What is Global Underwater Pelletizer Market?

The Global Underwater Pelletizer Market refers to the industry focused on the production and sale of underwater pelletizers, which are specialized machines used to convert molten polymers into small, uniformly sized pellets. These pellets are essential in various manufacturing processes, particularly in the plastics and petrochemical industries. Underwater pelletizers operate by extruding molten polymer through a die plate into a water bath, where the polymer strands are immediately cut into pellets by rotating knives. The water cools and solidifies the pellets, which are then dried and collected for further processing or sale. This market encompasses a wide range of equipment, from small-scale machines for niche applications to large, industrial-grade systems designed for high-volume production. The demand for underwater pelletizers is driven by the growing need for high-quality, consistent pellets in various applications, including plastic manufacturing, recycling, and compounding. Technological advancements and the increasing focus on sustainability and efficiency are also key factors influencing the market's growth.

Strand Palletizing System, Underwater Palletizing System in the Global Underwater Pelletizer Market:

The Strand Pelletizing System and the Underwater Pelletizing System are two primary methods used in the Global Underwater Pelletizer Market. The Strand Pelletizing System involves extruding molten polymer through a die plate to form continuous strands, which are then cooled in a water bath or air-cooled before being cut into pellets by a pelletizer. This system is known for its simplicity and cost-effectiveness, making it suitable for a wide range of applications, including the production of various thermoplastics. However, it can be less efficient for high-output operations due to the need for manual handling of the strands and potential issues with strand breakage. On the other hand, the Underwater Pelletizing System offers a more advanced and efficient solution. In this system, the molten polymer is extruded through a die plate directly into a water chamber, where rotating knives cut the polymer into pellets immediately upon extrusion. The water cools and solidifies the pellets, which are then separated from the water and dried. This method provides several advantages over the Strand Pelletizing System, including higher throughput, better pellet quality, and reduced labor requirements. The underwater process ensures that the pellets are uniformly shaped and sized, which is crucial for applications requiring high precision and consistency. Both systems have their unique advantages and are chosen based on specific production needs and material characteristics. The Strand Pelletizing System is often preferred for its lower initial investment and ease of operation, while the Underwater Pelletizing System is favored for its efficiency and ability to handle high-output production with minimal manual intervention. The choice between these systems depends on factors such as the type of polymer being processed, the desired pellet size and shape, production volume, and overall cost considerations. In the context of the Global Underwater Pelletizer Market, these systems are continually evolving with advancements in technology and materials. Innovations such as improved die plate designs, more efficient cooling systems, and automated control systems are enhancing the performance and reliability of both Strand and Underwater Pelletizing Systems. Additionally, the increasing focus on sustainability and energy efficiency is driving the development of more eco-friendly pelletizing solutions, further expanding the market's potential. Overall, the Strand Pelletizing System and the Underwater Pelletizing System play crucial roles in the Global Underwater Pelletizer Market, catering to diverse industrial needs and contributing to the production of high-quality polymer pellets. As industries continue to demand more efficient and reliable pelletizing solutions, these systems are expected to see continued growth and innovation.

Petrochemical Industry, Plastics recycling industry, Others in the Global Underwater Pelletizer Market:

The Global Underwater Pelletizer Market finds extensive usage in various industries, including the petrochemical industry, plastics recycling industry, and others. In the petrochemical industry, underwater pelletizers are essential for converting raw polymer materials into pellets that can be easily transported, stored, and further processed into a wide range of plastic products. The uniform size and shape of the pellets produced by underwater pelletizers ensure consistent quality and performance in downstream applications, such as injection molding, extrusion, and blow molding. This consistency is crucial for maintaining the high standards required in the production of automotive parts, packaging materials, consumer goods, and other plastic products. In the plastics recycling industry, underwater pelletizers play a vital role in transforming recycled plastic materials into reusable pellets. The recycling process involves collecting and sorting plastic waste, cleaning and shredding it into smaller pieces, and then melting it down to form new pellets. Underwater pelletizers are particularly effective in this process because they can handle a wide variety of plastic types and grades, ensuring that the recycled pellets meet the necessary quality standards for reuse in manufacturing. This capability is increasingly important as the demand for sustainable and eco-friendly products grows, driving the need for efficient recycling solutions. Beyond the petrochemical and plastics recycling industries, underwater pelletizers are also used in other sectors where precise and consistent pellet production is required. For example, in the pharmaceutical industry, underwater pelletizers are used to produce uniform pellets of active pharmaceutical ingredients (APIs) and excipients, which are then used in the formulation of various medications. The food industry also utilizes underwater pelletizers to create pellets of food additives, flavorings, and other ingredients that require precise dosing and uniformity. Additionally, underwater pelletizers are employed in the production of specialty chemicals, adhesives, and coatings, where the quality and consistency of the pellets are critical to the performance of the final products. The versatility and efficiency of underwater pelletizers make them indispensable in these industries, contributing to improved product quality, reduced waste, and enhanced production efficiency. As industries continue to evolve and demand more sustainable and efficient manufacturing processes, the role of underwater pelletizers in these applications is expected to grow. The ongoing advancements in pelletizing technology, such as the development of more energy-efficient systems and the integration of automation and digital controls, are further enhancing the capabilities and appeal of underwater pelletizers across various sectors.

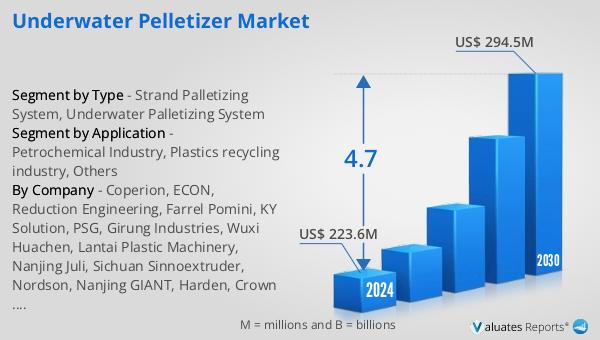

Global Underwater Pelletizer Market Outlook:

The global Underwater Pelletizer market is anticipated to expand from US$ 223.6 million in 2024 to US$ 294.5 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 4.7% over the forecast period. China stands as the largest market for underwater pelletizers, holding approximately 54% of the market share. The United States follows, accounting for about 19% of the market share. The top three companies in this sector collectively occupy around 22% of the market share.

| Report Metric | Details |

| Report Name | Underwater Pelletizer Market |

| Accounted market size in 2024 | US$ 223.6 million |

| Forecasted market size in 2030 | US$ 294.5 million |

| CAGR | 4.7 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Coperion, ECON, Reduction Engineering, Farrel Pomini, KY Solution, PSG, Girung Industries, Wuxi Huachen, Lantai Plastic Machinery, Nanjing Juli, Sichuan Sinnoextruder, Nordson, Nanjing GIANT, Harden, Crown Machine, Cowin Extrusion, Adlbut, Gala Industries, Chuangbo Machine, Margo Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |