What is AGV for Pharmaceutical Industry - Global Market?

Automated Guided Vehicles (AGVs) are revolutionizing the pharmaceutical industry by enhancing efficiency and accuracy in material handling and logistics. These driverless vehicles are equipped with advanced navigation systems that allow them to transport materials within manufacturing facilities and warehouses without human intervention. In the pharmaceutical sector, AGVs are particularly valuable due to their ability to maintain the integrity and security of sensitive products. They help in reducing human error, ensuring that the right materials are delivered to the right place at the right time. This is crucial in an industry where precision and timing are vital. AGVs also contribute to cost savings by reducing labor costs and minimizing product damage. As the global market for pharmaceuticals continues to grow, the demand for AGVs is expected to rise, driven by the need for more efficient and reliable logistics solutions. The integration of AGVs in pharmaceutical operations not only streamlines processes but also supports compliance with stringent regulatory standards, making them an indispensable tool in modern pharmaceutical manufacturing and distribution.

Unit Load Type, Automated Forklift Type, Tugger Type, Others in the AGV for Pharmaceutical Industry - Global Market:

In the realm of Automated Guided Vehicles (AGVs) for the pharmaceutical industry, various types cater to different operational needs, each offering unique advantages. The Unit Load Type AGVs are designed to transport large, singular loads such as pallets or containers. These AGVs are particularly beneficial in environments where bulk materials need to be moved efficiently and safely. They are equipped with platforms or forks that can lift and carry heavy loads, making them ideal for transporting raw materials or finished products within a facility. Automated Forklift Type AGVs, on the other hand, mimic the functions of traditional forklifts but operate autonomously. These AGVs are adept at handling tasks that involve stacking, unstacking, and moving pallets. They are equipped with sensors and cameras to navigate complex environments, ensuring safety and precision in operations. Tugger Type AGVs are designed to pull carts or trailers, making them suitable for applications where multiple loads need to be moved simultaneously. This type of AGV is often used in production lines to transport materials between different stages of manufacturing. Lastly, there are other specialized AGVs that cater to specific needs within the pharmaceutical industry. These may include AGVs designed for cleanroom environments, where maintaining sterility is paramount, or those equipped with advanced tracking systems for high-value or sensitive products. Each type of AGV plays a crucial role in optimizing logistics and material handling in the pharmaceutical sector, contributing to increased efficiency, reduced labor costs, and enhanced safety. As the industry continues to evolve, the versatility and adaptability of AGVs will be key in meeting the diverse needs of pharmaceutical operations.

Warehouse, Production Line, Other in the AGV for Pharmaceutical Industry - Global Market:

The use of Automated Guided Vehicles (AGVs) in the pharmaceutical industry spans various critical areas, including warehouses, production lines, and other specialized environments. In warehouses, AGVs are instrumental in automating the storage and retrieval of materials. They efficiently navigate through aisles, picking up and delivering pallets or containers to designated locations. This automation not only speeds up the process but also reduces the risk of human error, ensuring that the right products are stored and retrieved accurately. AGVs in warehouses also contribute to better space utilization, as they can operate in narrower aisles compared to traditional forklifts. On production lines, AGVs play a vital role in ensuring a seamless flow of materials between different stages of manufacturing. They transport raw materials to production areas and move finished products to packaging or storage areas. This automation helps in maintaining a continuous production process, minimizing downtime and increasing overall productivity. AGVs can be programmed to follow specific routes and schedules, ensuring timely delivery of materials and reducing bottlenecks in production. Beyond warehouses and production lines, AGVs are also used in other specialized areas within the pharmaceutical industry. For instance, in cleanroom environments, AGVs are designed to operate without compromising sterility, transporting materials without human contact. They are also used in distribution centers to automate the sorting and dispatching of products, ensuring timely delivery to customers. The integration of AGVs in these areas not only enhances operational efficiency but also supports compliance with regulatory standards, as they provide accurate tracking and documentation of material movements. Overall, the use of AGVs in the pharmaceutical industry is a testament to the growing trend of automation, offering significant benefits in terms of efficiency, accuracy, and safety.

AGV for Pharmaceutical Industry - Global Market Outlook:

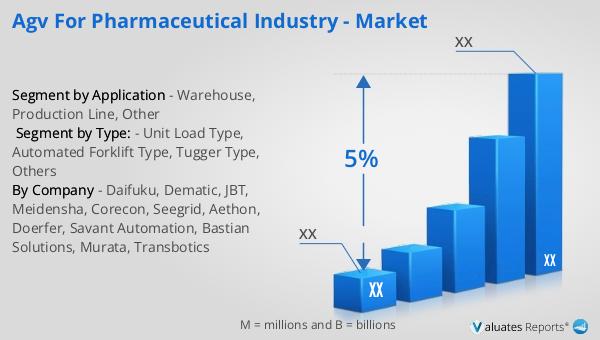

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, reflecting a steady growth trajectory with a compound annual growth rate (CAGR) of 5% projected over the next six years. This growth is indicative of the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, rising prevalence of chronic diseases, and advancements in drug development. In comparison, the chemical drug market has also shown significant growth, expanding from 1,005 billion USD in 2018 to an estimated 1,094 billion USD in 2022. This increase highlights the sustained demand for chemical drugs, which continue to play a crucial role in healthcare despite the rise of biologics and other innovative therapies. The growth in both the pharmaceutical and chemical drug markets underscores the importance of efficient logistics and material handling solutions, such as Automated Guided Vehicles (AGVs), to support the expanding industry. As the market continues to evolve, the adoption of AGVs is expected to rise, driven by the need for more efficient and reliable logistics solutions that can keep pace with the growing demand for pharmaceutical products.

| Report Metric | Details |

| Report Name | AGV for Pharmaceutical Industry - Market |

| CAGR | 5% |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Daifuku, Dematic, JBT, Meidensha, Corecon, Seegrid, Aethon, Doerfer, Savant Automation, Bastian Solutions, Murata, Transbotics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |