What is Aircraft Wire & Cable - Global Market?

Aircraft wire and cable play a crucial role in the aviation industry, serving as the backbone for electrical systems in aircraft. These components are essential for transmitting power and signals across various parts of an aircraft, ensuring that everything from navigation systems to in-flight entertainment operates smoothly. The global market for aircraft wire and cable is driven by the increasing demand for new aircraft, advancements in technology, and the need for efficient and reliable electrical systems. As airlines expand their fleets and upgrade existing aircraft, the demand for high-quality wire and cable solutions continues to grow. Additionally, the push for more fuel-efficient and environmentally friendly aircraft has led to innovations in wire and cable materials, making them lighter and more durable. This market encompasses a wide range of products, including power cables, data cables, and specialty cables designed to withstand the harsh conditions of flight. With the aviation industry poised for growth, the aircraft wire and cable market is set to expand, offering numerous opportunities for manufacturers and suppliers to innovate and meet the evolving needs of the industry.

PVC insulated wires, PTFE insulated wires, Other in the Aircraft Wire & Cable - Global Market:

PVC insulated wires are a popular choice in the aircraft wire and cable market due to their excellent insulation properties and cost-effectiveness. Polyvinyl chloride (PVC) is a versatile material that provides good resistance to moisture, chemicals, and abrasion, making it suitable for various applications within an aircraft. These wires are commonly used in non-critical areas where flexibility and durability are required. However, PVC insulated wires have limitations, particularly in high-temperature environments, as they can degrade over time. On the other hand, PTFE insulated wires, made from polytetrafluoroethylene, offer superior performance in extreme conditions. PTFE is known for its high-temperature resistance, excellent electrical properties, and low friction, making it ideal for critical applications in aircraft where reliability is paramount. These wires are often used in areas exposed to high heat or where minimal signal loss is crucial. Besides PVC and PTFE, the aircraft wire and cable market also includes other insulation materials such as ETFE (ethylene tetrafluoroethylene), which provides a balance between performance and cost. ETFE insulated wires are lightweight, resistant to chemicals, and can withstand a wide range of temperatures, making them suitable for various aircraft applications. Each type of insulation material offers unique benefits, and the choice depends on the specific requirements of the aircraft system. As the aviation industry continues to evolve, the demand for advanced insulation materials that enhance performance and safety will drive innovation in the aircraft wire and cable market. Manufacturers are constantly exploring new materials and technologies to meet the stringent standards of the aerospace sector, ensuring that aircraft systems remain efficient, reliable, and safe.

Civil Aircraft, Military Aircraft in the Aircraft Wire & Cable - Global Market:

Aircraft wire and cable are integral to both civil and military aircraft, serving as the nervous system that connects various electronic components and systems. In civil aircraft, these wires and cables are used extensively to support a wide range of functions, from powering the cockpit instruments to enabling passenger amenities like lighting and entertainment systems. The complexity of modern civil aircraft requires a sophisticated network of wires and cables to ensure seamless communication and power distribution. As airlines strive to enhance passenger experience and operational efficiency, the demand for advanced wire and cable solutions continues to rise. In military aircraft, the requirements for wire and cable are even more stringent due to the demanding environments and critical missions they undertake. Military aircraft rely on robust and reliable wiring systems to support navigation, communication, weapons systems, and other mission-critical functions. The harsh conditions encountered during military operations, such as extreme temperatures, vibrations, and electromagnetic interference, necessitate the use of specialized wire and cable materials that can withstand these challenges. Additionally, the need for stealth and advanced avionics in military aircraft drives the demand for lightweight and low-profile wiring solutions. Both civil and military aircraft benefit from advancements in wire and cable technology, which enhance performance, reduce weight, and improve safety. As the aviation industry continues to innovate, the role of aircraft wire and cable in supporting the next generation of aircraft will be pivotal, ensuring that both civil and military aviation can meet the demands of the future.

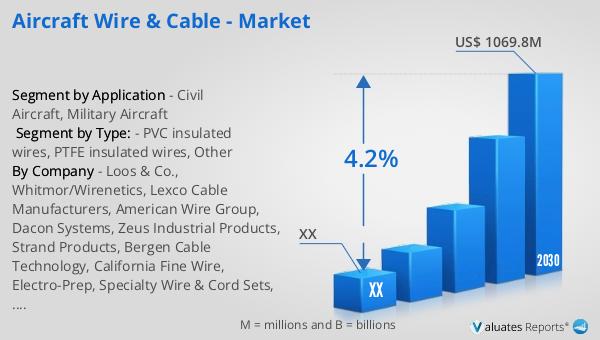

Aircraft Wire & Cable - Global Market Outlook:

The global market for aircraft wire and cable was valued at approximately $798 million in 2023, with projections indicating a growth to around $1,069.8 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.2% from 2024 to 2030. The North American segment of this market also shows promising potential, although specific figures for 2023 and 2030 were not provided. The anticipated growth in this region is expected to align with the global trend, driven by the increasing demand for new aircraft and the modernization of existing fleets. The steady growth rate reflects the ongoing advancements in aircraft technology and the continuous need for efficient and reliable electrical systems. As the aviation industry expands, the demand for high-quality wire and cable solutions will continue to rise, offering opportunities for manufacturers and suppliers to innovate and meet the evolving needs of the market. The focus on sustainability and fuel efficiency in aircraft design further underscores the importance of advanced wire and cable materials that contribute to lighter and more efficient aircraft. This market outlook highlights the significant role that aircraft wire and cable play in the aviation sector, driving growth and innovation in the industry.

| Report Metric | Details |

| Report Name | Aircraft Wire & Cable - Market |

| Forecasted market size in 2030 | US$ 1069.8 million |

| CAGR | 4.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Loos & Co., Whitmor/Wirenetics, Lexco Cable Manufacturers, American Wire Group, Dacon Systems, Zeus Industrial Products, Strand Products, Bergen Cable Technology, California Fine Wire, Electro-Prep, Specialty Wire & Cord Sets, Interconnect Cable Technologies Corp., Multi/Cable Corp |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |