficiency of Automated TFF Systems make them a valuable asset across a wide range of industries. In conclusion, the usage of Automated Tangential Flow Filtration (TFF) Systems in laboratories, biopharmaceutical manufacturing, and other industries highlights their importance in modern processing and production. These systems offer the precision, efficiency, and scalability required to meet the demands of various applications, from research and development to large-scale industrial production. As industries continue to seek innovative solutions for their filtration needs, the demand for Automated TFF Systems is expected to grow, driven by their ability to deliver high-quality results and improve operational efficiency.

Automated Tangential Flow Filtration (TFF) Systems - Global Market Outlook:

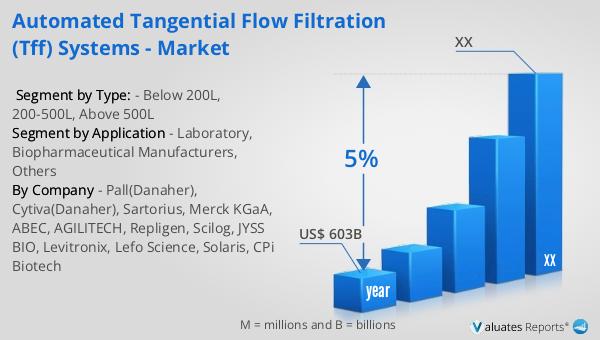

Our research indicates that the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth trajectory underscores the increasing demand for medical devices across various healthcare sectors. The expansion is driven by several factors, including technological advancements, an aging global population, and the rising prevalence of chronic diseases. As healthcare systems worldwide strive to improve patient outcomes and reduce costs, the adoption of innovative medical devices is becoming increasingly important. The market encompasses a wide range of products, from diagnostic equipment and surgical instruments to wearable health monitors and implantable devices. Each of these segments is experiencing growth as healthcare providers and patients alike recognize the benefits of advanced medical technologies. The projected growth rate of 5% reflects the dynamic nature of the medical device industry, which is characterized by rapid innovation and evolving regulatory landscapes. Companies operating in this market are investing heavily in research and development to bring new and improved products to market, while also navigating complex regulatory requirements. As a result, the global medical device market is poised for continued expansion, offering significant opportunities for companies that can successfully innovate and adapt to changing market conditions.

| Report Metric | Details |

| Report Name | Automated Tangential Flow Filtration (TFF) Systems - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Pall(Danaher), Cytiva(Danaher), Sartorius, Merck KGaA, ABEC, AGILITECH, Repligen, Scilog, JYSS BIO, Levitronix, Lefo Science, Solaris, CPi Biotech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |